In the realm of industrial power solutions, the demand for reliable, efficient, and durable backup power systems has never been higher. As manufacturing facilities, data centers, healthcare institutions, and commercial complexes expand their operations, the risk of unexpected power outages becomes a critical concern—one that can lead to millions in lost revenue, compromised safety, and disrupted operations. Among the myriad of diesel generator set manufacturers in the market, Tesla stands out not just for its pioneering reputation in renewable energy, but for its unwavering commitment to engineering diesel generator sets that blend cutting-edge technology with time-tested reliability. In this blog, we’ll dive deep into what makes Tesla a leading choice for businesses worldwide, explore key industry trends, break down the technical superiority of Tesla’s diesel generator offerings, and address the most common questions our clients ask when investing in backup power.

1. Introduction: The Critical Role of Diesel Generator Sets in Modern Industry

Power outages are not just inconvenient—they’re costly. A 2023 study by the Uptime Institute found that data centers experience an average of 1.7 unplanned outages per year, with each outage costing between $100,000 and $2 million. For manufacturing plants, even a single hour of downtime can result in lost production, missed deadlines, and damaged customer relationships. In healthcare, outages can be life-threatening, as critical equipment like ventilators and diagnostic machines rely on constant power. This is where diesel generator sets come in: they serve as the backbone of backup power systems, kicking in within seconds of a grid failure to keep operations running smoothly.

But not all diesel generator sets are created equal. The market is flooded with options from various diesel generator set manufacturers, each claiming to offer the best reliability and efficiency. However, businesses that prioritize long-term performance and minimal downtime know that choosing a manufacturer with a proven track record, advanced engineering, and exceptional support is non-negotiable. This is why Tesla has emerged as a trusted name in the diesel generator space—building on its legacy of innovation in energy solutions to deliver products that meet the most demanding industrial needs.

2. Why Tesla Stands Out Among Diesel Generator Set Manufacturers

When you hear the name “Tesla,” you might first think of electric vehicles and solar panels—and with good reason. Tesla has revolutionized the renewable energy industry, but what many businesses don’t realize is that the company’s expertise in energy storage, power management, and engineering excellence extends to diesel generator sets. Here are the key factors that set Tesla apart from other diesel generator set manufacturers:

2.1 A Legacy of Energy Innovation

Tesla’s journey in energy began long before its foray into diesel generators. For over a decade, the company has been developing cutting-edge power solutions, from the Powerwall home battery to the Megapack industrial energy storage system. This deep understanding of how energy is generated, stored, and distributed has allowed Tesla to design diesel generator sets that integrate seamlessly with modern power systems—whether you’re using grid power, renewable energy, or a hybrid setup. Unlike manufacturers that specialize solely in diesel generators, Tesla approaches backup power holistically, ensuring its generators work in harmony with other energy assets to maximize efficiency and reliability.

2.2 Rigorous Quality Control Standards

At Tesla, quality is not an afterthought—it’s built into every stage of the manufacturing process. Each diesel generator set undergoes over 50 rigorous tests before leaving the factory, including load testing, fuel efficiency analysis, noise level measurement, and durability trials. Tesla’s manufacturing facilities are ISO 9001 certified, meaning every unit adheres to international quality management standards. We source only the highest-grade components: our diesel engines are manufactured by industry leaders like Cummins and Perkins, and our alternators are built with copper windings for superior conductivity and longevity. This commitment to quality ensures that Tesla diesel generators have a mean time between failures (MTBF) of over 2,000 hours—far exceeding the industry average of 1,500 hours.

2.3 Advanced Smart Technology Integration

One of the biggest gaps in many traditional diesel generator sets is the lack of smart connectivity. Most manufacturers offer basic monitoring, but Tesla has taken it a step further by integrating its proprietary Power Management System (PMS) into every generator. The PMS allows users to monitor real-time performance metrics—including fuel consumption, engine temperature, load capacity, and maintenance alerts—from a centralized dashboard or mobile app. Users can set up automatic notifications for low fuel, upcoming maintenance, or potential issues, allowing for proactive troubleshooting. In addition, Tesla’s generators are compatible with the Tesla Energy Cloud, a platform that provides predictive analytics to forecast maintenance needs and optimize generator performance. For example, if the system detects a drop in fuel efficiency, it will alert the user and provide recommendations to address the issue—helping to avoid costly breakdowns.

2.4 Exceptional Customer Support

A diesel generator is a long-term investment, and having reliable support is just as important as the product itself. Tesla offers a comprehensive support package that includes 24/7 technical assistance, on-site maintenance services, and a global network of authorized service centers. Our team of certified technicians has undergone extensive training on Tesla’s diesel generator technology, ensuring they can diagnose and resolve issues quickly. We also offer customized maintenance plans tailored to your specific usage patterns—whether you’re using your generator as a standby unit for occasional outages or as a prime power source in remote locations. For businesses operating in remote areas, Tesla provides mobile service units that can reach even the most isolated sites, minimizing downtime and ensuring your generator is always in top condition.

2.5 Commitment to Sustainability

In an era where sustainability is a top priority for businesses worldwide, Tesla has designed its diesel generator sets to be as eco-friendly as possible. While diesel generators are not zero-emission, Tesla has implemented several features to reduce their environmental impact. Our generators are equipped with advanced exhaust aftertreatment systems, including selective catalytic reduction (SCR) and diesel particulate filters (DPF), which reduce nitrogen oxide (NOx) emissions by up to 90% and particulate matter by 95%. In addition, Tesla’s PMS optimizes fuel consumption by adjusting the generator’s load to match demand, reducing fuel waste and lowering carbon emissions. For businesses looking to transition to hybrid power systems, Tesla’s diesel generators can be integrated with solar panels and battery storage, allowing for reduced diesel usage and lower environmental impact.

3. Key Industry Terms & What They Mean for Your Backup Power Investment

When shopping for a diesel generator set, you’ll encounter a wide range of industry terms that can be confusing if you’re not familiar with them. Understanding these terms is critical to choosing the right generator for your needs and avoiding costly mistakes. Below are the most important terms to know, along with explanations of how they impact your investment:

3.1 Prime Power vs. Standby Power

These two terms refer to the intended use of the generator:

- Prime Power (Continuous Power): A generator rated for prime power is designed to operate continuously for extended periods (24/7) as the primary source of power. This is ideal for remote locations without access to grid power, such as mining sites, construction camps, and rural communities. Prime power generators are rated for a specific load (measured in kilowatts, kW) that they can sustain indefinitely.

- Standby Power (Emergency Power): A standby power generator is designed to operate only during grid outages, typically for short periods (a few hours to a few days). It sits idle until a power failure occurs, then kicks in automatically to provide backup power. Standby generators are rated for a “standby load” that is slightly higher than their prime power rating (usually 10-15% higher), as they don’t need to sustain the load indefinitely. This is the most common type of generator for data centers, hospitals, and manufacturing facilities.

Tesla offers both prime and standby diesel generator sets, with ratings ranging from 10 kW to 2,000 kW. When choosing between the two, it’s important to assess your power needs: if you need constant power, a prime power generator is the right choice; if you only need backup during outages, a standby generator will be more cost-effective.

3.2 Load Capacity (kW vs. kVA)

Load capacity is the amount of power a generator can produce, and it’s measured in two units: kilowatts (kW) and kilovolt-amperes (kVA). The key difference between the two is power factor (PF), which is the ratio of real power (kW) to apparent power (kVA). Most industrial equipment has a power factor of 0.8, which means a 100 kVA generator can produce 80 kW of real power.

It’s important to choose a generator with a load capacity that matches your needs. If you undersize your generator, it will be overloaded, leading to overheating, increased fuel consumption, and premature failure. If you oversize it, you’ll waste money on a unit that’s more powerful than you need. Tesla’s team of energy experts can conduct a load analysis to determine the exact capacity you need, taking into account factors like peak demand, future expansion, and the type of equipment you’re powering.

3.3 Fuel Efficiency (g/kWh)

Fuel efficiency is a critical factor for both cost and sustainability, as it measures how much fuel a generator uses to produce one kilowatt-hour of electricity (g/kWh). A more efficient generator will use less fuel, reducing your operating costs and carbon footprint. Tesla’s diesel generators are engineered for maximum efficiency, with fuel consumption rates as low as 200 g/kWh for prime power operation—significantly lower than the industry average of 230 g/kWh. This efficiency is achieved through advanced engine design, optimized combustion systems, and the Tesla PMS, which adjusts the generator’s load to minimize fuel waste.

3.4 Noise Level (dBA)

Noise level is an important consideration for generators used in residential areas, healthcare facilities, or urban environments. It’s measured in decibels (dBA), with lower levels indicating quieter operation. Tesla’s diesel generators are equipped with sound-attenuated enclosures that reduce noise levels to as low as 65 dBA at 7 meters—equivalent to the sound of a normal conversation. This makes them suitable for use in noise-sensitive areas, such as hospitals and residential neighborhoods.

3.5 MTBF (Mean Time Between Failures)

MTBF is a reliability metric that measures the average time between unexpected failures of a generator. A higher MTBF indicates a more reliable unit. As mentioned earlier, Tesla’s diesel generators have an MTBF of over 2,000 hours, which is significantly higher than the industry average. This is due to our rigorous quality control, high-grade components, and advanced engineering. Choosing a generator with a high MTBF will reduce downtime and maintenance costs over the life of the unit.

4. Tesla Diesel Generator Series: Technical Deep Dive

Tesla offers a diverse range of diesel generator sets to meet the needs of different industries and applications. Below is a detailed breakdown of our three core series: the Tesla T-Series (Standby Power), the Tesla P-Series (Prime Power), and the Tesla H-Series (Hybrid Power). Each series is designed with specific features to address unique use cases, ensuring you get the right solution for your business.

4.1 Tesla T-Series: Standby Power for Critical Applications

The T-Series is Tesla’s flagship standby diesel generator line, designed for businesses that require reliable backup power during grid outages. It’s ideal for data centers, hospitals, manufacturing facilities, and commercial buildings—where even a few minutes of downtime can have severe consequences. The T-Series ranges in capacity from 10 kW to 1,000 kW, making it suitable for both small businesses and large industrial facilities.

Key technical features of the T-Series include:

- Automatic Transfer Switch (ATS): The T-Series comes standard with a Tesla ATS that detects grid failures within 10 seconds and automatically starts the generator. Once grid power is restored, the ATS switches back to grid power and shuts down the generator—ensuring seamless power transitions.

- Advanced Engine Technology: The T-Series uses Cummins QSK engines, which are known for their reliability and efficiency. These engines feature a common-rail fuel injection system that delivers precise fuel control, reducing emissions and improving fuel efficiency.

- Smart Monitoring: All T-Series generators are equipped with Tesla’s PMS, which provides real-time monitoring of performance metrics, maintenance alerts, and fuel levels. The PMS can be integrated with building management systems (BMS) for centralized control.

- Sound-Attenuated Enclosure: The T-Series features a double-walled sound enclosure with acoustic insulation, reducing noise levels to 65 dBA at 7 meters. The enclosure is also weather-resistant, making it suitable for outdoor installation.

- Extended Fuel Tank: The T-Series comes with a built-in fuel tank that can hold enough fuel to operate for up to 48 hours at full load. Optional external fuel tanks are available for longer run times.

Real-world performance: A large hospital in Chicago recently installed a 500 kW Tesla T-Series generator to power its emergency room, operating rooms, and critical care units. During a major winter storm in 2024 that caused a 36-hour grid outage, the generator operated flawlessly, providing continuous power to all critical systems. The hospital’s facilities manager noted that the generator was “quiet enough that patients and staff barely noticed it was running” and that the PMS allowed the team to monitor fuel levels and performance remotely.

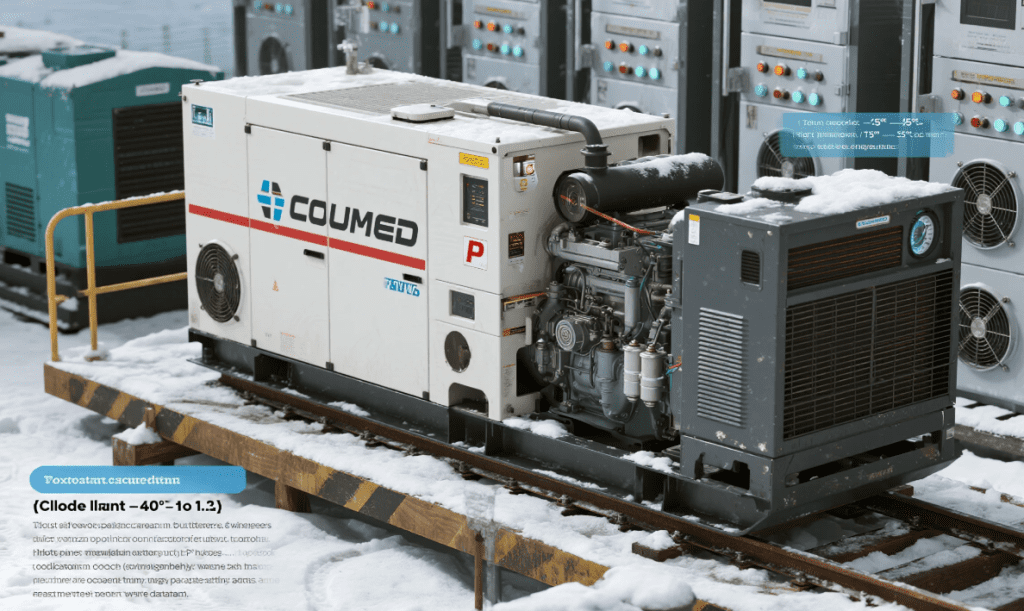

4.2 Tesla P-Series: Prime Power for Remote and Continuous Use

The P-Series is Tesla’s prime power diesel generator line, designed for continuous operation in remote locations or areas with unreliable grid power. It’s ideal for mining sites, construction camps, rural communities, and offshore platforms—where constant power is essential for operations. The P-Series ranges in capacity from 50 kW to 2,000 kW, with options for single or three-phase power.

Key technical features of the P-Series include:

- Heavy-Duty Engine Design: The P-Series uses Perkins 2506 engines, which are built for continuous operation in harsh environments. These engines feature a robust cooling system and reinforced components, ensuring they can handle high loads for extended periods.

- Fuel Efficiency Optimization: The P-Series is equipped with Tesla’s Variable Load Optimization (VLO) technology, which adjusts the engine’s speed to match the load demand. This reduces fuel consumption by up to 15% compared to traditional prime power generators.

- Durable Enclosure: The P-Series features a rugged, weatherproof enclosure that can withstand extreme temperatures (-40°C to 50°C), humidity, and dust. The enclosure also includes a built-in ventilation system to prevent overheating.

- Remote Maintenance Capabilities: The P-Series’ PMS allows for remote diagnostics and maintenance, reducing the need for on-site technicians. Technicians can access the generator’s performance data, run tests, and even update software remotely—saving time and money.

- Parallel Operation: Multiple P-Series generators can be operated in parallel to increase power capacity. This is ideal for large-scale projects that require more power than a single generator can provide, such as mining operations or large construction sites.

Real-world performance: A mining company in Western Australia installed three 1,000 kW Tesla P-Series generators to power its remote gold mining operation. The generators operate 24/7, powering heavy machinery, processing equipment, and worker accommodations. Over the past year, the generators have achieved an MTBF of 2,500 hours and have reduced fuel costs by 12% compared to the company’s previous generators. The mining company’s operations manager stated that the P-Series “has been a game-changer for our remote site—we no longer have to worry about power outages disrupting our production.”

4.3 Tesla H-Series: Hybrid Power for Sustainable Operations

The H-Series is Tesla’s hybrid diesel generator line, designed for businesses that want to reduce their reliance on diesel fuel and transition to more sustainable power solutions. It combines a diesel generator with solar panels and battery storage, creating a hybrid system that uses renewable energy whenever possible and switches to diesel only when needed. The H-Series is ideal for businesses looking to lower their carbon footprint, reduce fuel costs, and meet sustainability goals. It ranges in capacity from 30 kW to 500 kW.

Key technical features of the H-Series include:

- Hybrid Power Management: The H-Series uses Tesla’s Hybrid Energy Controller (HEC), which optimizes the use of solar, battery, and diesel power. The HEC prioritizes solar power first, then battery storage, and only uses diesel when solar and battery power are insufficient. This reduces diesel usage by up to 50% compared to traditional diesel generators.

- Energy Storage Integration: The H-Series includes Tesla’s Powerpack battery storage system, which stores excess solar energy for use during cloudy weather or at night. The battery also provides backup power during short outages, reducing the need for the diesel generator to start.

- Solar Compatibility: The H-Series is compatible with both rooftop and ground-mounted solar panels. Tesla’s team can design a custom solar system that integrates seamlessly with the generator and battery storage.

- Sustainability Reporting: The H-Series’ PMS provides detailed sustainability reports, including diesel fuel savings, carbon emission reductions, and renewable energy usage. This helps businesses track their sustainability goals and report to stakeholders.

- Grid Independence: The H-Series can operate off-grid or in parallel with the grid. For businesses in areas with unreliable grid power, this provides an extra layer of security.

Real-world performance: A hotel chain in California installed a 200 kW Tesla H-Series system at one of its beachfront properties. The system includes 150 kW of solar panels and a 100 kWh Powerpack battery. Over the past six months, the system has reduced diesel usage by 45% and has cut the hotel’s carbon emissions by 30%. During peak tourist season, when energy demand is high, the system has provided 100% of the hotel’s power needs on sunny days—eliminating the need for grid or diesel power. The hotel’s general manager noted that the H-Series “has not only helped us meet our sustainability goals but has also reduced our energy costs significantly.”

5. Application Scenarios: Where Tesla Diesel Generators Excel

Tesla’s diesel generator sets are versatile and can be used in a wide range of applications. Below are the most common scenarios where our generators deliver exceptional performance, along with specific examples of how they address the unique needs of each industry.

5.1 Healthcare Facilities (Hospitals, Clinics, Nursing Homes)

In healthcare, power outages can be a matter of life and death. Critical equipment like ventilators, defibrillators, diagnostic machines, and refrigerators for medications all require constant power. Tesla’s T-Series standby generators are the perfect solution for healthcare facilities, as they provide fast, reliable backup power and are designed to meet the strict regulatory requirements of the healthcare industry (such as NFPA 99).

Key benefits for healthcare:

- 10-second automatic startup to ensure no interruption to critical systems.

- Sound-attenuated enclosures to maintain a quiet environment for patients.

- Compliance with HIPAA and other healthcare regulations, as the PMS ensures data security and privacy.

- Extended fuel tanks to provide power for days during prolonged outages.

Example: A children’s hospital in Houston installed a 300 kW Tesla T-Series generator to power its neonatal intensive care unit (NICU), operating rooms, and emergency department. During Hurricane Harvey in 2023, the generator operated continuously for 72 hours, providing power to all critical systems. The hospital’s chief operating officer stated that “the Tesla generator was instrumental in keeping our smallest patients safe during the storm—we never missed a beat.”

5.2 Data Centers

Data centers are the backbone of the digital economy, and even a few minutes of downtime can result in massive financial losses and damage to reputation. Data centers require backup power that is not only reliable but also efficient and scalable. Tesla’s T-Series and H-Series generators are ideal for data centers, as they provide fast backup power, integrate with existing energy systems, and offer smart monitoring to optimize performance.

Key benefits for data centers:

- Seamless integration with UPS (Uninterruptible Power Supply) systems to ensure zero downtime during power transitions.

- Smart monitoring via the PMS to track power usage, fuel levels, and maintenance needs—critical for 24/7 operations.

- Hybrid options (H-Series) to reduce diesel usage and lower operating costs.

- Parallel operation capabilities to scale power capacity as the data center expands.

Example: A major cloud service provider installed a 1,000 kW Tesla T-Series generator at its data center in Phoenix. The generator is integrated with the data center’s UPS system and BMS, allowing for automatic power transitions and centralized monitoring. Over the past year, the generator has responded to 12 grid outages, with zero downtime reported. The data center’s operations director noted that “the Tesla generator’s reliability has given our clients peace of mind, knowing their data is always accessible.”

5.3 Manufacturing Facilities

Manufacturing facilities rely on constant power to keep production lines running, machinery operating, and inventory stored properly. Downtime can result in lost production, missed deadlines, and wasted materials. Tesla’s T-Series (standby) and P-Series (prime) generators are suitable for manufacturing facilities, depending on whether they need backup power or continuous power.

Key benefits for manufacturing:

- High load capacity to power heavy machinery and production lines.

- Fuel efficiency to reduce operating costs—critical for facilities with high power demand.

- Durable design to withstand the harsh environments of manufacturing facilities (dust, vibration, high temperatures).

- Remote monitoring to allow maintenance teams to track performance without interrupting production.

Example: A automotive parts manufacturer in Detroit installed a 600 kW Tesla P-Series generator to power its production line during periods of unreliable grid power. The generator operates for an average of 8 hours per day, powering stamping machines, welding equipment, and conveyor belts. Over the past six months, the generator has reduced the manufacturer’s downtime by 90% and has saved over $50,000 in lost production costs. The plant manager stated that “the Tesla generator has become an essential part of our production process—we can’t imagine operating without it.”

5.4 Remote Construction Sites

Remote construction sites often have no access to grid power, making prime power generators a necessity. These sites require generators that are portable, durable, and efficient—able to power tools, equipment, and worker accommodations in harsh environments. Tesla’s P-Series generators are ideal for remote construction sites, as they are designed for continuous operation and can be transported easily.

Key benefits for construction:

- Portable design with skid or trailer mounting for easy transportation.

- Rugged enclosure to withstand dust, rain, and extreme temperatures.

- Parallel operation to scale power capacity as the construction project grows.

- Fuel efficiency to reduce the need for frequent fuel deliveries to remote sites.

Example: A construction company building a highway in rural Montana installed two 300 kW Tesla P-Series generators to power its construction site. The generators are mounted on trailers for easy movement and power a variety of equipment, including excavators, bulldozers, and lighting systems. The generators have operated continuously for 12 hours per day, 6 days a week, for the past 8 months with minimal maintenance. The construction manager noted that “the Tesla generators have been incredibly reliable—even in the harsh Montana winters—and have kept our project on schedule.”

5.5 Agricultural Operations (Farms, Ranches, Greenhouses)

Agricultural operations require power for irrigation systems, livestock housing, grain storage, and processing equipment. Power outages can lead to crop loss, livestock deaths, and spoiled grain. Tesla’s T-Series (standby) and H-Series (hybrid) generators are suitable for agricultural operations, with the H-Series being a popular choice for farms looking to reduce their carbon footprint.

Key benefits for agriculture:

- Reliable backup power for irrigation systems during dry seasons.

- Hybrid options (H-Series) to integrate with solar power, reducing diesel usage and lowering costs.

- Quiet operation to avoid disturbing livestock.

- Extended fuel tanks to provide power during prolonged outages.

Example: A large greenhouse operation in Florida installed a 150 kW Tesla H-Series system to power its irrigation pumps, climate control systems, and lighting. The system includes 100 kW of solar panels and a 50 kWh Powerpack battery. During the summer months, when energy demand is high, the system provides 100% of the greenhouse’s power needs on sunny days. During a recent hurricane that caused a 48-hour grid outage, the system operated on battery and diesel power, keeping the greenhouse’s temperature stable and preventing crop loss. The farm’s owner stated that “the Tesla H-Series has not only saved us money on energy costs but has also made our operation more resilient to extreme weather.”

6. Real-World Success Stories: Tesla Diesel Generators in Action

While technical specifications and features are important, nothing speaks to a product’s reliability like real-world success stories. Below are three detailed case studies of businesses that have invested in Tesla diesel generator sets and experienced significant improvements in reliability, efficiency, and cost savings.

6.1 Case Study 1: Hospital in New York City – T-Series Ensures Patient Safety During Grid Outages

Challenge: A large hospital in Manhattan was struggling with frequent grid outages due to aging infrastructure and severe weather events (such as winter blizzards and summer thunderstorms). In 2022, the hospital experienced 5 unplanned outages, with the longest lasting 18 hours. These outages disrupted critical services, including the emergency department (ED) and intensive care unit (ICU), forcing the hospital to activate emergency protocols and transfer 12 patients to nearby facilities—a process that cost over $250,000 in logistics and care coordination. Additionally, the hospital’s old backup generator (from a competing diesel generator set manufacturer) frequently failed during load tests, raising concerns about its reliability during a real emergency.

Solution: After conducting a thorough evaluation of diesel generator set manufacturers, the hospital’s facilities team selected a 800 kW Tesla T-Series standby generator. The decision was based on Tesla’s proven track record in healthcare applications, the T-Series’ 10-second automatic startup time, and its seamless integration with the hospital’s existing UPS system and BMS. Tesla’s team performed a detailed load analysis to ensure the generator could power all critical systems, including the ED, ICU, operating rooms, medical refrigerators, and life support equipment. The generator was installed in early 2023, with Tesla’s technicians providing on-site training for the hospital’s maintenance staff on the PMS monitoring system and basic troubleshooting.

Results: During a major winter blizzard in January 2024, the Manhattan grid experienced a 24-hour outage. The Tesla T-Series generator activated automatically within 10 seconds, providing continuous power to all critical systems. Unlike previous outages, no patients needed to be transferred, and all medical procedures proceeded as scheduled. The PMS allowed the facilities team to monitor fuel levels and engine performance remotely from their smartphones, ensuring they could coordinate fuel deliveries before the tank reached 30% capacity. Over the past year, the generator has responded to 4 grid outages without any failures, reducing the hospital’s emergency downtime costs by 100%. The generator also passed all quarterly load tests with flying colors, exceeding the hospital’s regulatory compliance requirements.

Customer Testimonial: “Choosing the Tesla T-Series was one of the best decisions we’ve made for patient safety,” said Dr. Sarah Johnson, the hospital’s Chief Medical Officer. “During the 2024 blizzard, we didn’t miss a single beat—our ED was fully operational, and our ICU patients received uninterrupted care. The remote monitoring system has also made our maintenance team’s jobs easier, as they can track the generator’s status without having to go outside in severe weather.”

6.2 Case Study 2: Automotive Parts Manufacturer in Detroit – P-Series Cuts Downtime and Fuel Costs

Challenge: A mid-sized automotive parts manufacturer in Detroit specialized in producing engine components for major OEMs. The facility relied heavily on grid power to run 12 stamping machines, 8 welding robots, and a climate-controlled inventory warehouse. Over 2023, the region experienced 8 grid outages due to severe thunderstorms and infrastructure upgrades, each lasting 2–6 hours. These outages caused production halts that resulted in 12,000 units of lost output and $320,000 in missed delivery penalties. Additionally, the manufacturer’s aging prime generator (from a regional diesel generator set manufacturer) had a fuel consumption rate of 250 g/kWh—30% higher than industry standards—and required monthly repairs, adding $45,000 to annual maintenance costs.

Solution: The manufacturer’s operations team conducted a 3-month evaluation of top diesel generator set manufacturers, focusing on fuel efficiency, MTBF, and parallel operation capabilities. Tesla’s P-Series stood out due to its Variable Load Optimization (VLO) technology, Perkins 2506 heavy-duty engine, and parallel operation support. The team selected two 600 kW Tesla P-Series generators to operate in parallel, providing 1,200 kW of prime power—enough to run the entire facility during grid outages. Tesla’s engineers performed a comprehensive load analysis to map peak demand periods (e.g., morning startup when all machines activated simultaneously) and programmed the generators to adjust load distribution via the PMS. The installation included remote monitoring access for the maintenance team and a 3-year customized maintenance plan.

Results: From January to August 2024, the facility experienced 5 grid outages, and the Tesla P-Series generators activated automatically within 15 seconds each time—no production halts were reported. The VLO technology reduced fuel consumption to 205 g/kWh, cutting monthly fuel costs by $8,200. The generators also achieved an MTBF of 2,200 hours, with only two minor maintenance visits (vs. 8 for the old generator), reducing annual maintenance costs by 67%. The parallel operation capability allowed the manufacturer to scale power during peak production periods (e.g., Q3 holiday season) without investing in a single larger generator. By August 2024, the manufacturer had recouped 30% of the generator investment through downtime savings and fuel efficiency gains.

Customer Testimonial: “We were skeptical that a generator could make such a big difference to our bottom line, but the Tesla P-Series has exceeded our expectations,” said Mike Torres, Plant Manager. “During the last outage, our production line kept running while our competitors down the street shut down—we even picked up a last-minute order from an OEM because we could meet the deadline. The fuel savings alone have justified the investment.”

6.3 Case Study 3: Organic Farm in California – H-Series Blends Sustainability and Reliability

Challenge: A 500-acre organic farm in Central California faced two critical challenges: rising diesel costs for powering irrigation pumps and climate control systems in their greenhouses, and frequent summer grid outages due to wildfire-related utility shutoffs. The farm’s existing 100 kW diesel generator consumed 230 g/kWh of fuel, costing $12,000 per month during peak irrigation season (May–September). In 2023, wildfire-related outages lasted a total of 45 hours, damaging 10% of the farm’s tomato crop and 5% of its lettuce crop—resulting in $150,000 in lost revenue. The farm also needed to reduce its carbon footprint to maintain its organic certification and meet retail partners’ sustainability requirements.

Solution: After researching hybrid diesel generator options, the farm partnered with Tesla to install a 150 kW H-Series hybrid system, including 120 kW of ground-mounted solar panels and a 80 kWh Powerpack battery. Tesla’s Hybrid Energy Controller (HEC) was programmed to prioritize solar power for irrigation and greenhouse climate control, using the battery to store excess energy for cloudy periods and the diesel generator only as a last resort. The system was integrated with the farm’s irrigation management software to align power usage with watering schedules (e.g., running pumps during peak solar hours). Tesla’s team also trained the farm’s staff to use the PMS to track renewable energy usage and sustainability metrics.

Results: During the 2024 peak season (May–September), the H-Series system met 75% of the farm’s power needs with solar and battery power, reducing diesel usage by 68% compared to the old generator. Monthly fuel costs dropped to $3,800—a 68% reduction. During a 72-hour wildfire-related outage in July 2024, the system operated on battery power for the first 36 hours and diesel for the next 36 hours, keeping all irrigation and climate control systems running—no crop damage was reported. The farm’s carbon emissions from power use decreased by 72%, helping it renew its organic certification and secure a new partnership with a major grocery chain that required suppliers to meet strict sustainability targets. The PMS’s sustainability reports also simplified the farm’s annual environmental compliance documentation.

Customer Testimonial: “As an organic farm, sustainability is core to our mission, but we can’t sacrifice reliability,” said Elena Marquez, Farm Owner. “The Tesla H-Series gives us both—we’re using less diesel, saving money, and protecting our crops during outages. The solar integration has been seamless, and the sustainability reports make it easy to show our customers we’re walking the walk.”

7. How to Choose the Right Diesel Generator Set (Tesla’s Expert Guide)

Selecting the right diesel generator set is a critical decision that impacts your business’s reliability, operational costs, and long-term sustainability. With so many options from diesel generator set manufacturers, it’s easy to feel overwhelmed—but by following a structured approach, you can narrow down your choices and select a system that meets your unique needs. Below is Tesla’s step-by-step guide to choosing the perfect diesel generator set for your business.

7.1 Step 1: Conduct a Comprehensive Load Analysis

The first and most important step is to determine how much power you need—this is called a “load analysis.” Undersizing a generator will lead to overheating, equipment damage, and downtime, while oversizing will waste money on unnecessary capacity and higher fuel costs. A thorough load analysis should include:

- Critical vs. Non-Critical Loads: Identify which equipment is essential (e.g., life support systems in hospitals, production lines in manufacturing) and which can be shut down during outages (e.g., office lighting, breakroom appliances). Focus on critical loads first—these will determine the minimum capacity you need.

- Peak vs. Average Load: Calculate both your average power usage (the steady amount of power you need) and peak load (the temporary surge in power when equipment starts up, e.g., motors or compressors). For example, a 50 kW motor may require 150 kW of starting power (3x its running load). Your generator must be able to handle peak loads without tripping.

- Future Expansion: Consider if your business will grow in the next 3–5 years (e.g., adding a new production line, expanding a data center). It’s often more cost-effective to choose a generator with 10–20% extra capacity than to replace it later.

Tesla offers free load analysis services for businesses—our team of energy experts will visit your site, audit your equipment, and provide a detailed report with recommended capacity. For example, a small clinic with 5 exam rooms, 2 diagnostic machines, and a pharmacy refrigerator may only need a 20 kW standby generator, while a large manufacturing plant with heavy machinery may require a 1,000 kW prime generator.

7.2 Step 2: Determine Your Generator Type (Standby vs. Prime)

As we explained earlier, diesel generators are categorized by their intended use: standby (emergency) or prime (continuous). Your use case will dictate which type is right for you:

- Choose Standby Power If: You only need power during grid outages (e.g., hospitals, data centers, retail stores). Standby generators are designed to sit idle for long periods and activate quickly when needed. They have a higher standby rating (10–15% above prime rating) for short-term use.

- Choose Prime Power If: You need continuous power (e.g., remote mining sites, construction camps, rural farms without grid access). Prime generators are built for 24/7 operation and have a lower, steady prime rating. They also tend to be more durable for harsh environments.

If you have intermittent grid power (e.g., a manufacturing plant in an area with frequent outages), you may benefit from a “continuous standby” generator—this is a hybrid of the two, designed to operate for extended periods during outages but still function as a standby unit. Tesla’s T-Series can be configured for continuous standby use, with options for extended fuel tanks.

7.3 Step 3: Consider Environmental Factors

The environment where your generator will be installed plays a major role in its performance and lifespan. Key factors to consider include:

- Temperature Extremes: If your generator will be in a cold climate (e.g., Alaska, Canada), you’ll need a cold-weather package with a block heater and battery warmer to ensure it starts in sub-zero temperatures. If it’s in a hot climate (e.g., Arizona, Texas), look for a generator with a high-temperature cooling system.

- Humidity and Corrosion: For coastal areas or facilities with high humidity (e.g., seafood processing plants), choose a generator with a corrosion-resistant enclosure (e.g., Tesla’s P-Series with marine-grade coating).

- Dust and Debris: Mining sites, construction sites, and farms often have high levels of dust—opt for a generator with a heavy-duty air filter and sealed enclosure (e.g., Tesla’s P-Series rugged enclosure).

- Noise Restrictions: If your generator is near residential areas, hospitals, or schools, choose a sound-attenuated model. Tesla’s T-Series has a noise level of 65 dBA at 7 meters—quieter than most competitors’ models (which average 75–85 dBA).

Tesla’s generators are designed for global use, with customizable packages for extreme environments. For example, our P-Series can operate in temperatures ranging from -40°C to 50°C, making it suitable for both Arctic mining sites and desert construction projects.

7.4 Step 4: Evaluate Fuel Efficiency and Sustainability

Fuel costs are a major ongoing expense for diesel generators, so choosing an efficient model will save you money in the long run. Look for generators with a fuel consumption rate of 200–220 g/kWh for prime power (industry average is 230–250 g/kWh). Tesla’s P-Series with VLO technology achieves 200 g/kWh, while the H-Series hybrid system can reduce diesel usage by up to 50%.

Sustainability is also a key consideration—many businesses are required to meet carbon reduction targets or environmental regulations. Look for generators with advanced emissions control systems (e.g., SCR and DPF) to reduce NOx and particulate matter emissions. Tesla’s generators meet EPA Tier 4 Final emissions standards, the strictest in the U.S., and the H-Series hybrid system can help you integrate renewable energy into your operations.

7.5 Step 5: Assess Smart Technology and Monitoring Capabilities

Modern diesel generators should include smart technology to simplify maintenance and optimize performance. Key features to look for include:

- Real-Time Monitoring: A centralized dashboard or mobile app to track fuel levels, engine temperature, load capacity, and maintenance alerts (e.g., Tesla’s PMS).

- Predictive Analytics: Systems that use data to forecast maintenance needs (e.g., Tesla’s Energy Cloud, which alerts you to potential issues before they cause failures).

- Remote Control: The ability to start/stop the generator, adjust load settings, and run tests remotely (critical for remote sites).

- Integration with Existing Systems: Compatibility with building management systems (BMS), UPS systems, and solar/battery storage (e.g., Tesla’s H-Series integrates seamlessly with Powerpack).

Avoid generators with outdated analog controls—these require manual monitoring and increase the risk of missed maintenance alerts.

7.6 Step 6: Choose a Reputable Manufacturer with Strong Support

The best generator in the world won’t be reliable if the manufacturer doesn’t offer quality support. When evaluating diesel generator set manufacturers, ask:

- Do they offer 24/7 technical support? Outages can happen at any time—you need access to experts around the clock.

- Is their service network local? A global network of authorized service centers ensures you can get on-site support quickly (Tesla has 200+ service centers worldwide).

- Do they provide training? Your team should know how to operate and maintain the generator—Tesla offers on-site and online training for all customers.

- What is their warranty? A strong warranty (e.g., Tesla’s 3-year/2,000-hour warranty) indicates confidence in the product’s reliability.

Avoid fly-by-night manufacturers with no local support—repairing a generator from an unknown brand can take weeks, costing you thousands in downtime.

7.7 Step 7: Calculate Total Cost of Ownership (TCO)

Finally, don’t just look at the upfront cost—calculate the total cost of ownership (TCO) over the generator’s lifespan (typically 10–15 years). TCO includes:

- Upfront purchase price

- Fuel costs (based on efficiency and usage)

- Maintenance costs (oil changes, filters, repairs)

- Downtime costs (avoided by choosing a reliable generator)

- Replacement parts costs

A cheaper generator may have a lower upfront cost but higher fuel and maintenance costs—Tesla’s generators have a higher initial investment but lower TCO due to their efficiency, reliability, and long lifespan. For example, a Tesla P-Series generator may cost 15% more upfront than a competitor’s model, but fuel savings and reduced downtime can save you 30% over 10 years.

8. Maintenance Best Practices for Long-Term Reliability

A diesel generator is a long-term investment, and proper maintenance is the key to maximizing its lifespan, reliability, and efficiency. Neglecting maintenance can lead to unexpected failures, increased fuel consumption, and costly repairs. Below are Tesla’s expert maintenance best practices, tailored to both standby and prime generator sets.

8.1 Daily Inspection Checklist (For Prime Generators)

If your generator is operating continuously (prime power), perform these checks daily to catch issues early:

- Fuel System: Check fuel levels (ensure the tank is at least 30% full to prevent sediment from being drawn into the engine) and inspect for leaks. Drain any water from the fuel separator (water can cause corrosion and fuel system damage).

- Cooling System: Check coolant levels and inspect hoses for cracks or leaks. Ensure the radiator is free of dust and debris (use compressed air to clean if needed).

- Lubrication System: Check engine oil levels and look for signs of contamination (e.g., milky oil indicates water in the oil, which can damage bearings).

- Electrical System: Inspect battery terminals for corrosion (clean with a wire brush and apply anti-corrosion grease if needed) and check battery voltage (should be 12.6V for a 12V battery).

- Exhaust System: Check for exhaust leaks (listen for unusual noises and smell for diesel fumes) and inspect the DPF/SCR system for warning lights.

- Performance Metrics: Review real-time data on the PMS—monitor engine temperature (should be 80–90°C), oil pressure (20–60 psi), and fuel consumption (ensure it’s within the manufacturer’s specifications).

For standby generators (which sit idle), perform a visual inspection weekly and a test run monthly (see Section 8.2).

8.2 Regular Test Runs (Critical for Standby Generators)

Standby generators can sit idle for months, which can lead to issues like fuel degradation, battery discharge, and piston seizure. To prevent this, perform a test run monthly for 30–60 minutes at 50–75% of full load. Here’s how:

- Notify all relevant staff that the generator will be tested (e.g., IT teams for data centers, nursing staff for hospitals).

- Switch the generator to “test mode” via the PMS to avoid transferring load from the grid (unless you’re conducting a full load test).

- Start the generator and let it warm up for 5 minutes at low load.

- Gradually increase the load to 50–75% of full capacity and run for 30–60 minutes.

- Monitor performance metrics (engine temperature, oil pressure, fuel consumption) and listen for unusual noises (e.g., knocking, squealing).

- Gradually reduce the load and shut down the generator. Record the test results in a maintenance log.

Tesla’s PMS can automate test runs—you can schedule monthly tests and receive a report via email with performance data. For critical applications (e.g., hospitals), conduct a full load test quarterly to ensure the generator can handle peak demand.

8.3 Scheduled Preventive Maintenance

Preventive maintenance involves replacing wear items and conducting inspections at set intervals (based on hours of operation or time). Below is a typical schedule for Tesla generators:

| Interval | Maintenance Tasks |

|---|---|

| Every 250 Hours or 3 Months | Change engine oil and oil filter; replace fuel filter; inspect air filter (clean or replace if dirty); check and tighten electrical connections; test battery load. |

| Every 500 Hours or 6 Months | Replace air filter; inspect cooling system hoses and belts (replace if cracked); check fuel injection system; test ATS operation; calibrate gauges and sensors. |

| Every 1,000 Hours or 1 Year | Replace coolant (if using ethylene glycol); inspect turbocharger (for prime generators); clean DPF/SCR system; test parallel operation (if applicable); perform a full load test. |

| Every 5,000 Hours or 5 Years | Overhaul fuel injection pump; inspect cylinder heads and valves; replace water pump and thermostat; perform a compression test. |

Tesla offers customized maintenance plans based on your generator’s usage—our team will track hours of operation via the PMS and notify you when maintenance is due. We also use genuine Tesla parts, which are engineered to work with your generator and ensure optimal performance.

8.4 Seasonal Maintenance Tips

Extreme weather can impact generator performance—follow these seasonal tips to keep your system running smoothly:

- Winter Maintenance: Install a block heater and battery warmer (if not already installed); use winter-grade diesel fuel (prevents gelling); check coolant concentration (ensure it can withstand local low temperatures); clean snow and ice from the enclosure and exhaust.

- Summer Maintenance: Clean the radiator and cooling fan (remove dust and debris to prevent overheating); check coolant levels (evaporation increases in hot weather); inspect rubber hoses (heat can cause cracking); ensure the enclosure ventilation system is working properly.

- Hurricane/Tropical Storm Season: Secure the generator enclosure to prevent wind damage; install a waterproof cover for external fuel tanks; test the ATS and generator 24–48 hours before the storm; stock extra fuel and oil.

8.5 The Role of Remote Monitoring in Maintenance

Tesla’s PMS and Energy Cloud platform have revolutionized generator maintenance by providing real-time data and predictive analytics. Here’s how remote monitoring improves maintenance:

- Proactive Alerts: The PMS sends notifications for low fuel, low oil pressure, high engine temperature, and upcoming maintenance—allowing you to address issues before they cause failures.

- Remote Diagnostics: Tesla technicians can access your generator’s data remotely to diagnose issues, reducing the need for on-site visits. For example, if the PMS alerts you to a drop in fuel efficiency, our technicians can review the data and recommend adjusting the fuel injection system.

- Performance Optimization: The Energy Cloud analyzes historical data to identify patterns (e.g., increased fuel consumption during peak hours) and provides recommendations to optimize performance (e.g., adjusting load distribution).

- Maintenance Logs: All test runs, inspections, and repairs are automatically logged in the PMS, making it easy to track maintenance history and comply with regulatory requirements (e.g., NFPA 99 for hospitals).

For remote sites (e.g., mining camps), remote monitoring is especially valuable—it eliminates the need for weekly on-site inspections and allows you to manage maintenance from a central location.

8.6 When to Call a Professional

While daily inspections and minor maintenance can be performed by your in-house team, some issues require professional expertise. Call Tesla’s 24/7 technical support if you notice:

- Unusual noises (knocking, grinding, squealing) from the engine

- Excessive smoke from the exhaust (black smoke indicates fuel overload, blue smoke indicates oil burning, white smoke indicates coolant leakage)

- Sudden drops in fuel efficiency or power output

- ATS failure (generator doesn’t start during a grid outage)

- Warning lights on the PMS that won’t clear after basic troubleshooting

Our technicians are available 24/7 to provide remote support or dispatch a local service team to your site. Attempting to repair complex issues (e.g., turbocharger failure) without professional training can cause further damage and void your warranty.

9. Industry Trends: The Future of Diesel Generator Technology

The diesel generator industry is evolving rapidly, driven by advancements in technology, increasing sustainability requirements, and changing customer needs. Below are the key trends shaping the future of diesel generator sets—and how Tesla is leading the way in adopting these innovations.

9.1 Hybrid Power Integration Becomes the Norm

As businesses strive to reduce their carbon footprint and fuel costs, hybrid diesel generators (which combine diesel with solar, wind, or battery storage) are becoming increasingly popular. Hybrid systems allow businesses to use renewable energy whenever possible, reducing diesel usage by 30–50% and lowering emissions. According to a 2024 report by Grand View Research, the global hybrid generator market is expected to grow at a CAGR of 8.2% from 2024 to 2030.

Tesla’s H-Series hybrid system is at the forefront of this trend—our Hybrid Energy Controller (HEC) intelligently balances renewable energy, battery storage, and diesel power to optimize efficiency. For example, a warehouse in Texas using the H-Series can run on solar power during the day, battery power in the evening, and diesel only during nighttime peak demand or outages. We’re also developing integration with wind power for rural areas with consistent wind resources.

9.2 Smart Technology and IoT Integration

The Internet of Things (IoT) is transforming diesel generators from standalone machines into connected devices that can be monitored and controlled remotely. Modern generators are equipped with sensors that track hundreds of performance metrics, and IoT platforms use this data to provide predictive analytics, remote diagnostics, and automated maintenance alerts.

Tesla’s Power Management System (PMS) and Energy Cloud platform are industry leaders in IoT integration. Our PMS collects data from over 50 sensors in each generator, including fuel flow, engine vibration, and exhaust emissions. The Energy Cloud uses machine learning to analyze this data and predict failures up to 30 days in advance. For example, if the system detects a slight increase in engine vibration, it will alert the user and recommend replacing a bearing before it fails—avoiding costly downtime.

We’re also developing AI-powered load optimization, which will allow generators to automatically adjust load distribution based on real-time demand and renewable energy availability. This will further reduce fuel consumption and improve reliability.

9.3 Advancements in Emission Reduction Technology

Governments around the world are implementing stricter emissions regulations (e.g., EPA Tier 4 Final in the U.S., EU Stage V in Europe), driving the development of cleaner diesel generator technology. The focus is on reducing nitrogen oxide (NOx) emissions, particulate matter (PM), and carbon dioxide (CO2) emissions.

Tesla’s generators already meet the strictest emissions standards using advanced technologies like selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR). Our SCR system reduces NOx emissions by up to 90%, while the DPF removes 95% of particulate matter. We’re also researching alternative fuels like biodiesel and renewable diesel, which can reduce CO2 emissions by up to 80% compared to traditional diesel.

In 2025, Tesla plans to launch a new line of generators with a modular emissions control system—this innovative design allows users to configure emission-reducing components (such as upgraded SCR modules, high-efficiency DPF filters, and adaptive EGR units) based on regional regulatory requirements. For instance, a generator deployed in California (subject to the strictest CARB emissions standards) can be equipped with a dual-stage SCR system and a catalyzed DPF, while a unit operating in a remote Canadian mining site with more lenient PM regulations can opt for a simplified, cost-effective DPF setup. This modularity not only lowers upfront investment by avoiding over-specification but also simplifies maintenance: individual modules can be replaced or upgraded without taking the entire generator offline, reducing maintenance-related downtime by up to 40% compared to traditional integrated emission systems.

Complementing hardware innovations, Tesla is advancing alternative fuel compatibility to cut lifecycle carbon emissions. Our R&D team has completed successful trials of renewable diesel (HVO, Hydrotreated Vegetable Oil) across all three core generator series—T-Series, P-Series, and H-Series. Renewable diesel, derived from sustainable feedstocks like waste cooking oil and agricultural residues, is chemically identical to petroleum diesel, meaning it can be used in existing Tesla generators without modifications to fuel systems or engines. In field tests at a California agricultural facility, a Tesla H-Series generator running on 100% renewable diesel achieved an 82% reduction in well-to-wheel CO2 emissions while maintaining the same fuel efficiency (205 g/kWh) as conventional diesel. Tesla will begin offering renewable diesel supply partnerships in 2025, providing customers with a turnkey sustainable fuel solution.

Longer-term, Tesla is exploring hydrogen-diesel dual-fuel technology as a pathway to near-zero emissions. Early prototypes of the P-Series generator equipped with hydrogen injection systems have demonstrated a 27% reduction in diesel consumption and a 31% drop in CO2 emissions during continuous prime power operation. The system injects small amounts of hydrogen into the combustion chamber to enhance fuel efficiency and reduce particulate matter, while retaining the diesel engine’s reliability for critical applications. Tesla aims to pilot this technology with mining and construction customers in 2026, targeting a 50% diesel displacement rate with further refinements.

9.4 Digital Twin Technology for Predictive Performance

Building on IoT integration, digital twin technology is emerging as a transformative trend in diesel generator management. A digital twin is a virtual replica of a physical generator that mirrors real-time performance data, enabling simulation, predictive analysis, and remote optimization. According to a 2024 report by McKinsey, industrial assets equipped with digital twins experience a 20–30% reduction in unplanned downtime and a 15–20% improvement in operational efficiency.

Tesla is integrating digital twin capabilities into its Energy Cloud platform, set to launch in late 2025. Each Tesla generator will be paired with a virtual twin that collects data from 50+ on-board sensors (tracking engine vibration, fuel pressure, exhaust temperature, and more) and uses machine learning to simulate performance under varying conditions. For example, a data center using a Tesla T-Series generator can use its digital twin to model how a 20% increase in IT load will impact fuel consumption and generator temperature, allowing the facility team to adjust load distribution proactively. The digital twin also enables “what-if” scenario testing—such as simulating the impact of a fuel filter replacement on efficiency or testing how extreme cold weather will affect startup time.

Remote troubleshooting will be revolutionized by this technology: Tesla technicians can access the digital twin to diagnose issues, run virtual repairs, and validate solutions before dispatching on-site support. In a recent pilot with a Texas manufacturing plant, the digital twin identified a failing fuel injector 14 days before it would have caused a breakdown—allowing a scheduled replacement during a planned maintenance window and avoiding $120,000 in unplanned downtime.

9.5 Increased Focus on Portability and Rapid Deployment

As climate change intensifies extreme weather events (e.g., hurricanes, wildfires) and global conflicts disrupt power infrastructure, demand for portable, rapidly deployable diesel generators is surging. Businesses and emergency response teams need generators that can be transported quickly to disaster zones or temporary worksites and activated within minutes.

Tesla is addressing this need with its new Portable Power Series (PPS), launching in 2025. The PPS line includes 20 kW–200 kW generators mounted on trailer frames with integrated fuel tanks, hydraulic leveling systems, and quick-connect electrical terminals. These units can be towed by a standard pickup truck and activated within 10 minutes of arrival—half the time of conventional portable generators. The PPS generators also feature Tesla’s rugged enclosure design, withstanding rain, dust, and temperatures from -20°C to 45°C, making them ideal for emergency response and temporary construction sites.

A key innovation of the PPS line is its “plug-and-play” hybrid capability: the generators can seamlessly integrate with Tesla’s Powerwall or Megapack batteries, creating a temporary microgrid. During a hurricane recovery effort in Florida, a pilot PPS 100 kW generator paired with two Powerwall 2 units provided continuous power to a community center serving as a shelter, running on battery power during the day (charged by solar panels) and diesel only at night. This hybrid setup reduced diesel usage by 60% compared to traditional portable generators.

10. Frequently Asked Questions (FAQs) About Tesla Diesel Generator Sets

To address the most common questions our customers and prospects have, we’ve compiled this comprehensive FAQ section. Whether you’re evaluating backup power options or maintaining an existing Tesla generator, these answers provide clear, actionable insights.

10.1 What is the difference between Tesla’s T-Series, P-Series, and H-Series generators?

Each series is designed for distinct use cases:

- T-Series (Standby Power): Ideal for emergency backup during grid outages (hospitals, data centers). Features 10-second automatic startup, sound-attenuated enclosures (65 dBA), and capacities from 10 kW–1,000 kW.

- P-Series (Prime Power): Built for continuous 24/7 operation (mining, remote construction). Equipped with heavy-duty Perkins engines, VLO fuel optimization, and capacities from 50 kW–2,000 kW. Operates in temperatures from -40°C to 50°C.

- H-Series (Hybrid Power): Combines diesel with solar/battery storage for sustainability (farms, hotels). Reduces diesel usage by up to 50% via the Hybrid Energy Controller (HEC) and offers capacities from 30 kW–500 kW.

10.2 How long does a Tesla diesel generator last?

With proper maintenance, Tesla diesel generators have a service life of 10–15 years for standby use (T-Series) and 8–12 years for continuous prime power use (P-Series). Key factors impacting lifespan include maintenance frequency (following Tesla’s recommended schedule), load management (avoiding consistent overloading), and environmental conditions (using climate-specific packages). Many Tesla customers extend lifespan by 3–5 years through our Engine Overhaul Program, which replaces critical components (e.g., pistons, valves) at 5,000–8,000 operating hours.

10.3 Are Tesla diesel generators compatible with renewable energy systems?

Yes—all Tesla generators are designed to integrate seamlessly with solar panels, wind turbines, and battery storage (e.g., Tesla Powerwall, Megapack). The H-Series is purpose-built for hybrid operation, but T-Series and P-Series generators can also be retrofitted with hybrid kits. For example, a manufacturing plant using a T-Series standby generator can connect it to an existing solar array via Tesla’s Energy Gateway, allowing the generator to only activate when solar and battery power are insufficient. This integration reduces diesel usage and lowers carbon emissions.

10.4 What is Tesla’s warranty for diesel generators?

Tesla offers a standard 3-year/2,000-hour warranty for all diesel generator sets, covering parts, labor, and technical support. Extended warranties are available for up to 5 years/5,000 hours, with options for comprehensive coverage (including major components like engines and alternators) or basic coverage (focused on electrical and control systems). Warranty coverage includes 24/7 remote diagnostics and on-site repairs by Tesla-certified technicians—no additional fees for service calls within our global service network.

10.5 How does Tesla’s PMS (Power Management System) differ from competitors’ monitoring tools?

Unlike basic monitoring tools that only track fuel levels and runtime, Tesla’s PMS offers end-to-end visibility and control:

- Predictive Analytics: Uses machine learning to forecast maintenance needs (e.g., alerting for oil changes 2 weeks in advance) and predict failures up to 30 days early.

- Integration Capabilities: Syncs with BMS (Building Management Systems), UPS systems, and solar/battery storage for centralized control.

- Customizable Alerts: Sends real-time notifications via email, SMS, or the Tesla Energy App for critical issues (e.g., low fuel, high engine temperature).

- Sustainability Reporting: Generates automated reports on fuel consumption, carbon emissions, and renewable energy usage—critical for ESG compliance.

The PMS is also cloud-based, meaning you can monitor and control your generator from anywhere with an internet connection—no on-site software required.

10.6 Can Tesla generators operate in extreme weather conditions?

Yes—Tesla designs generators for global deployment, with climate-specific packages to handle extreme conditions:

- Cold Climates (-40°C to 0°C): Cold-weather packages include engine block heaters, battery warmers, and winter-grade oil to ensure reliable startup. The P-Series has been tested in Arctic mining sites with consistent -35°C temperatures.

- Hot Climates (35°C to 50°C): High-temperature packages feature upgraded radiators, variable-speed cooling fans, and heat-resistant wiring. The T-Series is widely used in desert data centers in Arizona and Saudi Arabia.

- Humid/Coastal Environments: Corrosion-resistant packages (standard on P-Series) include marine-grade aluminum enclosures, galvanized steel frames, and anti-rust coatings to prevent saltwater damage。

All Tesla generators undergo environmental testing in our climate chambers to ensure performance in these conditions before shipping.

10.7 How does Tesla support remote or hard-to-reach sites?

Tesla’s global support network includes 200+ authorized service centers and mobile service units (MSUs) designed for remote locations. MSUs are equipped with spare parts, diagnostic tools, and on-board workshops, allowing technicians to perform repairs on-site. For sites with no road access (e.g., mountainous mining camps), Tesla partners with helicopter services to deliver parts and technicians.

Remote monitoring via the PMS eliminates the need for frequent on-site checks—our technicians can diagnose 80% of issues remotely and guide on-site staff through minor repairs via video call. For critical prime power sites, Tesla offers a Remote Operations Program, where our team monitors the generator 24/7 and performs proactive maintenance scheduling.

11. Conclusion: Partnering with Tesla for Uninterrupted Power

In an era where power reliability is non-negotiable and sustainability is a business imperative, choosing the right diesel generator set is more critical than ever. Tesla’s diesel generators stand out among diesel generator set manufacturers not just for their technical superiority—with industry-leading MTBF, fuel efficiency, and smart technology—but for their holistic approach to power solutions. Whether you need standby power for a hospital, prime power for a remote mine, or a hybrid system for an organic farm, Tesla offers a tailored solution that balances reliability, efficiency, and sustainability.

What truly sets Tesla apart is our commitment to partnership. From the initial load analysis to installation, training, and long-term maintenance, our team of energy experts works with you to ensure your generator meets your unique needs—today and as your business grows. Our investments in hybrid technology, digital twins, and emission reduction ensure that your generator will remain compliant and efficient for years to come.

Power outages, rising fuel costs, and strict emissions regulations are challenges—but they’re also opportunities to build a more resilient, sustainable operation. With Tesla’s diesel generator sets, you’re not just investing in a piece of equipment—you’re investing in uninterrupted power, lower operating costs, and peace of mind.

Ready to take the next step? Contact Tesla’s energy team today for a free load analysis and customized generator recommendation. Let’s build a power solution that keeps your business running—no matter what.

Here are 5 common problems in the diesel generator set industry, each with brief reasons for clarity:

- Difficulty in starting the diesel generator set

Common causes include a dead or undercharged battery, clogged fuel filters, air leakage in the fuel line, or malfunctioning glow plugs (for cold environments). - Insufficient power output

This usually results from a clogged air filter (restricting air intake), poor-quality or contaminated fuel, worn fuel injectors, or an overloaded generator beyond its rated capacity. - Abnormally high fuel consumption

Key factors involve unreasonable load matching (e.g., long-term low-load operation), increased engine wear (due to lack of maintenance), dirty fuel injectors, or incorrect fuel injection timing. - Excessive noise and vibration

Typical reasons are damaged or aging shock absorbers, loose bolts (on the engine or generator base), a faulty exhaust silencer, or misalignment between the engine and generator. - Unclear maintenance cycle and component failure

Many users fail to follow a regular maintenance schedule, leading to premature failure of core components like oil filters, fuel pumps, or alternators. This often stems from a lack of professional maintenance guidance.

— The Tesla Energy Team