Picture this: a severe storm rolls through your area at 2 a.m., and suddenly your facility goes dark. Your data center, manufacturing line, or hospital depends on uninterrupted power—and within seconds, a diesel generator kicks in, restoring operations before critical systems fail. But have you ever wondered exactly how these machines convert fuel into the electricity that keeps your business running?

Understanding how a diesel generator works isn’t just technical curiosity. When you’re investing tens or hundreds of thousands of dollars in a backup power system, knowing the mechanics helps you make smarter purchasing decisions, communicate effectively with vendors, and spot potential issues before they become costly downtime. Whether you’re evaluating your first standby generator or upgrading an existing system, grasping the fundamentals puts you in control.

In this guide, we’ll walk through every stage of diesel generator operation—from the moment fuel enters the combustion chamber to the instant electricity flows to your critical loads. You’ll learn what each component does, which factors affect performance, and how to optimize your system for maximum reliability and fuel efficiency. Let’s pull back the curtain on the engine that powers your business.

What Is a Diesel Generator? Breaking Down the Basics

At its core, a diesel generator (often called a genset) is a self-contained power production system that combines two primary elements: a diesel engine and an alternator. Think of it as a partnership—the engine provides mechanical muscle, while the alternator transforms that rotational motion into usable electrical current.

Unlike gasoline generators that rely on spark plugs for ignition, diesel generators use compression ignition. Air inside the cylinder gets squeezed to extremely high pressure, raising its temperature to over 500°C. When diesel fuel sprays into this superheated air, it ignites spontaneously—no spark needed. This fundamental difference makes diesel systems more robust, more efficient, and better suited for heavy-duty, long-duration operation.

Diesel generators come in many sizes and configurations. A small portable diesel generator might deliver 5-10 kW for construction sites or remote work locations, while industrial units from manufacturers like Tesla Power can produce several megawatts to power entire factories or data centers during a power outage. But regardless of size, the core operating principle remains the same: convert chemical energy in diesel fuel into mechanical rotation, then into electrical power your equipment can use.

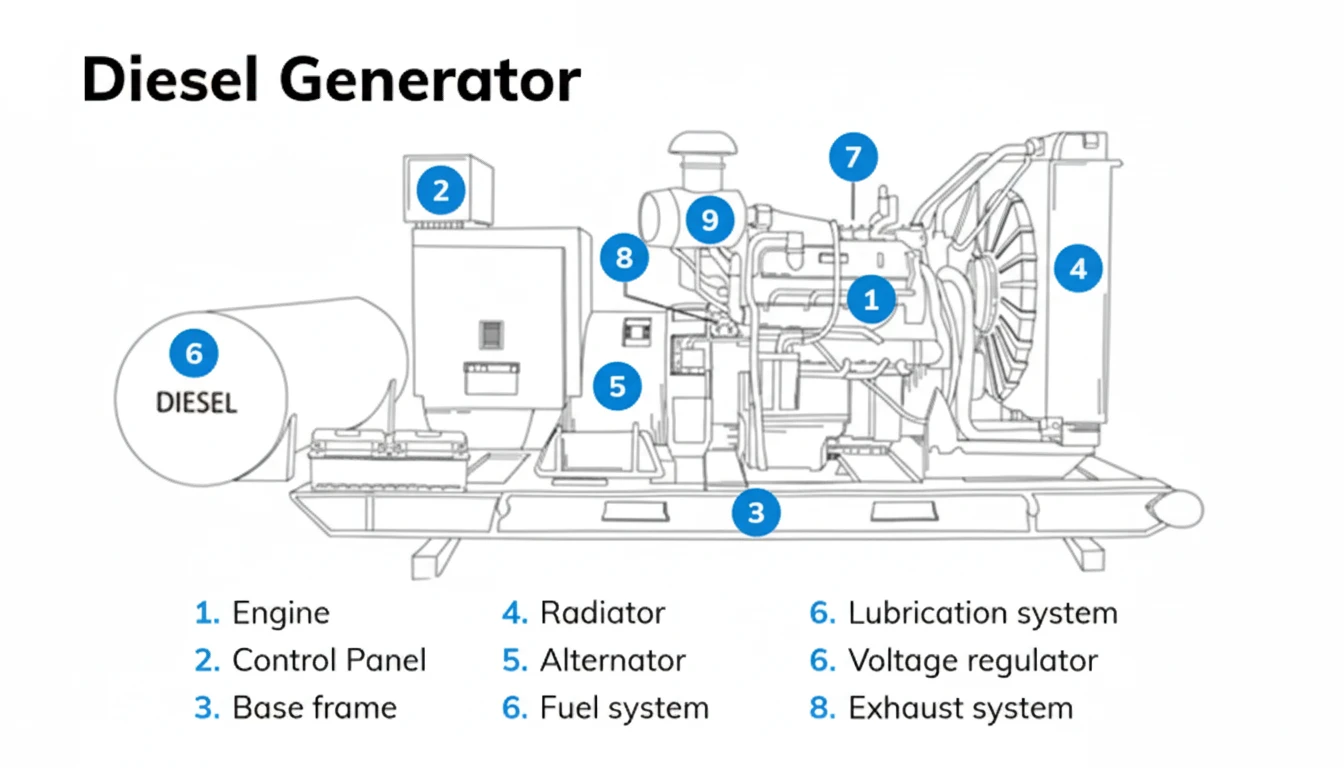

The genset includes more than just engine and alternator. A complete system incorporates fuel storage and delivery, cooling (radiator or heat exchanger), exhaust management, lubrication, and a control panel that monitors performance and manages start/stop sequences. Understanding these supporting systems is just as important as understanding combustion itself.

Figure 1: Cross-sectional view of a diesel generator showing the major components including the diesel engine, alternator, fuel system, cooling radiator, exhaust system, and control panel. Understanding these interconnected systems is essential for proper operation and maintenance.

Core Components: The Building Blocks of Power Generation

To understand how a diesel generator produces electricity, you need to know what’s inside the housing. Each component plays a specific role in the energy conversion chain. Let’s break down the essential parts:

The Diesel Engine: Prime Mover

The diesel engine is where everything starts. It operates on a four-stroke cycle—intake, compression, power, and exhaust. During the intake stroke, fresh air (only air, no fuel yet) enters the cylinder through an open valve. The compression stroke then squeezes this air to roughly 1/15th of its original volume, generating intense heat.

At the peak of compression, fuel injectors spray a fine mist of diesel into the cylinder. The heat from compressed air causes instant ignition, driving the piston down in the power stroke. Finally, the exhaust stroke expels combustion gases, and the cycle repeats. Modern diesel engines can sustain this process thousands of times per minute, delivering smooth, consistent mechanical power.

The Alternator: Electrical Converter

The alternator (technically a synchronous generator) is bolted directly to the engine’s crankshaft. As the engine spins, it rotates a magnetic field inside the alternator. This moving magnetic field cuts through copper windings, inducing an alternating current (AC) through electromagnetic induction—the same principle Michael Faraday discovered nearly two centuries ago.

The alternator’s automatic voltage regulator (AVR) constantly adjusts the magnetic field strength to maintain stable output voltage, even when your electrical load suddenly increases or decreases. Quality alternators from companies like Tesla Power can respond to load changes within milliseconds, preventing voltage sags that could damage sensitive electronics.

Fuel System: Reliable Delivery

The fuel system stores diesel and delivers it to the engine at precisely the right pressure and timing. It includes a fuel tank (often integrated into the generator base), fuel lines, filters, and high-pressure injection pumps. Fuel filters are critical—they remove water and contaminants that could damage injectors or reduce combustion efficiency.

Many industrial gensets feature dual fuel filters arranged in a primary/secondary configuration, allowing you to change one filter while the engine continues running. This design supports continuous power operation during extended outages.

Cooling System: Temperature Management

Combustion generates tremendous heat, and the cooling system prevents engine damage by maintaining safe operating temperatures. Most generators use liquid cooling—a mixture of water and coolant circulates through passages in the engine block, absorbs heat, then passes through a radiator where airflow dissipates that heat to the atmosphere.

Cooling system capacity is a critical specification. An undersized radiator can cause overheating during hot weather or high-load conditions, forcing the generator to shut down exactly when you need it most. This is why proper cooling design matters for reliable backup power system performance.

Exhaust System: Emissions Management

Exhaust gases—primarily nitrogen, carbon dioxide, water vapor, and trace pollutants—exit through the exhaust manifold and muffler. Industrial installations typically route exhaust outside the building via insulated pipes. Modern diesel generators often include emission control technologies to meet environmental regulations.

Lubrication System: Friction Reduction

Engine oil under pressure lubricates moving parts (pistons, crankshaft, bearings), reducing friction and carrying away heat. An oil pump continuously circulates lubricant from the oil pan through galleries in the engine. Oil filters trap metal particles and combustion byproducts to keep the oil clean.

Oil condition directly impacts engine longevity. Contaminated or degraded oil accelerates wear, so regular oil analysis and scheduled changes are non-negotiable for any serious standby generator program.

Control Panel and Monitoring Systems

The control panel is the generator’s brain. It monitors engine parameters (oil pressure, coolant temperature, battery voltage), manages automatic start/stop sequences, and displays alarms when something goes wrong. Modern controllers can communicate via Ethernet or cellular networks, sending alerts to facility managers’ smartphones before a minor issue becomes a catastrophic failure.

Advanced systems perform automatic load transfer—detecting utility power loss, starting the generator, waiting for it to reach stable voltage and frequency, then switching your critical loads from grid to generator power, all within seconds and without human intervention.

How Does a Diesel Generator Work Step-by-Step?

Figure 2: Industrial diesel generators installed in a commercial facility. These backup power systems provide continuous power during utility outages, protecting critical operations from costly downtime.

Now that you know the components, let’s walk through the complete operational sequence—from the moment the control panel detects a power failure to the instant your facility is back online.

Step 1: Power Loss Detection and Start Sequence

When utility power fails, the control panel senses the voltage drop within milliseconds. If configured for automatic operation, the controller immediately signals the starter motor to crank the engine. The battery (typically 12V or 24V depending on generator size) provides the electrical energy needed to spin the engine during starting.

As the engine cranks, several things happen simultaneously. The fuel system pressurizes, delivering diesel to the injectors. The oil pump begins circulating lubricant. Air rushes into the cylinders through the intake manifold. Within a few crankshaft revolutions, compression heats the air sufficiently for combustion to begin.

Most industrial gensets reach operating speed (typically 1500 or 1800 RPM) within 10-15 seconds of receiving the start command. Smaller portable units may start even faster.

Step 2: Combustion and Mechanical Power Generation

Once the engine fires, the four-stroke cycle takes over. Let’s follow one cylinder through a complete cycle:

Intake: The piston moves down, creating a vacuum that draws fresh air through the open intake valve. No fuel enters yet—only air.

Compression: Both valves close. The piston moves up, compressing the air to approximately 500 psi (34 bar) in typical engines, though high-performance units may exceed 1000 psi. This compression raises air temperature above diesel’s ignition point.

Power (Combustion): At the top of the compression stroke, injectors spray atomized diesel fuel into the cylinder. The superheated air ignites the fuel instantly. Expanding gases from combustion drive the piston down forcefully, turning the crankshaft.

Exhaust: The exhaust valve opens, and the rising piston pushes spent gases out of the cylinder. The cycle immediately repeats.

In a multi-cylinder engine (most generators have 4, 6, or more cylinders), these cycles are staggered so power strokes overlap, producing smooth, continuous rotation. The crankshaft converts the pistons’ reciprocating motion into rotational mechanical energy.

Step 3: Electrical Generation via Electromagnetic Induction

The crankshaft drives the alternator rotor at a precise speed—typically 1800 RPM for 60 Hz output or 1500 RPM for 50 Hz. The rotor contains powerful electromagnets (energized by a small DC excitation current), creating a rotating magnetic field.

As this magnetic field spins inside stationary copper windings (the stator), it induces voltage in those windings. The rate of magnetic field change determines output frequency; the field strength determines voltage magnitude. This is electromagnetic induction in action—the same principle that powers everything from tiny phone chargers to massive power plants.

The alternator produces three-phase AC power in most commercial units, though single-phase configurations exist for smaller residential applications. Three-phase output delivers more power with better efficiency and smoother characteristics for motors and large equipment.

Step 4: Voltage Regulation and Frequency Control

As your facility’s electrical load changes—lights turn on, HVAC compressors cycle, computers boot up—the generator must maintain stable voltage and frequency. Two control systems handle this:

Voltage regulation: The automatic voltage regulator (AVR) monitors output voltage continuously. When voltage drops (load increase), the AVR increases DC excitation current to the rotor, strengthening the magnetic field. When voltage rises (load decrease), it reduces excitation. Quality AVRs maintain voltage within ±1% of setpoint.

Frequency (speed) control: The engine governor controls fuel delivery to maintain constant RPM. More load tries to slow the engine, so the governor opens the fuel valve wider. Less load causes speed to rise, so the governor restricts fuel. Electronic governors on modern gensets respond within milliseconds, keeping frequency rock-steady.

This coordination between AVR and governor ensures continuous power quality that meets or exceeds utility grid standards.

Step 5: Load Transfer and Continuous Operation

Once the generator reaches stable voltage and frequency (typically 5-10 seconds after starting), the automatic transfer switch (ATS) disconnects your facility from the dead utility line and connects it to the generator. The switchover happens so quickly that computers and sensitive equipment never notice the transition.

The generator then operates continuously, supporting your full electrical load. Fuel consumption varies with load—a 100 kW unit running at 50% load (50 kW) might consume 3-4 gallons per hour, while running at full load could require 6-7 gallons per hour. This is where fuel efficiency and proper load management become financially significant.

Cooling, lubrication, and exhaust systems all operate continuously, managed by the control panel. If any parameter goes out of range—oil pressure too low, coolant temperature too high—the controller triggers alarms and, if necessary, initiates a controlled shutdown to protect the engine.

Step 6: Utility Restoration and Shutdown

When utility power returns and stabilizes, the control panel detects it. After confirming the grid voltage and frequency are acceptable (usually a 5-minute delay to avoid false positives), the ATS switches your facility back to utility power.

The generator doesn’t shut down immediately. Instead, it runs at no-load or reduced load for several minutes (a “cool-down period”), allowing oil and coolant to stabilize temperatures before stopping. This cool-down cycle extends engine life significantly.

Finally, the controller signals the engine to stop, fuel delivery ceases, and the genset returns to standby mode—ready to start again within seconds if needed.

What Factors Influence Diesel Generator Efficiency?

Understanding the operational process is one thing; optimizing it for efficiency and longevity is another. Several factors dramatically affect how well your generator performs and how much each kilowatt-hour costs you.

Load Management: The 70% Rule

Diesel engines operate most efficiently at 70-80% of their rated capacity. Running consistently below 30% load causes “wet stacking”—unburned fuel accumulates in the exhaust system, leading to carbon buildup, increased emissions, and potential engine damage. Running continuously above 90% load shortens engine life and reduces the safety margin for load spikes.

When specifying a generator, size it so your typical operating load falls in that 70-80% sweet spot. If your critical load is 60 kW, a 75-80 kW generator will run more efficiently than a 150 kW unit that’s perpetually underloaded. This is where working with experienced manufacturers like Tesla Power pays off—their application engineers can help you right-size your system based on actual load profiles, not just peak demand.

Fuel Quality and Storage Conditions

Diesel fuel degrades over time. Microorganisms grow in fuel tanks, especially when water contamination is present. Fuel oxidation produces gums and sediments that clog filters and injectors. In standby generator applications where fuel might sit for months between runs, degradation becomes a real concern.

Best practices for fuel management include:

- Biocide additives to prevent microbial growth in long-term storage

- Fuel stabilizers to slow oxidation

- Regular fuel polishing (filtering and recirculating stored fuel)

- Water removal from tank bottoms where condensation accumulates

- Fuel testing annually to verify cetane rating and contamination levels

Poor fuel quality can reduce fuel efficiency by 10-15% and lead to injector failures that cost thousands in repairs.

Ambient Temperature and Altitude Effects

Diesel engines breathe air, and air density affects power output. At higher altitudes, thinner air means less oxygen per cylinder per cycle, reducing combustion efficiency and available power. Most manufacturers derate generator capacity by approximately 3-4% per 1,000 feet above sea level.

High ambient temperatures also force derating. If your generator is rated at 25°C (77°F) but operates in 40°C (104°F) conditions, expect a 5-10% capacity reduction. This matters enormously in hot climates or when generators are installed in poorly ventilated enclosures.

Always verify that your generator’s actual available capacity—after derating for your specific altitude and temperature conditions—still meets your load requirements with appropriate margin.

Maintenance Discipline

No factor affects long-term efficiency and reliability more than maintenance. Key maintenance tasks directly impact performance:

- Oil changes: Fresh oil reduces friction and removes combustion byproducts. Follow manufacturer intervals religiously.

- Air filter replacement: Clogged air filters starve the engine of oxygen, reducing power and increasing fuel consumption.

- Coolant system service: Degraded coolant loses its ability to prevent corrosion and manage heat.

- Fuel filter changes: Protect injectors from the costly damage contaminated fuel causes.

- Battery maintenance: A dead battery means a generator that won’t start, no matter how perfect the rest of the system is.

Proactive maintenance doesn’t just prevent failures—it preserves efficiency. A well-maintained generator consumes less fuel, produces cleaner power, and lasts decades. A neglected one becomes unreliable within years.

Monitoring Tools and Technologies That Optimize Performance

Modern diesel generators aren’t just mechanical devices—they’re smart systems that collect data, predict problems, and communicate status in real time. These monitoring technologies transform reactive maintenance into predictive management.

Remote Monitoring Platforms

Cloud-based monitoring systems like PowerCommand Cloud, ComAp WebSupervisor, and similar platforms let you track generator status from anywhere. These systems provide:

- Real-time alerts: Get notified immediately when faults occur, often before the generator shuts down

- Historical trending: Analyze engine temperature, oil pressure, and load patterns over weeks or months

- Multi-site dashboards: Manage dozens of generators across different locations from one interface

- Predictive maintenance scheduling: System algorithms flag components approaching service intervals

For organizations with multiple facilities or distributed backup power system infrastructure, remote monitoring can reduce service calls by 30-40% and virtually eliminate surprise failures.

Automatic Transfer Switches (ATS)

The ATS is more than a switch—it’s an intelligent coordinator between utility and generator power. Modern transfer switches monitor both sources continuously, detecting voltage sags, frequency deviations, and phase imbalances that signal grid problems. They initiate generator starts, verify output quality before transferring load, and manage the return to utility power.

Some advanced ATS units can perform “soft loading,” gradually ramping generator load up instead of hitting the engine with full load instantly. This extends engine life significantly.

Load Banks for Testing

A load bank is a device that simulates electrical load, allowing you to test your generator at realistic power levels without actually disconnecting building loads. Regular load bank testing (monthly or quarterly for critical systems) ensures the generator can actually deliver its rated output when a real power outage occurs.

Load bank testing also prevents wet stacking by running lightly loaded gensets at higher output levels periodically, burning off carbon deposits and keeping combustion chambers clean.

Digital Control Panels

Microprocessor-based controllers have replaced mechanical gauges and switches. These digital panels provide precise measurements, programmable start/stop sequences, multi-language displays, and communication protocols (Modbus, SNMP, BACnet) that integrate with building management systems.

Some controllers include built-in exercisers that automatically start the generator weekly at pre-set times, run it for a specified duration, then shut it down—maintaining readiness without human intervention.

How to Get Better Performance: Industry Best Practices

Figure 3: Modern digital control panel with comprehensive monitoring displays showing engine parameters, voltage, frequency, and alarm systems. Advanced controllers enable remote monitoring and predictive maintenance capabilities.

Knowing how generators work is valuable, but applying that knowledge through proven operational practices delivers the real ROI. Here’s what separates installations that deliver decades of reliable service from those that disappoint:

Exercise Your Generator Regularly

A generator that sits idle for months develops problems. Fuel system seals dry out, batteries discharge, coolant settles, and control circuits can fail. Industry standards (NFPA 110 for emergency power systems) typically require monthly exercise cycles.

Best practice: Run your generator under load for at least 30 minutes monthly. Not just a quick start—actually transfer building load or connect a load bank so the engine reaches normal operating temperature. This keeps all systems functional and reveals developing problems before an emergency.

Document Everything

Create and maintain detailed records:

- Installation documentation and as-built drawings

- Manufacturer manuals and parts lists

- Maintenance logs with dates, technician names, and work performed

- Exercise and load test results

- Fuel quality test reports

- Alarm history and fault codes

Good documentation helps technicians diagnose problems faster, supports warranty claims, and provides the data needed to forecast major service events. It also demonstrates due diligence in regulatory inspections.

Implement Redundancy Where It Matters

For truly critical applications—hospitals, data centers, emergency services—a single generator is a single point of failure. N+1 redundancy (one more generator than technically required) provides resilience when one unit needs maintenance or fails. Parallel operation with automatic load sharing ensures continuous power even if a genset goes offline.

Tesla Power and other quality manufacturers offer sophisticated paralleling controls that synchronize multiple generators, distribute load proportionally, and seamlessly handle units entering or leaving the system.

Size for the Application, Not Just Peak Load

Oversizing causes as many problems as undersizing. A generator rated for twice your actual load runs chronically underloaded, accumulating carbon deposits and wasting fuel. Instead, size the generator for your sustained operating load (that 70-80% efficiency sweet spot), and handle transient peaks through proper motor starting arrangements or soft-start controls.

Consider load sequencing—starting large motors one at a time rather than simultaneously—to reduce inrush current and allow a smaller, more efficient generator.

Choose Quality Over Initial Price

The generator market spans from budget-grade consumer units to industrial-hardened systems built for decades of service. The price difference is real, but so is the performance gap. Industrial gensets feature:

- Heavy-duty engines designed for continuous operation

- Superior alternators with better voltage regulation

- Robust enclosures with effective sound attenuation

- Advanced controls with comprehensive monitoring

- Better manufacturer support and parts availability

A quality standby generator from a reputable manufacturer costs more upfront but delivers lower lifetime cost per operating hour through better fuel efficiency, longer service intervals, and greater reliability when it matters most.

Plan for Lifecycle Management

No generator runs forever. Engine overhaul becomes necessary after 10,000-30,000 operating hours depending on application and maintenance quality. Budget for major overhauls as part of total cost of ownership. Some facilities find it economical to replace rather than overhaul generators beyond certain age or hour thresholds, especially when newer units offer significantly better fuel economy or meet updated emissions standards.

Proactive lifecycle planning prevents emergency replacements during outages and allows you to leverage technological improvements as they emerge.

Real-World Applications: Where Diesel Generators Make a Difference

Theory is useful, but diesel generators prove their value in concrete, mission-critical applications where power interruption means financial loss, safety risks, or operational shutdown.

Data Centers and IT Infrastructure

Data centers can’t tolerate downtime. A single minute of outage can cost thousands or millions in lost revenue, compromised data, and SLA penalties. Diesel generator systems provide the backbone of data center resilience, working in tandem with UPS batteries to bridge the gap between utility failure and generator startup.

Tier III and IV data centers (as defined by the Uptime Institute) specify N+1 or 2N generator redundancy, with gensets capable of supporting full facility load for extended periods. These installations often feature multi-megawatt generator banks with sophisticated paralleling, automatic synchronization, and remote monitoring that alerts operators the instant any parameter deviates.

Healthcare Facilities

Hospitals represent perhaps the most critical application. Operating rooms, life support equipment, refrigerated medication storage, and patient monitoring systems must have uninterrupted power. Healthcare regulations mandate emergency power systems meeting specific performance criteria.

Medical facilities typically separate loads into life-safety (immediate transfer, typically within 10 seconds) and equipment (delayed transfer, up to 60 seconds). The backup power system must support both categories for the duration of any outage, which could extend for days during natural disasters.

Manufacturing and Industrial Operations

Modern manufacturing relies on precise process control. A sudden power loss can ruin batches of product, damage machinery, or create safety hazards. Industries like chemicals, food processing, pharmaceuticals, and semiconductor fabrication use diesel generators as insurance against production disruption.

Some facilities operate generators continuously as prime power in locations where grid electricity is unreliable or unavailable. In these applications, continuous power ratings and robust maintenance programs become essential.

Telecommunications and Emergency Services

Cell towers, 911 dispatch centers, police and fire stations, and emergency broadcast systems all depend on diesel generators to maintain operations when the grid fails. These installations often include extra-large fuel tanks supporting 48-72 hours of runtime without refueling.

Construction and Remote Sites

Portable diesel generator units power construction equipment, temporary lighting, and tools at job sites lacking utility infrastructure. These mobile gensets range from compact trailer-mounted 20 kW units to heavy-duty 500+ kW machines that support entire temporary facilities.

Oil and gas operations, mining sites, and remote research stations use generators as primary power sources, sometimes running continuously for years with only scheduled maintenance interruptions.

Frequently Asked Questions

Q1: How long can a diesel generator run continuously?

A1: Modern industrial diesel generators designed for continuous duty can run indefinitely with proper maintenance and periodic servicing. However, most standby generator applications involve intermittent operation. Industry practice suggests limiting continuous run time to 200-300 hours between service intervals for standby-rated units, though prime-rated and continuous-rated gensets can operate for thousands of hours between major services. The actual limit depends on the generator’s duty rating, maintenance quality, and operating conditions. Always consult your specific generator’s rating and manufacturer recommendations.

Q2: How efficient are diesel generators compared to other power sources?

A2: Diesel generators typically achieve 35-45% thermal efficiency (converting fuel energy to electrical output), with larger industrial units reaching the higher end of that range. This makes them significantly more efficient than gasoline generators (25-30%) and competitive with natural gas units (30-40%). However, grid electricity—when available—remains more cost-effective for continuous use. The value of diesel generators lies in their reliability, fuel efficiency, portability, and ability to provide power when and where grid power isn’t available or has failed.

Q3: What is the difference between standby, prime, and continuous power ratings?

A3: These ratings define how a generator can be used. Standby power rating applies to emergency backup applications where the generator operates only during utility outages, typically for limited hours per year (maybe 50-200 hours annually). Prime power rating suits applications where the generator serves as the primary power source, operating for unlimited hours with variable load (typical average 70-80% of rating). Continuous power rating defines maximum output for non-stop operation at constant load 24/7. Always match the generator rating to your intended application—using a standby-rated unit for continuous duty will void warranties and cause premature failure.

Q4: Do diesel generators require special fuel?

A4: Standard diesel generators use regular automotive diesel fuel (No. 2 diesel in the U.S., similar grades elsewhere). However, fuel quality matters significantly. Use ultra-low sulfur diesel (ULSD) in modern engines to protect emission control systems. For long-term storage in backup power system applications, add biocide and stabilizer additives to prevent microbial growth and fuel degradation. In cold climates, winter-blend diesel or additives prevent fuel gelling. Some generators can run on biodiesel blends (up to B20, 20% biodiesel), though always verify compatibility with your specific manufacturer.

Q5: How often does a diesel generator need maintenance?

A5: Maintenance frequency depends on operating hours and application. Typical schedules include: Weekly/monthly: Visual inspection, exercise cycle. Every 100-250 hours or annually: Oil and filter change, fuel filter replacement, battery check. Every 400-500 hours or every 2 years: Air filter, coolant check, belts and hoses inspection. Every 2,000-3,000 hours or 5 years: Major service including valve adjustment, injector service, comprehensive system inspection. For standby units that run infrequently, calendar intervals often trigger maintenance before hour-based intervals. Following the manufacturer’s maintenance schedule religiously is the single most important factor in generator reliability and longevity