Picture this: It’s 2 a.m., and a major storm has knocked out power to your facility. Your diesel generator kicks in immediately, keeping critical operations running. But then you ask yourself the question that keeps facility managers awake at night: how long can this thing actually run before it needs to stop?

The answer isn’t as simple as you might hope. How long a diesel generator can run continuously depends on several interconnected factors—from the generator’s power rating and fuel capacity to ambient conditions and maintenance status. Some generators are designed to run for just 200 hours per year during emergencies, while others can operate 24/7 for months on end.

Understanding these distinctions matters. Choose the wrong generator rating for your needs, and you might face an unexpected shutdown during a prolonged outage. Size your fuel system incorrectly, and you’ll run dry before utility power returns. That’s where manufacturers like Tesla Power come in—designing robust generator systems that match real-world runtime requirements rather than just theoretical maximums.

In this guide, we’ll walk through everything that determines diesel generator continuous runtime, from technical ratings and fuel logistics to monitoring tools and regulatory limits. By the end, you’ll know exactly how to specify, operate, and maintain a generator system that delivers reliable power for as long as you need it.

Figure 1: Industrial diesel generator installation in a professional facility setting. Modern generator systems combine robust mechanical design with advanced monitoring capabilities to ensure reliable continuous operation.

Understanding Key Terms and Generator Ratings

Before we dive into runtime numbers, you need to understand what “continuous operation” actually means in the generator world. It’s not just about leaving a machine running—it’s a specific technical classification with defined limits.

What Does Continuous Operation Mean?

Continuous operation refers to a generator’s ability to supply power without interruption for extended periods. But here’s the catch: the industry defines several different operational categories, each with its own runtime expectations and load characteristics. A generator rated for “continuous duty” is fundamentally different from one rated for “standby” use, even if they look identical on the outside.

The internationally recognized ISO 8528-1 standard establishes four primary power ratings that determine how long generators can run and under what conditions.

The Four Main Power Ratings

Emergency Standby Power (ESP): This is your typical backup generator rating. ESP generators are designed for variable loads during utility outages and are limited to around 200 hours per year of operation. These units can’t run indefinitely—they’re meant to bridge short-term power interruptions. Average load shouldn’t exceed 70% over a 24-hour period, and overload operation isn’t permitted.

Limited-Time Prime (LTP): A step up from standby, LTP generators can handle about 500 hours per year. They’re built for situations where you need more runtime than ESP provides but still don’t require year-round operation. Like ESP, these generators work with variable loads but have slightly more capacity for extended use.

Prime Rated Power (PRP): Now we’re talking serious runtime. Prime power generators can run for unlimited hours with varying loads. They’re rated for continuous operation throughout the year, with one important feature: they can handle a 10% overload for one hour in every 12-hour period (up to 25 hours per year total). Average load typically sits around 70% of rated capacity. If you’re running a remote site, a facility without grid connection, or any application requiring multi-day continuous operation, PRP is often your baseline.

Continuous Operating Power (COP): The marathon runner of generator ratings. Continuous duty diesel generators under COP classification can operate 24/7/365 at constant load—theoretically up to 8,760 hours per year, minus scheduled maintenance windows. Unlike PRP, COP doesn’t permit overload operation. These generators are engineered for base-loading applications, combined heat and power (CHP) systems, and facilities that genuinely need year-round power generation.

Load Capacity and Duty Cycles

Here’s something many people miss: generator load capacity directly impacts runtime capability. A generator rated at 500 kW doesn’t deliver 500 kW continuously under all conditions. Environmental factors like high ambient temperature or altitude reduce output through derating—sometimes by 15-20% or more.

Duty cycle matters too. Running a generator at 100% load continuously creates more thermal stress than operating at 70% load with periodic variation. That’s why PRP ratings build in headroom with that 70% average load guideline. It gives the engine breathing room and extends service intervals.

Why Rating Selection Matters for Runtime

Choose an ESP-rated generator for an application that needs 1,000 hours of annual runtime, and you’re violating the rating specifications. The engine isn’t built for that duty cycle. Cooling systems, lubrication intervals, and component durability all assume the usage pattern defined by the rating.

Conversely, specifying a COP generator when you only need 100 hours per year of standby service means you’re paying for overbuilt capacity you’ll never use. Smart runtime planning starts with matching your actual operational requirements to the correct ISO 8528 rating category.

Critical Factors Affecting Continuous Runtime

Knowing your generator’s power rating tells you the theoretical maximum runtime. But actual continuous operation in the real world? That depends on a half-dozen interrelated factors, any one of which can cut your runtime short.

Fuel Tank Capacity and Consumption Rates

This is the most obvious limiting factor, yet it’s where planning often falls short. Your runtime calculation starts with a simple formula: usable fuel volume divided by fuel burn rate at your expected load.

A typical industrial diesel generator consumes roughly 0.4 to 0.5 gallons per hour per kilowatt at full load. So a 500 kW generator running at 75% load (375 kW) burns approximately 150-190 gallons per hour. With a 1,000-gallon fuel tank, you’re looking at 5-7 hours of runtime before you need refueling. Want to run for 48 hours during a major outage? You’ll need either a much larger tank or a plan for fuel delivery.

Diesel generator fuel consumption isn’t linear, though. Generators typically run most efficiently at 70-80% of rated load. Drop below 30% load, and fuel efficiency falls off—and you risk issues like wet stacking (unburned fuel accumulating in the exhaust system). Push above 90% load, and consumption climbs while component stress increases.

Here’s a real-world consideration most people miss: usable fuel isn’t the same as tank capacity. You need to account for fuel system dead volume, and you should plan to refuel before completely draining the tank to avoid pulling sediment and water into fuel lines.

Generator Power Rating Classification

We covered ratings in the previous section, but it’s worth emphasizing how dramatically they affect continuous runtime:

- Standby generator operating hours are capped by design. EPA regulations typically limit stationary emergency generators to 200 hours per year for emergencies plus an additional 100 hours for testing and maintenance. Run beyond those limits outside of genuine emergencies, and you’re violating your air permit.

- Prime power generators remove those calendar-year restrictions. They’re built with more robust cooling systems, heavier-duty components, and lubrication systems designed for extended operation. Component service intervals are longer, and thermal management is more aggressive.

- COP generators take it further with constant-load optimization. Every subsystem—from cylinder liner design to alternator winding temperature management—is engineered assuming near-continuous operation.

Pick the wrong rating, and you’ll either face regulatory compliance issues or premature component wear that cuts runtime unexpectedly.

Load Percentage and Variability

Load level affects more than just fuel consumption—it impacts engine temperature, component wear, and even emissions compliance. Most diesel engines operate best between 60-80% of rated load. Run too light, and combustion temperatures drop, leading to incomplete fuel burn and carbon buildup. Run too heavy, and thermal stress accelerates wear.

Load variability also matters. A generator handling steady 70% load runs cooler and more efficiently than one cycling between 40% and 95% load every few minutes. Variable loads cause thermal cycling that stresses components and shortens service life.

Modern load banks and generator load capacity testing help you validate how your generator performs across its load range. Tesla Power systems, for example, include load profiling that tracks actual operating patterns and flags when your usage profile doesn’t match your rating classification.

Figure 2: Bulk diesel fuel storage system with integrated control and piping infrastructure. Proper fuel logistics planning is essential for extended continuous runtime, with tank capacity determining practical operational duration between refueling.

Cooling System Efficiency

Diesel engines reject huge amounts of heat during operation—often more thermal energy than electrical energy they produce. That heat has to go somewhere, and your cooling system’s ability to manage it defines your practical runtime limit.

Radiator-cooled generators depend on airflow and ambient temperature. When ambient temperatures climb above 90°F (32°C), cooling capacity drops. Many generators derate by 1-2% for every 5°F above their rated ambient temperature. In a 110°F equipment room, that could mean losing 8-10% of your rated capacity—potentially forcing load shedding or shutdown.

Parasitic loads matter too. The radiator fan itself can consume 20-30 kW on a large generator. That’s power that doesn’t reach your facility load, effectively reducing available capacity. If your 500 kW generator has 25 kW of parasitic load, you only have 475 kW available for your facility—and at full facility load, the generator is actually running at 105% of its net capacity. That’s a recipe for overheating during extended operation.

Ambient Temperature and Altitude

Environmental conditions hit generators from two directions: they reduce power output and they degrade cooling efficiency. Every manufacturer publishes derating tables, but many operators ignore them until it’s too late.

Temperature derating: Above the rated ambient temperature (often 77°F/25°C for standby generators or 104°F/40°C for prime/continuous units), expect to lose capacity. In extremely hot climates, derating can reach 15-20%.

Altitude derating: Diesel engines breathe air. Less air density at altitude means less oxygen for combustion. You’ll typically lose 3-4% of rated power for every 1,000 feet above sea level. At 5,000 feet, you’re down 15-20% from the nameplate rating.

Stack these factors—hot day, high altitude, high humidity—and a generator rated for 1,000 kW might only deliver 750 kW. If your facility demand is 900 kW, you’re in trouble. This is why proper sizing accounts for worst-case site conditions, not just nameplate ratings.

Maintenance Status and Service Intervals

Even a COP-rated generator designed for 8,760 hours per year can’t run indefinitely without maintenance. The phrase “unlimited hours” in rating specifications actually means “unlimited hours with appropriate scheduled maintenance.”

Typical service intervals for emergency backup generators during continuous operation:

- Daily checks: Coolant level, oil level, fuel level, visual inspection for leaks

- Weekly checks (for extended runs): Coolant pH and condition, belt tension, vibration monitoring

- Every 250-500 hours: Oil and filter changes, fuel filter replacement

- Every 500-1,000 hours: Air filter service, coolant condition testing

- Every 1,000-2,000 hours: Major inspection including valve adjustment, injector service, cooling system maintenance

Miss an oil change at 500 hours, and by 1,000 hours you might be looking at bearing damage. Skip coolant pH checks, and cylinder liner pitting can develop. These aren’t theoretical risks—they’re the common causes of unexpected shutdowns during extended continuous operation.

Generator maintenance schedules become compressed during continuous operation. An annual service interval on a lightly-used standby generator might come up every few weeks when running continuously. Planning for maintenance windows—and having the parts and expertise ready—is non-negotiable for true continuous duty.

The Compound Effect

Here’s what catches people: these factors don’t add—they multiply. High ambient temperature reduces power output and cooling efficiency. Altitude makes it worse. Running near 100% of derated capacity increases fuel consumption and thermal stress. Extended runtime compresses service intervals. One weak link cascades into others.

Smart runtime planning accounts for all these variables simultaneously, not individually. That’s how you design a generator system that actually delivers continuous operation when you need it, rather than one that looks good on paper but fails in a real outage.

Runtime Duration by Generator Type

So let’s get specific. How long can different generators actually run? The answer depends entirely on which classification you’re working with—and whether you’re talking about theoretical limits or practical operational reality.

Standby Generators: Designed for Short Bursts

Standby generators (ESP rating) are explicitly limited in runtime. The typical specification is 200 hours per year for emergency use, with an additional 100 hours available for testing and maintenance. During any single run, you can operate for as long as fuel lasts and the emergency condition persists—but those hours count against your annual total.

In practical terms, a standby generator with a 500-gallon fuel tank running at 60% load might deliver 12-15 hours before needing refueling. You can refuel and continue during a multi-day outage, but you’re burning through your annual hour allowance quickly.

Here’s a real-world scenario: A hospital with dual 750 kW standby generators experiences a 72-hour grid outage during a storm. Running both units continuously consumes 144 hours of their 200-hour annual emergency allocation. They’ve got 56 hours left for the rest of the year. Another major storm later that year, and they exceed their permit limits.

The limiting factor isn’t mechanical capability—it’s regulatory compliance. EPA permits for stationary emergency diesel engines restrict non-emergency operation to prevent these units from functioning as continuous power sources without meeting non-emergency emission standards.

Prime Power Generators: Built for the Long Haul

Prime power generators remove the calendar-year restrictions. They’re rated for unlimited annual hours with variable loads. This is where you see substantial differences in engine construction:

- Heavier crankshafts and connecting rods to handle extended operation

- More robust cooling systems with larger radiators

- Upgraded lubrication systems with higher-capacity oil sumps

- Component specifications assuming 3,000-6,000 hours per year of operation

A PRP generator can run continuously for weeks or even months, limited primarily by fuel supply and scheduled maintenance windows. In remote locations without grid power—mining sites, island facilities, military installations—prime-rated generators routinely log 4,000-8,000 hours annually.

Practical runtime between fuel stops? It depends on tank size. A 1,500 kW prime generator with a 2,000-gallon fuel tank, running at 70% load (1,050 kW), might consume 400-450 gallons per hour. That’s 4-5 hours between refueling. Install a 10,000-gallon bulk tank with automatic transfer pumps, and you’re looking at 20-25 hours between fill-ups—or longer with reduced load.

Continuous Duty Generators: The 24/7 Workhorses

Continuous duty diesel generators (COP rating) represent the top tier. These units are designed to run 8,760 hours per year minus only scheduled maintenance downtime. They’re common in:

- Base-load power generation at facilities without grid connection

- Combined heat and power (CHP) applications

- Data centers with Tier III/IV uptime requirements

- Industrial cogeneration systems

COP generators feature constant-load optimization. Because they don’t need to handle the 10% overload capability of PRP units, components can be precisely matched to steady-state operation. Cooling systems are sized for continuous heat rejection. Lubrication systems may include continuous oil filtration and conditioning.

Theoretical runtime? Unlimited, with maintenance windows. Practical runtime? Governed by maintenance intervals and fuel logistics. A well-maintained COP generator with proper fuel supply can operate for 6-12 months continuously before requiring extended maintenance shutdown.

Real-World Runtime Examples

Numbers tell the story:

Healthcare facility (U.S. Northeast): Four 1,000 kW prime-rated generators provide backup power for a hospital complex. During Hurricane Sandy in 2012, they ran continuously for 8 days (192 hours), with fuel delivery trucks arriving every 12-18 hours. Total fuel consumption exceeded 45,000 gallons.

Data center (Nevada): Six 2,500 kW COP generators in a Tier III facility handle base load while grid power serves as backup. These units log 7,500-8,000 hours annually, shut down only for scheduled 500-hour maintenance (quarterly). Each shutdown window is 8-12 hours.

Manufacturing plant (remote Alaska): Twin 3,000 kW prime generators provide sole power for an industrial facility with no grid connection. They run 24/7 year-round except for maintenance, accumulating 8,000+ hours annually. Bulk fuel tanks hold 50,000 gallons, providing 7-10 days between deliveries depending on load.

Generator Run Time Limits: What Actually Stops Extended Operation?

When continuous operation fails, it’s rarely because the generator “ran out of time.” Common limiting factors:

- Fuel logistics failure: Delivery delays, tank capacity miscalculation, fuel quality degradation

- Maintenance schedule violation: Missed oil changes, clogged filters, coolant degradation

- Thermal management breakdown: Cooling system failure, ambient temperature exceeding design limits

- Regulatory compliance: Exceeding permitted operating hours for emergency-rated units

- Component failure: Often traced back to deferred maintenance or operating outside rating specifications

Understand your generator’s rating classification, size your fuel system appropriately, and stay ahead of maintenance—and runtime becomes primarily a matter of fuel supply, not generator capability.

Figure 3: Multiple industrial generators in parallel configuration for mission-critical data center applications. Prime and continuous-rated generators in redundant configurations enable unlimited runtime capability with scheduled maintenance rotation.

Monitoring Tools and Management Systems

You can’t manage what you don’t measure. Extended continuous runtime demands active monitoring and control systems that track performance, predict issues, and enable remote management. Modern generator installations go far beyond a simple hour meter.

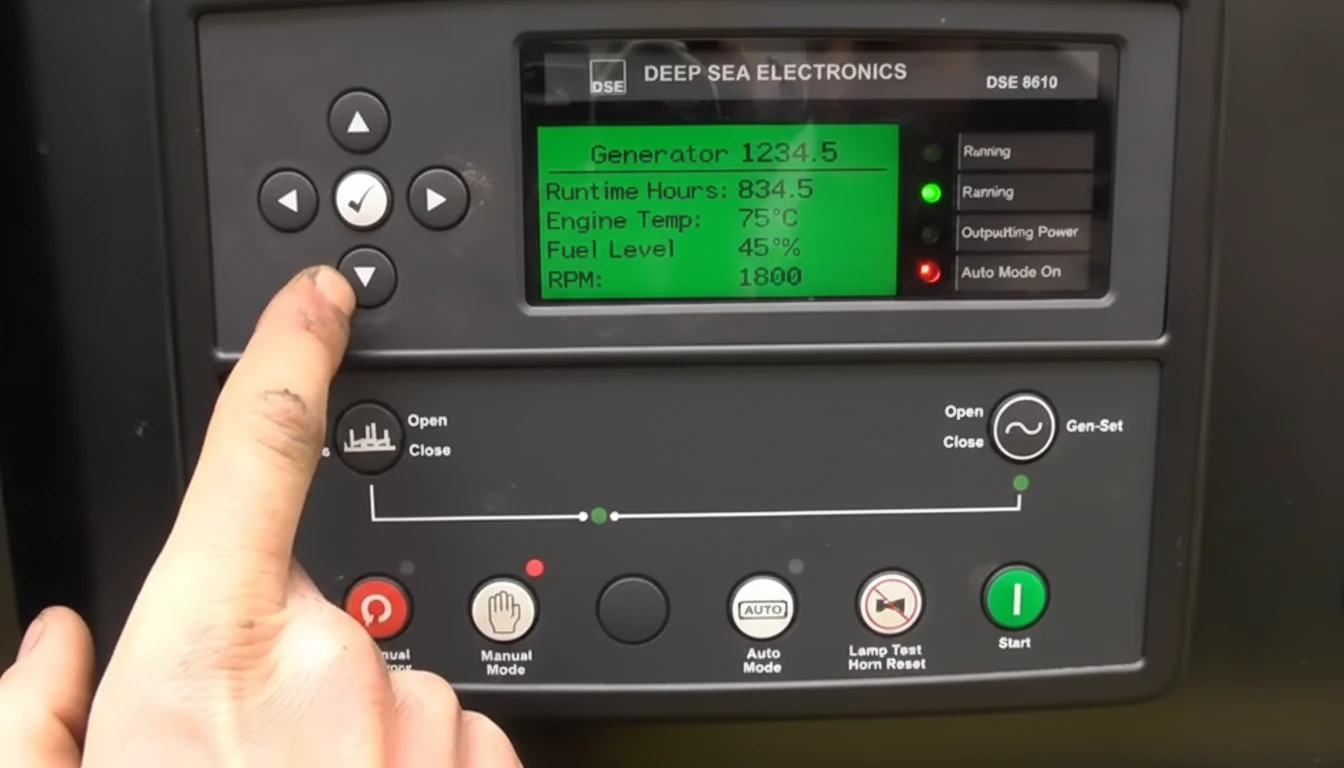

Digital Control Panels and Displays

Every modern generator includes a control panel, but capabilities vary dramatically. Basic units display voltage, frequency, and runtime hours. Industrial-grade panels—like those on Tesla Power generator systems—provide comprehensive operational data:

- Real-time load (kW and percentage of capacity)

- Engine parameters (coolant temperature, oil pressure, RPM)

- Fuel level and estimated runtime remaining

- Battery voltage and charging system status

- Alarm history and active fault codes

- Cumulative runtime and maintenance interval countdowns

These panels typically include configurable alarm thresholds. Set coolant temperature warnings at 210°F, and you’ll get advance notice before hitting the 220°F shutdown threshold. Configure low-fuel alarms at 25% tank capacity, and you have time to arrange delivery before hitting reserve levels.

Remote Monitoring Platforms

When generators run continuously, someone needs to watch them—24/7. Remote monitoring systems connect via cellular, Ethernet, or satellite links to provide:

- Real-time dashboard access: Check status from anywhere via web browser or mobile app

- Automatic alert notifications: Email, SMS, or push notifications for alarm conditions

- Historical data logging: Track load patterns, fuel consumption trends, runtime accumulation

- Multi-site management: Monitor entire fleets of generators from a central interface

For facilities running generators during extended outages, remote monitoring eliminates the need for constant on-site presence. Your facility manager gets a text alert if coolant temperature climbs or fuel level drops, rather than discovering problems during the next physical inspection.

Fuel Monitoring and Management Systems

Fuel logistics make or break extended runtime. Modern fuel monitoring includes:

- Ultrasonic or capacitive level sensors: Continuous fuel level measurement accurate to 1-2%

- Fuel consumption tracking: Calculated from runtime and load data, validated against level sensors

- Automatic refill alerts: Trigger fuel delivery orders when tanks reach predetermined thresholds

- Fuel quality monitoring: Some systems track fuel age and flag when tanks need cycling or treatment

Large installations often integrate automatic fuel transfer systems. When the day tank drops to 30%, pumps transfer fuel from bulk storage. When bulk storage hits 40%, the system generates a delivery order. Fully automated systems can sustain runtime for weeks without human intervention—assuming the fuel supplier keeps delivering.

Predictive Maintenance and Diagnostic Tools

Modern generators don’t just report current status—they predict future problems. Advanced systems monitor:

- Oil condition sensors: Measure viscosity, contamination, and remaining life

Figure 4: Modern generator control panel with digital monitoring display showing real-time operational parameters. Advanced control systems track runtime hours, load percentage, engine temperature, fuel consumption, and maintenance intervals for proactive management.

- Vibration analysis: Detect bearing wear, misalignment, or developing mechanical issues

- Exhaust temperature monitoring: Identify cylinder-specific problems or air filter restriction

- Battery health tracking: Predict battery failure before it prevents starting

Some systems use AI-driven analytics to establish performance baselines and flag deviations. When oil pressure trends downward over successive starts, or exhaust temperature on cylinder 3 climbs relative to others, the system flags it for investigation—often before it causes a shutdown.

Load Management and Paralleling Controls

Facilities with multiple generators need sophisticated paralleling controls. These systems:

- Synchronize generator output for parallel operation

- Balance load across multiple units for efficiency

- Enable automatic load shedding if generation capacity becomes insufficient

- Coordinate generator starts and stops based on total facility demand

- Manage spinning reserve (kept ready but unloaded for fast response to load changes)

A hospital with four 1,000 kW generators might run two at 70% load during normal operation, keep one in spinning reserve, and hold one offline for maintenance. Load management systems make this coordination automatic, seamless, and reliable.

Integration with Building Management Systems

The most sophisticated installations integrate generator monitoring with building management systems (BMS). This enables:

- Automatic load prioritization during capacity constraints

- Coordination between generators and UPS systems

- HVAC setpoint adjustments to reduce electrical load

- Automated shutdown of non-critical loads if runtime must be extended

During an extended outage, the BMS might automatically raise data center cooling setpoints by 2°F to reduce generator load by 50 kW—extending fuel supply by hours without impacting uptime.

Best Practices for Maximizing Runtime

Theory is one thing. Practical, reliable extended runtime requires disciplined planning and execution across multiple dimensions. Here’s what separates facilities that confidently run generators for days or weeks from those that face unexpected shutdowns.

Start with Proper Sizing and Rating Selection

This is where runtime success begins—before you ever purchase equipment. Match your generator rating to your actual operational requirements:

- For true backup-only applications: ESP (standby) rating is appropriate and cost-effective, but plan for refueling logistics if extended outages are possible in your region.

- For applications expecting frequent or extended outages: PRP (prime) rating provides the flexibility and component durability you need. Pay the upfront premium to avoid premature wear.

- For continuous or near-continuous operation: COP rating is non-negotiable. Don’t try to save money with a PRP unit when you need COP reliability.

Size for worst-case conditions, not nameplate capacity. Account for:

- Altitude derating (3-4% per 1,000 feet)

- Temperature derating (manufacturer tables)

- Parasitic loads (cooling fans, fuel pumps)

- Future load growth (plan 20-30% headroom)

Tesla Power engineers routinely see facilities that sized generators for average load at sea level and 77°F—then discover they’re 15-20% undersized when operating at full load in a 105°F equipment room at 3,000 feet elevation.

Design Fuel Logistics for Your Runtime Target

Fuel capacity should align with your runtime goals plus safety margin:

24-hour minimum runtime: Standard for most commercial backup applications. Calculate fuel consumption at 75% average load, add 25% safety margin, then size your tank accordingly.

72-hour target: Common for healthcare, data centers, and critical infrastructure. This often requires bulk fuel storage (5,000-20,000 gallons) with automatic transfer systems.

Week-plus operation: Demands established fuel delivery contracts with guaranteed availability during emergencies. Your contract should specify maximum delivery time and backup supplier arrangements.

Consider EPA SPCC regulations if your total aboveground diesel storage exceeds 1,320 gallons in containers of 55+ gallons each. SPCC compliance requires a formal plan and secondary containment—factor this into your fuel system design.

Implement Rigorous Maintenance Schedules

Maintenance intervals compress dramatically during continuous operation. A generator maintenance schedule that works for 50 hours per year collapses when you run 500 hours in a week.

Establish three maintenance tiers:

Tier 1 – Daily checks during continuous operation:

- Visual inspection for leaks, unusual noise, excessive vibration

- Coolant level (check when cool)

- Oil level

- Fuel level and consumption rate validation

- Control panel alarm review

Tier 2 – Service intervals by runtime hours:

- 250-500 hours: Oil and filter change, fuel filter replacement

- 500-1,000 hours: Air filter service, coolant system inspection, belt tension check

- 1,000-2,000 hours: Major service including valve adjustment, injector inspection, cooling system maintenance

Tier 3 – Shutdown after extended run:

- Comprehensive inspection within 48 hours of returning to standby

- Oil analysis to check for contamination or wear metals

- Coolant pH and additive concentration testing

- Load bank test to verify performance

Stock critical spare parts on-site: oil filters, fuel filters, belts, coolant, and sufficient oil for at least two complete changes. During a multi-day outage isn’t the time to discover your oil filter is on backorder.

Figure 5: Professional technicians conducting scheduled maintenance on industrial generator equipment. Regular maintenance at compressed intervals during continuous operation is critical for sustained reliability and preventing unexpected shutdowns.

Manage Load Strategically

How you load a generator affects runtime capability as much as the generator itself.

Optimize load levels: Target 60-75% of rated capacity for best efficiency and longevity. Avoid sustained operation below 30% (wet stacking risk) or above 90% (thermal stress).

Minimize load cycling: Frequent large load swings create thermal stress. If possible, stage load changes gradually. Bring large loads online in steps rather than all at once.

Plan load shedding priorities: Identify which loads can be shed if runtime must be extended or capacity becomes constrained. Building management systems can automate this—non-critical HVAC zones drop offline first, then general lighting, then non-essential equipment.

Load diversity: If running multiple generators, distribute load to balance utilization and create maintenance opportunities. Don’t run one unit at 95% and another at 40%—balance them both around 70%.

Monitor Environmental Conditions Actively

Ambient temperature and ventilation directly impact runtime capability:

- Ensure adequate combustion air supply (generators consume huge volumes)

- Maintain equipment room temperature within design limits through ventilation or cooling

- Monitor intake air temperature, not just room temperature

- Account for solar heat gain on outdoor installations

- Clean radiator fins and ensure unobstructed airflow

A generator derated 10% due to poor ventilation doesn’t just lose capacity—it runs hotter, reducing component life and increasing maintenance frequency. Fix the ventilation, and you recover both capacity and reliability.

Establish Clear Operating Protocols

Document and train staff on:

- Startup and shutdown procedures specific to extended runtime scenarios

- Refueling protocols (never refuel a hot engine, always ground the tanker)

- When to escalate issues (what’s “monitor” vs. “call service immediately”)

- Maintenance schedules and task checklists

- Emergency shutdown criteria

During Hurricane Katrina, some facilities ran generators for 10+ days successfully. Others failed within 48 hours. The difference wasn’t equipment quality—it was operational discipline.

Leverage Manufacturer Expertise

Manufacturers like Tesla Power offer application engineering support that goes beyond equipment selection. Take advantage of:

- Site-specific derating calculations

- Fuel system design review

- Maintenance interval recommendations based on your specific duty cycle

- Remote monitoring and diagnostic support during extended operation

- Emergency parts availability during prolonged outages

The cost of engineering support is negligible compared to the cost of unexpected shutdown during a critical outage. Use it.

Regulatory and Safety Considerations

Runtime capability means nothing if regulatory limits prevent you from actually operating your generator. Understanding the legal framework is as important as understanding the technical specifications.

EPA Usage Limitations for Emergency Generators

The EPA distinguishes between “stationary emergency” and “non-emergency” diesel engines, and this classification fundamentally affects permissible runtime.

Emergency engines can operate unlimited hours during genuine emergencies (utility power outages and similar conditions). However, non-emergency operation is restricted:

- Up to 100 hours per year for maintenance and testing

- Potentially up to 50 additional hours per year for non-emergency operation (jurisdiction-dependent and often requiring specific permit conditions)

Exceed these limits, and you’re operating an emergency engine as a non-emergency source—which violates air quality permits and can trigger substantial penalties.

Non-emergency engines (including prime and continuous ratings) face different regulatory requirements. They’re permitted for unlimited operation but typically must meet more stringent emission standards and may require emission control equipment that emergency engines don’t need.

When specifying a generator, match the EPA usage category to your actual operational intent. If you genuinely need unlimited runtime capability outside of emergencies—base-load generation, peak shaving, demand response—you need a non-emergency rated engine with appropriate emission controls.

NEC Electrical Code Requirements

The National Electrical Code (NFPA 70) classifies backup power systems and imposes requirements based on application:

- Article 700 – Emergency Systems: Legally mandated systems for life safety. Includes automatic transfer, fuel for 2+ hours operation, and strict maintenance requirements.

- Article 701 – Legally Required Standby: Systems required by municipal, state, or federal code. Similar requirements to Article 700.

- Article 702 – Optional Standby: Voluntary backup systems. Less stringent requirements.

- Article 708 – Critical Operations Power Systems (COPS): For facilities requiring continuous operation (data centers, certain industrial processes).

Your electrical classification determines testing frequency, maintenance documentation requirements, and acceptable downtime for maintenance. COPS facilities, for example, must coordinate generator maintenance to avoid compromising redundancy.

Conclusion

So, how long can a diesel generator run continuously? The answer spans from 200 hours per year for basic standby units to truly unlimited operation for continuous-duty systems—but the real answer depends on how you’ve matched equipment, fuel logistics, maintenance discipline, and regulatory compliance to your specific needs.

A properly specified prime power generator or continuous duty diesel generator with adequate fuel supply and disciplined maintenance can run for weeks or months. But achieving that capability requires understanding the compound effects of rating classification, load management, environmental conditions, and maintenance compression during extended operation.

The facilities that achieve reliable extended runtime don’t rely on luck or hope—they engineer for it. They size for worst-case conditions, plan fuel logistics with safety margins, implement compressed maintenance schedules, monitor systems actively, and respect regulatory boundaries.

If your facility faces the realistic possibility of multi-day or multi-week outages, invest the time now to validate your generator specifications, fuel capacity, and operational protocols. Partner with manufacturers like Tesla Power who understand the difference between theoretical ratings and real-world continuous operation. The middle of an extended outage is not the time to discover your generator’s limitations.

Your backup power system is only as reliable as your worst-planned element. Make runtime planning as rigorous as equipment selection, and you’ll have confidence when the grid goes down.

Frequently Asked Questions

1. How many hours can a diesel generator run without stopping?

The answer depends entirely on the generator’s power rating classification. Emergency standby (ESP) generators are limited to approximately 200 hours per year for emergency use, though any single run can continue as long as fuel lasts and the emergency persists. Prime power (PRP) and continuous operating power (COP) generators can run unlimited hours annually with proper maintenance and fuel supply. COP generators are specifically designed to operate 24/7/365 minus only scheduled maintenance windows. The practical limit for continuous operation is typically determined by maintenance intervals—most generators require oil and filter changes every 250-500 hours of continuous operation—and fuel logistics rather than any inherent mechanical limitation for properly rated units.

2. What is the difference between prime and standby generators?

Standby generators (ESP rating) are designed for emergency backup during utility outages and are legally restricted to about 200 hours of emergency operation plus 100 hours of testing per year under EPA regulations. They’re built for intermittent use with variable loads and cannot handle sustained operation or overload conditions. Prime generators (PRP rating) are built for unlimited hours of operation throughout the year with more robust components, enhanced cooling systems, and heavier-duty construction. They can handle varying loads continuously and permit a 10% overload for one hour in every 12-hour period. Prime generators have longer service intervals and are appropriate for applications requiring frequent or extended runtime, remote sites without grid power, or facilities expecting multi-day outages.

3. How much fuel does a generator use during continuous operation?

Diesel generator fuel consumption typically ranges from 0.4 to 0.5 gallons per hour per kilowatt (gal/hr/kW) at full load, though efficiency varies with load percentage. A 500 kW generator operating at 75% load (375 kW) burns approximately 150-190 gallons per hour. At optimal load (70-80% of capacity), generators achieve best fuel efficiency. Consumption increases when operating above 90% load due to thermal stress, and efficiency drops below 30% load with increased risk of wet stacking. For runtime planning, calculate fuel needs using: (generator kW rating × load percentage × 0.4 to 0.5 gal/hr/kW), then add 20-25% safety margin and account for parasitic loads from cooling fans and auxiliary systems. A 1,000-gallon fuel tank supporting a 500 kW generator at 70% load provides approximately 5-7 hours of continuous operation.

4. When should I service a continuously running generator?

Maintenance intervals compress dramatically during continuous operation. Daily checks should include visual inspections for leaks, coolant level verification, oil level checks, fuel monitoring, and control panel alarm reviews. Oil and filter changes are required every 250-500 hours of continuous runtime—potentially as often as every 10-20 days during extended operation. Every 500-1,000 hours requires air filter service, coolant system inspection, and belt tension checks. Major service including valve adjustment, injector service, and cooling system maintenance is needed every 1,000-2,000 hours. After any extended run (multiple days or weeks), conduct comprehensive inspection within 48 hours including oil analysis, coolant testing, and load bank validation. Stock critical spare parts on-site—oil filters, fuel filters, belts, and coolant—because supply chain delays during emergencies can force unnecessary shutdowns.

5. Can I run a standby generator continuously during a long power outage?

Technically yes, but with important limitations. Mechanically, a standby generator can run continuously as long as fuel supply continues and maintenance is performed—the engine won’t automatically shut down after reaching a time limit. However, you face two constraints: regulatory and durability. EPA regulations for stationary emergency generators limit annual operation, so a multi-week outage consumes your entire year’s permitted emergency hours. Additionally, standby generators lack the robust cooling systems, heavy-duty components, and extended lubrication capacity of prime or continuous-rated units. Components experience accelerated wear during extended operation beyond design intent. If your facility realistically faces multi-day or multi-week outages, specify prime-rated or continuous-rated generators during initial procurement—they’re engineered for sustained operation and avoid regulatory limitations on runtime. Using a standby generator for extended continuous operation is borrowing against future reliability.