When your manufacturing line goes dark at 2 AM, or a grid failure threatens to shut down your data center, you need backup power that actually works. Not equipment that sits idle for months and fails when you flip the switch. The stakes are high: downtime costs industrial facilities an average of $260,000 per hour according to industry data, and picking the wrong emergency power solutions can turn a temporary outage into a financial disaster.

That’s where China Yuchai diesel generator sets enter the conversation. You’ve probably heard the name—Yuchai has been manufacturing engines since 1951 and claims significant market share in China’s power generation sector. But what does that actually mean for your facility? Should you consider a Chinese manufacturer when established Western brands dominate the conversation at procurement meetings?

This isn’t a sales pitch. It’s a technical evaluation grounded in specifications, real-world performance data, and practical considerations that matter when you’re writing a purchase order. We’ll examine what sets Yuchai apart in the crowded industrial power backup systems market—from their engine technology and manufacturing scale to service networks and total cost of ownership. Whether you’re specifying equipment for a new construction project, replacing aging generators, or evaluating vendors for the first time, you’ll walk away with concrete criteria for your decision.

At Tesla Power, we’ve deployed Yuchai units across dozens of industrial installations, from pharmaceutical plants to telecommunications hubs. We’ve seen what works and what doesn’t. This article breaks down the technical reality behind the brand name.

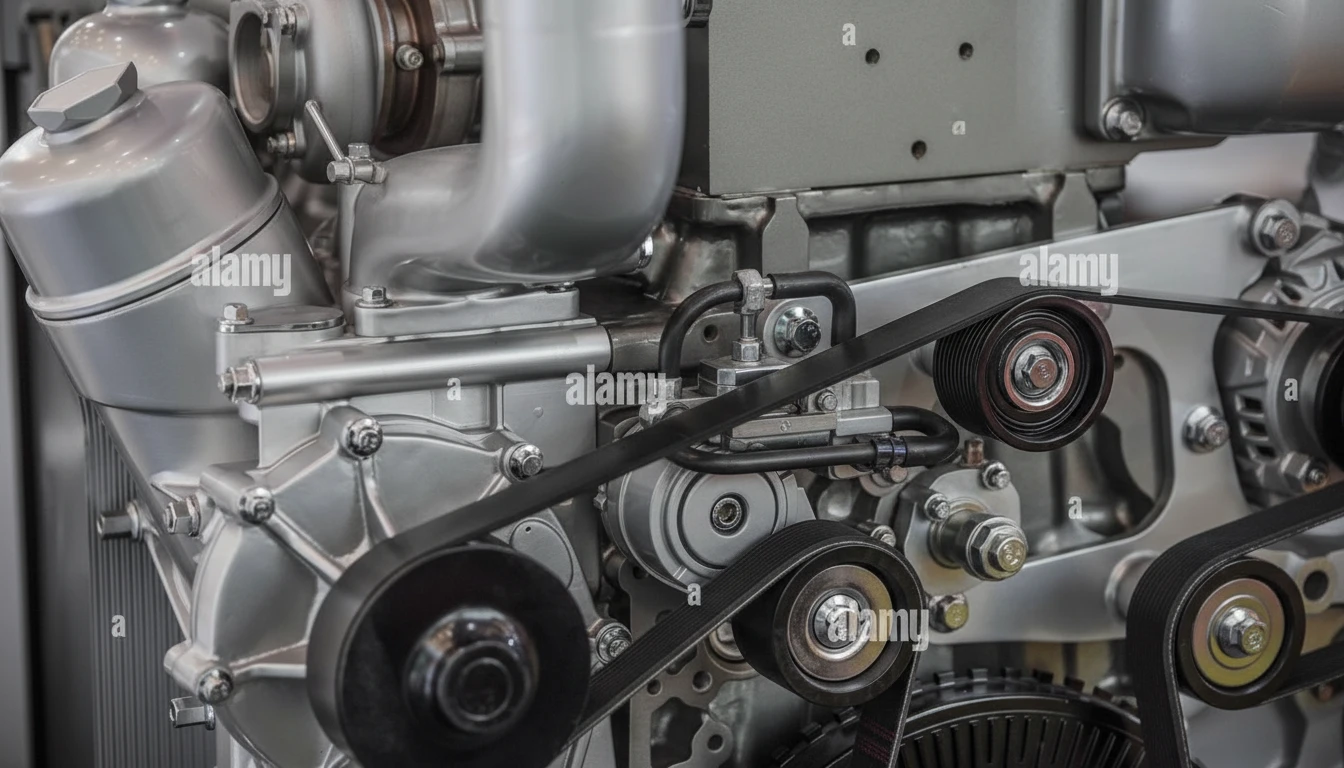

Figure 1: Modern Yuchai diesel generator installation in an industrial setting. These units provide reliable backup power for facilities where downtime costs can exceed $260,000 per hour, demonstrating the critical role of dependable power generation equipment in industrial operations.

Understanding Yuchai as a Manufacturer

Before you evaluate any generator set, you need to understand who’s building it. Yuchai isn’t some startup chasing the industrial power market—Guangxi Yuchai Machinery Group has operated since 1951 as a state-owned enterprise with more than 20 subsidiaries spanning engine manufacturing, supply chain logistics, and power systems. That’s over seven decades of accumulated engineering knowledge and production refinement.

The numbers tell part of the story. Yuchai employs roughly 13,000 workers across industrial bases in Guangxi, Guangdong, Jiangsu, Anhui, Hubei, Chongqing, and Liaoning. Annual sales hover around RMB 50 billion, and the company consistently ranks in China’s top engine manufacturers by sales volume. In 2024, the brand carried an assessed value of RMB 102.059 billion—recognition that comes from decades of market presence and customer relationships, not marketing budgets.

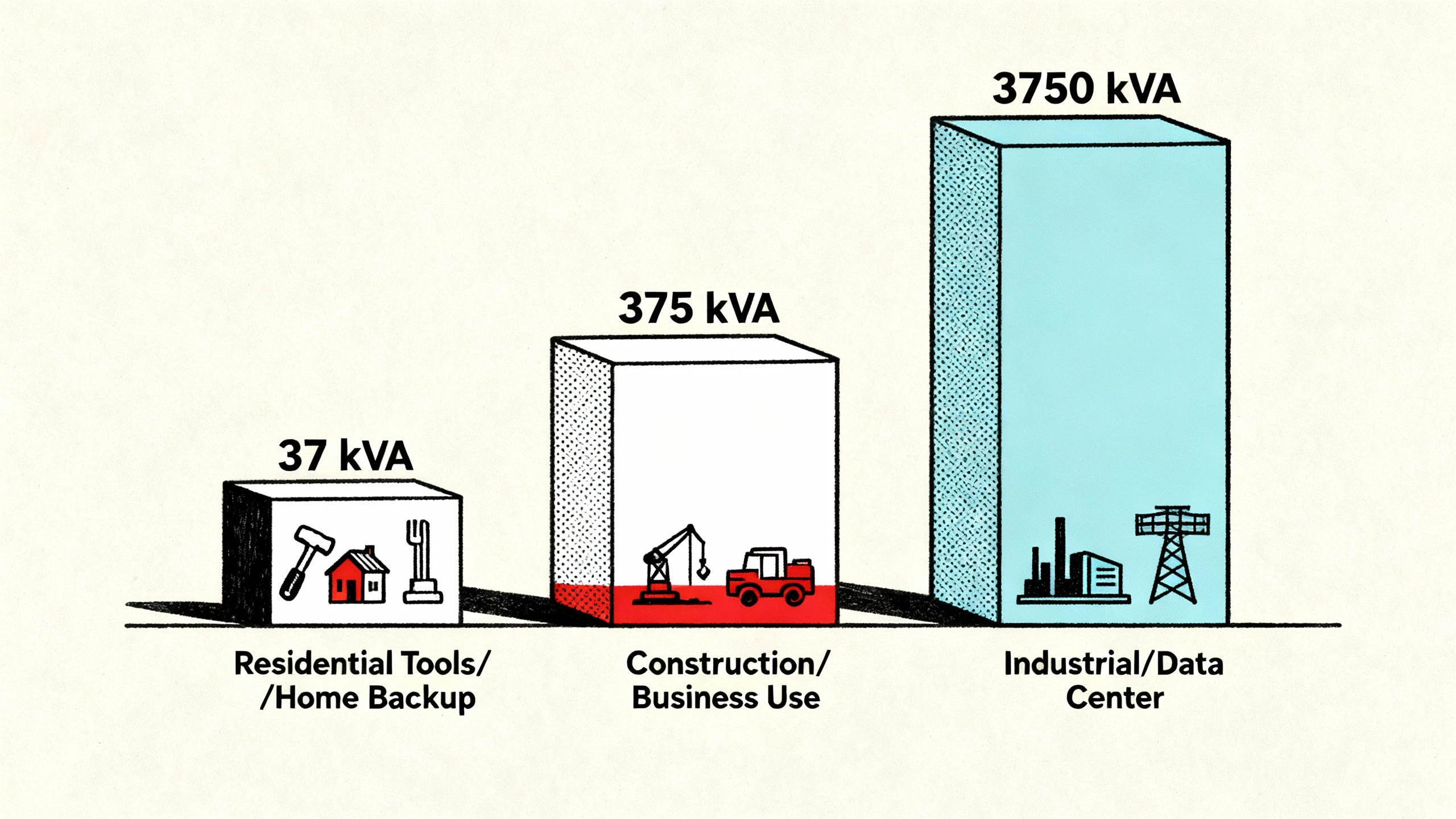

What matters more than revenue is production capacity and range. Yuchai manufactures diesel generator reliability solutions from 37.5 kVA all the way up to 3,750 kVA, covering everything from small construction sites to utility-scale installations. They’ve also localized MTU S4000 series engines through joint ventures, blending European design standards with Chinese manufacturing scale. When you see “Yuchai” on a nameplate, you’re looking at equipment from one of Asia’s largest dedicated power system manufacturers.

Global reach backs up domestic scale. Yuchai maintains offices and distribution in over 180 countries, with an after-sales network spanning 6,300+ domestic service stations and 1,500+ overseas service outlets. Compare that to niche manufacturers with limited parts availability outside their home markets. For commercial generator sets deployed internationally, parts logistics and service response times directly impact your total cost of ownership and operational uptime.

Technical Specifications That Matter

Specs on a datasheet mean nothing until you understand what they deliver in operation. Let’s cut through the marketing language and focus on Yuchai generator specifications that directly affect performance, efficiency, and reliability in real-world installations.

Power Range and Model Families

Yuchai’s generator portfolio divides into distinct families, each engineered for specific load profiles:

Small Capacity (YC4D Series: 37-63 kVA): The YC30GF and YC50GF models operate at 50 Hz with power factor 0.8, delivering 30-50 kW prime power. These units use 4-cylinder inline engines with 4.214L displacement—compact enough for mobile applications or small facilities but built with the same turbocharging and electronic fuel regulation you’ll find in larger units. Dimensions around 1,800 x 770 x 1,200 mm and weights under 850 kg make them field-deployable without heavy rigging equipment.

Mid-Range (YC12VTD Series: 800-1,500 kVA): Step up to the YC800GF through YC1200GF, and you’re working with 12-cylinder V-configuration engines displacing 39.2L. These models deliver 800-1,200 kW prime power with turbocharged and intercooled architecture. The Yuchai engine technology here includes high-pressure common rail (HPCR) fuel injection—the same system used in modern heavy-duty trucks to optimize combustion timing and reduce fuel consumption. Expect transient frequency deviation under +10%/-7% and voltage recovery within 3 seconds under load steps, performance characteristics that matter when sensitive equipment depends on stable power.

High-Output (YC16VC Series: 2,250-3,750 kVA): The flagship units like the YC1800GF to YC3000GF push 1,800-3,000 kW prime power from 16-cylinder V-engines with 105.56L displacement. These aren’t generators—they’re industrial power plants. Rated currents climb to 5,400 A, and units weigh up to 22,500 kg with footprints around 6,500 x 2,800 x 3,200 mm. Electronic unit pump (EUP) or HPCR fuel systems maintain steady-state frequency deviation under 0.5% and voltage deviation within ±1%, tight enough for telecommunications infrastructure and medical facilities that can’t tolerate power quality issues.

Engine Technology and Efficiency

What makes Yuchai competitive isn’t just displacement or cylinder count—it’s how the engines manage combustion and thermal loads:

Fuel Systems: High-pressure common rail injection operates at pressures exceeding 1,800 bar, atomizing diesel into microscopic droplets for complete combustion. This translates to measurable generator fuel efficiency: specific fuel consumption around 205 g/kWh at prime power and 75% load, rising only to 215 g/kWh at 50% load. Compare that to older mechanical injection systems burning 240+ g/kWh, and you’re looking at 15-20% fuel savings over a generator’s 20-year lifecycle.

Air Management: Turbocharging with intercooling isn’t optional on modern diesels—it’s required to meet emission standards and maintain power output at altitude or high ambient temperatures. Yuchai’s four-valve cylinder heads and centralized injector placement optimize air-fuel mixing, pulling more work from each combustion cycle while keeping exhaust temperatures manageable.

Emissions Compliance: Yuchai engines carry non-road Tier 2 and Tier 3 emission certifications under relevant standards. That matters if you’re operating in jurisdictions with strict air quality regulations or seeking LEED certification for new construction projects. It also indicates modern combustion engineering that tends to correlate with efficiency and reliability.

Figure 2: High-pressure common rail fuel injection and turbocharger technology in modern diesel engines. These precision-engineered components enable Yuchai generators to achieve 205 g/kWh fuel consumption rates, translating to 15-20% efficiency gains over older mechanical injection systems and significant lifecycle cost savings.

Applications Across Industries

China Yuchai diesel generator sets aren’t designed for one narrow use case—they’re engineered for the full spectrum of industrial and commercial power scenarios. Understanding where these units excel helps you evaluate fit for your specific requirements.

Industrial Manufacturing Facilities

Manufacturing operations can’t tolerate voltage sags or frequency instability. A momentary power dip shuts down CNC machines mid-cycle, corrupts PLC programming, or damages motor drives. Yuchai’s tight voltage regulation (±1% steady-state) and rapid load response (recovery within 3 seconds) make these units suitable for facilities running precision machinery, injection molding equipment, or automated assembly lines. The modular installation design and sound-attenuated enclosures available across the product line also address facility managers’ concerns about noise levels in multi-shift operations.

Commercial Buildings and Data Centers

Data centers and commercial high-rises need standby power applications that kick in automatically during grid failures and maintain clean power for IT infrastructure. Yuchai generator sets integrate with automatic transfer switches (ATS) and support remote monitoring through microprocessor-based control panels. Real-time parameter tracking—voltage, current, frequency, oil pressure, coolant temperature—enables facility managers to verify system readiness without manual inspection. For multi-tenant buildings, the ability to size generators from 37.5 kVA up to multi-megawatt configurations means you can match capacity precisely to building loads without over-specifying equipment.

Construction Sites and Remote Locations

Construction projects and remote work sites present unique challenges: dusty environments, temperature extremes, transportation constraints, and limited access to technical support. Smaller Yuchai units (YC4D and YC6 series) deliver field-proven reliability in these conditions. Heavy-duty air filtration protects engines from particulate ingestion, robust radiator designs handle high ambient temperatures, and weights under 1,000 kg for compact models enable transport without specialized rigging. At Tesla Power, we’ve seen these units operate continuously in desert construction sites and coastal industrial projects where salt air and sand would compromise lesser equipment.

Emergency Backup for Critical Infrastructure

Hospitals, telecommunications hubs, water treatment plants, and emergency services facilities need absolute reliability in their backup power generation equipment. Lives and essential services depend on generators that start immediately and run for extended periods. Yuchai’s extensive service network becomes critical here—if a fuel injector fails or a sensor malfunctions at 3 AM, you need parts available locally and technicians who know the equipment. The global distribution network with 1,500+ overseas service outlets directly addresses this operational reality.

Figure 3: Commercial facility with backup generator system providing emergency power. Yuchai generator sets serve diverse applications including manufacturing plants, data centers, construction sites, and critical infrastructure where power continuity is essential for operations and safety.

Key Advantages of Yuchai Generator Sets

Every manufacturer claims reliability and efficiency. What actually separates China Yuchai diesel generator sets from alternatives when you’re comparing proposals and evaluating total cost of ownership?

Fuel Efficiency and Operating Costs

Fuel represents the largest operational expense for any generator running extended hours. Yuchai’s specific fuel consumption figures—205 g/kWh at optimal load and 215 g/kWh at half load—translate directly to your operating budget. Run a 1,000 kW unit 500 hours annually (typical for backup installations with monthly testing), and that 15-20% efficiency advantage over older technology saves roughly 7,500-10,000 liters of diesel per year. At current fuel prices, that’s $7,500-$12,000 in annual savings—enough to recover a significant portion of your capital investment over the equipment’s 20-year lifespan.

The Yuchai engine technology behind these numbers isn’t magic—it’s engineering. High-pressure common rail injection optimizes combustion timing across the load range, and intelligent load sensing adjusts fuel delivery dynamically rather than running rich at all operating points. These systems have been proven in millions of heavy-duty trucks and industrial engines worldwide.

Reliability and Durability Features

Reliability starts with fundamentals: heavy-duty engine blocks designed for continuous operation, not intermittent use. Yuchai engines use mesh-reinforced V-blocks on larger models and wet-sleeve cylinder designs that simplify major overhauls when you eventually need them. Four-valve cylinder heads reduce thermal stress compared to two-valve designs, and oversize alternators with robust winding configurations handle starting surges without demagnetization.

Thermal management often determines whether a generator makes it through a multi-day power outage. Yuchai specs oversize radiators with efficient fan designs to maintain stable coolant temperatures even when ambient conditions spike. Advanced filtration systems—both for fuel and lubrication oil—protect injection components and bearings from contamination that causes 80% of premature diesel engine failures.

Modular construction philosophy means you can perform routine maintenance—oil changes, filter replacements, coolant system service—without specialized tooling or factory-trained technicians. That’s critical for installations in secondary markets where technical support infrastructure is limited.

Control Systems and Safety Features

Microprocessor-based controllers in modern Yuchai generator sets provide capabilities that were impossible a generation ago: real-time monitoring of dozens of parameters, automated load management to optimize efficiency, self-diagnostic routines that identify developing problems before they cause failures, and protective logic that shuts down engines safely when conditions exceed safe operating parameters.

Overheat protection, low oil pressure shutdown, overspeed governors, and emergency stop circuits are standard—not optional upgrades. For facilities with multiple generators, paralleling controls enable seamless load sharing and redundancy without manual intervention. Remote monitoring capabilities (via Modbus, CAN bus, or proprietary protocols) integrate with building management systems or SCADA infrastructure.

Service Network and Global Support

You can specify the perfect generator on paper, but if you can’t get parts or technical support when something breaks, you’ve bought an expensive paperweight. This is where Yuchai’s Yuchai service network becomes a competitive advantage rather than a specification line item.

With 6,300+ domestic service stations in China and 1,500+ international outlets, Yuchai maintains parts inventory and trained technicians in markets where niche brands rely on third-party distributors who may not stock components. The company operates 29 overseas marketing agencies and maintains a 24-hour global hotline for technical support—infrastructure that matters when a critical generator fails during a holiday weekend.

At Tesla Power, we’ve leveraged this network across client installations in Southeast Asia, Africa, and Latin America. Response times for parts requests average 24-48 hours in major markets, comparable to established Western brands but often at lower total parts costs due to local inventory rather than air freight from Europe or North America.

Figure 4: Yuchai’s comprehensive generator power range spans from compact 37.5 kVA units for small facilities to industrial-scale 3,750 kVA systems. This broad portfolio enables precise capacity matching for applications ranging from mobile construction equipment to utility-grade power plants.

Maintenance and Operational Considerations

Ownership costs extend far beyond the purchase order. Understanding maintenance requirements and operational characteristics determines whether a China Yuchai diesel generator set makes financial sense for your application.

Maintenance Requirements and Service Intervals

Yuchai engines follow ISO 8528 power definitions for Prime and Standby ratings, with corresponding maintenance schedules tied to operating hours and load profiles. Typical service intervals include oil and filter changes every 250-500 hours depending on operating conditions, fuel filter replacement every 500 hours, air filter service based on restriction indicator readings (typically 500-1,000 hours in clean environments), and coolant system inspection and fluid changes annually or every 2,000 hours.

These intervals align with industry standards—not shorter cycles that inflate service costs or longer intervals that risk reliability. The modular design philosophy extends to maintenance access: filters, oil drain points, and inspection ports are positioned for technician access without disassembling protective enclosures or major components.

For critical installations, establish a comprehensive preventive maintenance program including monthly load bank testing to verify full-load performance, quarterly battery and charging system checks, annual cooling system pressure tests and leak detection, and biannual governor calibration and control system verification. These procedures aren’t Yuchai-specific—they’re best practices for any standby generator regardless of brand.

Fuel Consumption and Operating Economics

Planning fuel storage and calculating lifecycle costs requires accurate consumption data. Yuchai publishes measured fuel consumption for representative models: a YC16VTD engine at 1,500 RPM running at prime power consumes approximately 205 g/kWh, with consumption rising to 215 g/kWh at 50% load. For practical planning, assume a 1,000 kW generator running at 75% load burns roughly 154 liters per hour (205 g/kWh × 750 kW ÷ diesel density ~0.85 kg/L).

Multiply by your expected annual operating hours—monthly testing plus anticipated grid outages—to size fuel storage. Include 10-15% margin for temperature variations and aging engine efficiency decline. For extended-run applications (continuous prime power rather than standby), fuel costs dominate total cost of ownership: a generator running 4,000 hours annually at $1.20/liter fuel price costs roughly $740,000 in fuel over 20 years, dwarfing the initial equipment purchase.

This is where efficiency matters. That 15% fuel consumption advantage over older technology saves $110,000+ over equipment lifetime—real money that flows directly to your operating budget bottom line.

Parts Availability and Supply Chain

Component availability determines whether a generator returns to service in hours or sits idle for weeks. Yuchai’s manufacturing scale and global distribution network maintain inventory for high-wear items: fuel injection components, filters, gaskets and seals, electronic sensors and controllers, alternator components, and cooling system parts.

Work with distributors like Tesla Power who stock commonly-needed parts locally and maintain established relationships with regional Yuchai service centers. For critical installations, consider maintaining on-site spares for long-lead items specific to your generator model: injectors, electronic control modules, starter motors, and alternator assemblies.

Recommended consumables follow GB (Chinese national) and international standards: diesel fuel meeting GB 252-2015 seasonal specifications (0# or 10# in summer; 0#, -10#, -20#, or -35# in winter depending on climate), lubricating oil 15W-40 (summer) or 10W-30 (winter) meeting minimum CH-4 specification per GB 11122-2006, and coolant meeting OEM specifications with appropriate freeze protection and corrosion inhibitors.

These aren’t exotic specifications—any industrial supplier can source appropriate fluids. That’s by design: Yuchai engineers for global serviceability rather than proprietary lock-in.

Figure 5: Routine maintenance is critical for generator reliability and longevity. Yuchai’s modular design philosophy enables straightforward service access for oil changes, filter replacements, and inspections without specialized tooling, supported by 6,300+ domestic and 1,500+ international service outlets for parts and technical support.

Conclusion

China Yuchai diesel generator sets aren’t the right choice for every application, but they represent a compelling value proposition when your priorities align with their strengths: proven engine technology at competitive pricing, extensive global service infrastructure, comprehensive power range from small mobile units to multi-megawatt installations, and measurable fuel efficiency advantages that reduce lifecycle operating costs.

The decision framework comes down to matching technical requirements with operational realities. If your facility needs tight voltage regulation for sensitive equipment, verify that Yuchai’s ±1% steady-state specification meets your needs. If you’re operating in remote markets, confirm local service availability through distributors before committing. If fuel costs dominate your budget calculations, run the numbers on specific consumption data rather than relying on marketing claims.

Yuchai’s seven decades of manufacturing experience and position as one of Asia’s largest engine producers provide reassurance that the company will remain viable through your equipment’s 20-year service life. That matters for parts availability and engineering support when you’re planning major overhauls a decade from now.

For procurement teams evaluating proposals, include Yuchai in your competitive bid process. Request detailed specifications, fuel consumption curves, maintenance schedules, and local service commitments in writing. Compare total cost of ownership—not just capital cost—across competing proposals. Visit reference installations if possible to see units operating in conditions similar to yours.

If you’re ready to evaluate Yuchai generator sets for your specific application, Tesla Power maintains technical specialists who can review your load profiles, duty cycles, and site conditions to recommend appropriate models and configurations. We handle installations across industrial, commercial, and institutional sectors with full commissioning and ongoing maintenance support.

Frequently Asked Questions

Q: How does Yuchai compare to established Western brands like Cummins or Caterpillar in terms of reliability?

Yuchai engines meet ISO 8528 standards and carry non-road Tier 2/3 emission certifications, indicating comparable engineering fundamentals. The reliability question often comes down to specific installation quality, maintenance practices, and operating conditions rather than brand alone. Yuchai’s advantage lies in competitive pricing without sacrificing core performance specifications like voltage regulation (±1%) or transient response (3-second recovery). For buyers prioritizing cost-effectiveness with proven technology, Yuchai offers a middle path between premium Western brands and lower-tier Asian manufacturers.

Q: What kind of warranty and after-sales support can I expect with a Yuchai generator set?

Standard warranties typically cover 12-24 months or 1,000-2,000 operating hours, though specific terms vary by distributor and application. The critical factor is local service availability: Yuchai maintains 6,300+ service stations domestically and 1,500+ internationally, with 24-hour technical support hotlines. Work with established distributors who stock parts locally and maintain factory-trained technicians. Request written service level agreements specifying response times and parts availability commitments before purchasing.

Q: Are Yuchai generator sets suitable for prime power applications, or only standby use?

Yuchai manufactures both prime and standby-rated units across their product line. Prime power models are designed for continuous or extended operation (up to 70% average load over 24 hours per ISO 8528), while standby units handle emergency backup with limited annual operating hours. Check the specific model rating on your quote—prime-rated generators use heavier-duty components and cost more, but they’re required for applications like remote construction sites or facilities without grid connections. Using a standby-rated unit for continuous operation voids warranties and accelerates wear.

Q: What are the typical fuel consumption rates for Yuchai diesel generators?

Specific consumption varies by model and load, but representative figures show 205-215 g/kWh across the load range for modern HPCR-equipped engines. For practical planning, a 1,000 kW generator at 75% load consumes approximately 154 liters per hour. Compare these numbers to competing proposals using identical load profiles and operating conditions. Remember that fuel efficiency directly impacts lifecycle costs: a 15% advantage saves over $100,000 in fuel costs over 20 years for installations running 4,000+ hours annually.

Q: Can Yuchai generators integrate with existing building management or SCADA systems?

Yes. Modern Yuchai generator sets include microprocessor-based controllers supporting standard industrial protocols including Modbus RTU/TCP, CAN bus, and various proprietary systems. Controllers provide real-time monitoring of voltage, current, frequency, engine parameters, and alarm conditions. For facilities with multiple generators, paralleling controls enable automatic load sharing and redundancy. Specify your exact integration requirements (protocol, communication interface, monitoring parameters) during procurement to ensure compatibility with existing infrastructure。