Introduction

Let me tell you something that still keeps me up at night from my early days in the generator business. I got a call at 2 AM from a hospital facility manager—their Cummins standby generator wouldn’t start during a power outage. Lives were literally on the line. The culprit? A battery that had failed six months before its expected lifespan. That experience taught me the hard way that understanding generator battery lifespan isn’t just technical knowledge—it’s mission-critical information that can prevent catastrophic failures.

After 15 years of maintaining, troubleshooting, and optimizing hundreds of Cummins diesel generator systems across hospitals, data centers, and industrial facilities, I’ve seen every battery failure scenario imaginable. I’ve watched perfectly good batteries die prematurely from neglect, and I’ve seen well-maintained units exceed their rated lifespan by years. The difference? Knowledge and discipline.

So, how long do Cummins generator batteries typically last? The straightforward answer: 3 to 5 years for most lead-acid batteries in typical standby applications. But here’s the reality I’ve learned from the field—that’s just an average. I’ve replaced batteries at 18 months in harsh environments and seen others push past 7 years with meticulous care. The actual lifespan depends on a complex interplay of factors that most generator owners don’t fully understand.

In this comprehensive guide, I’m sharing everything I’ve learned about Cummins generator battery maintenance, lifespan optimization, and replacement strategies. Whether you’re managing a single backup unit for your business or overseeing a fleet of commercial generator systems, you’ll discover practical, field-tested insights that can save you thousands in unexpected replacement costs and, more importantly, ensure your critical power system starts when you need it most.

Understanding Generator Battery Fundamentals

Before we dive into lifespans and maintenance schedules, let’s establish the foundation. If you’re new to backup power systems or just inherited responsibility for your facility’s generator, you need to understand what these batteries actually do and why they’re so critical.

What Role Does the Battery Play in a Generator System?

Here’s something that surprises many people: your Cummins diesel generator battery doesn’t power your building—it powers the starter motor that cranks the diesel engine. Think of it exactly like your car battery. When the power goes out and your automatic transfer switch signals the generator to start, that battery needs to deliver a massive burst of electrical energy (typically 400-800 amps for a few seconds) to turn over a large diesel engine.

I’ve seen facility managers assume the battery is somehow involved in producing the generator’s output power. It’s not. Once the engine fires and reaches operating speed, the battery’s job shifts to supporting the control panel, maintaining the charging system, and standing ready for the next start cycle. This distinction matters because it explains why battery capacity testing focuses on cold cranking ability rather than sustained discharge performance.

Key Battery Terminology You Need to Know

Let me break down the terms you’ll encounter in spec sheets and maintenance discussions:

Cold Cranking Amps (CCA): The most critical specification for generator starting batteries. This number tells you how many amps the battery can deliver at 0°F for 30 seconds while maintaining at least 7.2 volts. For Cummins generators, you typically need 600-1200 CCA depending on engine size. I always spec batteries on the higher end of the manufacturer’s range—that extra cranking power becomes invaluable in cold weather and as the battery ages.

Reserve Capacity (RC): Measures how long (in minutes) the battery can sustain a 25-amp draw before voltage drops below 10.5 volts. For standby generators, RC matters less than CCA, but it’s still relevant for control panel operation during extended outages. Quality batteries typically show 120-220 minutes of reserve capacity.

Amp-Hour Rating (Ah): The total charge capacity of the battery. A 100 Ah battery can theoretically deliver 1 amp for 100 hours, or 10 amps for 10 hours. Most Cummins generator batteries range from 60-120 Ah depending on the genset size and configuration.

State of Charge (SOC): The percentage of available capacity remaining. A fully charged 12-volt lead-acid battery measures 12.6-12.8 volts at rest. Below 12.4 volts, you’re under 75% charge, and below 12.0 volts indicates serious depletion that damages battery health.

The Basic Battery Chemistry at Work

Most Cummins diesel generator installations use lead-acid battery technology—the same basic chemistry invented in 1859. Don’t let the age fool you; modern lead-acid batteries are sophisticated and proven for high-reliability applications.

Inside the battery, lead plates sit in a sulfuric acid electrolyte solution. During discharge (when cranking the engine), the acid reacts with the lead to produce electrical current, creating lead sulfate on the plates. During charging, this process reverses—the sulfate converts back to lead and acid, restoring capacity.

The key insight: this chemical conversion isn’t perfect. Each charge-discharge cycle leaves a bit more permanent sulfate buildup (battery sulfation), gradually reducing capacity. Temperature accelerates these reactions—both the useful ones and the degrading ones. This is why hot engine rooms kill batteries faster than climate-controlled environments.

Understanding this chemistry explains why battery maintenance isn’t optional. You’re managing an active chemical system, not an inert component. Sulfation, corrosion, water loss (in flooded batteries), and temperature effects are constantly working against you.

What Is the Typical Lifespan Range?

Now for the question everyone asks first: what should I realistically expect from my Cummins generator batteries?

The Industry Standard Answer

Based on manufacturer specifications and industry standards like NFPA 110 (National Fire Protection Association code for emergency power systems), here’s what you’ll typically see:

- Flooded lead-acid batteries: 3-5 years in standby service

- AGM (Absorbent Glass Mat) batteries: 4-6 years in standby service

- Sealed maintenance-free batteries: 3-5 years in standby service

- Deep cycle batteries (when used inappropriately for starting): 2-4 years

These ranges assume reasonable operating conditions—moderate ambient temperatures (60-80°F), proper charging system operation, and adherence to basic maintenance schedules.

What I’ve Actually Seen in the Field

Theory meets reality in interesting ways. Over 15 years, I’ve documented battery replacement patterns across different installations, and the variation is startling:

Shortest lifespan I’ve encountered: 14 months. This was a Cummins 150 kW unit in an outdoor enclosure in Arizona. Summer temperatures inside that enclosure exceeded 120°F regularly. The charger had failed (nobody noticed), and the batteries were chronically undercharged. They sulfated rapidly and died young.

Longest lifespan I’ve verified: 8 years, 2 months. A Cummins 60 kW unit in a climate-controlled telecommunications facility in Montana. The battery compartment maintained 68-72°F year-round. Weekly automated testing, monthly manual verification, annual battery load testing. The facility eventually replaced the batteries not because they failed, but because preventive replacement was cheaper than the risk of an unexpected failure.

💡 Key Takeaway: The difference between 14 months and 8 years isn’t luck—it’s environmental control and maintenance discipline. Your batteries will last exactly as long as you design the system to support them and as consistently as you maintain them.

Critical Factors Affecting Battery Lifespan

This section separates operators who get 3 years from batteries from those who get 6+. Understanding and controlling these factors is how you maximize your investment and minimize unexpected failures.

Temperature: The Silent Battery Killer

Let me be blunt: ambient temperature is the single most important factor determining standby generator battery life. For every 15°F increase above 77°F, battery life cuts in half. That’s not a typo—a battery rated for 5 years at 77°F will last roughly 2.5 years at 92°F and just over a year at 107°F.

I learned this lesson the expensive way early in my career. A client installed a 200 kW Cummins unit in an uninsulated equipment shed in Texas. Summer readings inside that enclosure hit 115°F. We were replacing batteries annually despite perfect maintenance otherwise. After adding ventilation and insulation to maintain sub-90°F temps, the same battery brand suddenly lasted 4+ years.

Practical steps to manage temperature:

- Measure actual battery compartment temperature, not room temperature

- Consider battery temperature compensation in your charging system

- Install ventilation in enclosed generator spaces

- For outdoor units, spec insulated enclosures with temperature management

- In hot climates, budget for more frequent replacements—it’s physics, not poor quality

Charging System Quality and Settings

A battery is only as good as the charger maintaining it. I’ve seen perfect batteries destroyed by faulty chargers, and mediocre batteries nurse along for years with excellent charging systems.

Float voltage (the constant maintenance charge when the generator isn’t running) is critical. For 12-volt lead-acid batteries:

- Too low (<13.2V): Chronic undercharge leads to sulfation and capacity loss

- Correct (13.5-13.8V): Maintains full charge without overcharging

- Too high (>14.2V): Accelerates water loss, plate corrosion, and thermal stress

I check float voltage on every maintenance visit. You’d be shocked how many intelligent battery chargers drift out of specification over time. A charger running at 14.5V will kill a battery in 18-24 months through constant overcharging.

Cycling Frequency and Depth

Standby batteries prefer to sit at full charge, occasionally delivering high-current starts. Each deep discharge cycle (draining below 50% capacity) permanently reduces lifespan.

For typical emergency power system batteries:

- Monthly test starts: Negligible impact (discharges <5%)

- Extended outages (hours to days): Moderate impact

- Frequent cycling (daily use): Severe impact—wrong battery type for the application

I once consulted for a manufacturing facility that ran their Cummins generator 3-4 hours daily for load peak shaving. They were replacing batteries every 18 months and couldn’t understand why. The solution: specify deep cycle batteries with proper cycling support, or accept the accelerated replacement schedule. Standard starting batteries aren’t designed for that service.

Maintenance Discipline

This is where most failures originate—not from worn-out batteries, but from neglected ones. Your batteries need regular attention:

Weekly checks (per generator maintenance services standards):

- Verify charger operation and voltage

- Visual inspection for corrosion, leaks, or swelling

- Check control panel for low battery alarms

Monthly operational testing:

- Exercise start (per generator service intervals)

- Monitor cranking voltage (shouldn’t drop below 10V during start)

- Document start performance trends

Quarterly detailed inspection:

- Clean terminals and cable connections

- Check electrolyte level (flooded batteries only)

- Measure individual cell voltages

- Record specific gravity readings (flooded batteries)

Annual comprehensive testing:

- Professional battery load testing

- Conductance testing to verify CCA capacity

- Battery internal resistance measurements

- Document results against baseline

The facilities with excellent battery lifespan follow these schedules religiously. The ones calling me for emergency replacements? They’re the “we’ll deal with it when it fails” crowd.

Water Quality and Electrolyte Management

For flooded lead-acid batteries, water maintenance is non-negotiable. Batteries consume water through normal charging (electrolysis), and letting cells run dry permanently damages the plates.

Use only distilled or deionized water—never tap water. Tap water minerals cause plate contamination and accelerated degradation. I’ve seen batteries fail at 2 years solely from tap water addition.

Specific gravity testing tells you the charge state and health of each cell. A fully charged cell reads 1.265-1.280 at 77°F. Variation between cells exceeding 0.050 (50 points) indicates a failing cell. This early warning often gives you months to plan replacement before outright failure.

Vibration and Mechanical Stress

Generators vibrate—that’s unavoidable. But excessive vibration loosens connections, cracks battery cases, and degrades internal plate structures.

Mount batteries properly with secure hold-downs. Check cable connections quarterly—loose terminals create resistance, heat, and eventual failure. For installations with severe vibration (mobile generators, high-vibration engines), specify AGM battery advantages include superior vibration resistance compared to flooded designs.

Load Characteristics and Starting Demands

Bigger engines need more battery capacity. Seems obvious, but I’ve encountered undersized batteries countless times—usually aftermarket replacements where someone “saved money” with insufficient CCA rating.

Match or exceed OEM battery specifications. That spec exists because engineering calculated the minimum reliable starting capacity for your specific engine, in the worst expected conditions. Undersizing by even 100 CCA can mean failed starts in cold weather or as the battery ages.

Similarly, parallel battery configuration (two 12V batteries in parallel, or two 12V in series for 24V systems) requires identical batteries—same brand, model, age, and preferably from the same production batch. Mixing old and new batteries forces the weak unit to drag down the strong one, killing both prematurely.

Battery Types and Technology Differences

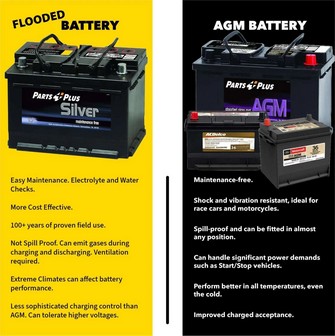

Not all generator batteries are created equal. Choosing the right type for your application and understanding the tradeoffs can add years to your battery life and improve reliability.

Flooded Lead-Acid Batteries: The Traditional Workhorse

Flooded lead-acid batteries remain the most common choice for Cummins diesel generator applications, and for good reasons—proven reliability, excellent cold-cranking performance, and competitive pricing.

How they work: Open cells filled with liquid electrolyte (sulfuric acid and water). During charging, water breaks down into hydrogen and oxygen gas, which vents to atmosphere through caps. This means water must be periodically added.

Advantages:

- Lowest cost per amp-hour and CCA

- Excellent high-current discharge capability

- Long track record in generator applications

- Easy to test and diagnose

- Can be reconditioned with equalization charging

Disadvantages:

- Requires regular water maintenance (monthly to quarterly)

- Must be mounted upright (liquid electrolyte)

- Susceptible to sulfation if left discharged

- Generates hydrogen gas during charging (ventilation required)

- Temperature-sensitive performance

When I recommend them: Cost-conscious installations with committed maintenance staff. Commercial and industrial facilities with structured PM programs. Any application where someone will actually check water levels regularly.

AGM (Absorbent Glass Mat) Batteries: The Premium Choice

AGM batteries represent the sweet spot between performance and convenience for many modern installations. Companies like Tesla Power often spec AGM batteries for their premium generator packages because they deliver excellent reliability with minimal maintenance.

How they work: Electrolyte is absorbed into fiberglass mat separators between the plates. The battery is sealed, so water can’t escape and doesn’t need addition. Internal recombination captures and reconverts gases back to water.

Advantages:

- Zero maintenance (truly sealed)

- Superior vibration resistance

- Can be mounted in any orientation

- Lower self-discharge rate (better for infrequently-used units)

- Faster recharge acceptance

- Longer service life in high-temperature environments (compared to flooded)

- No hydrogen venting concerns

Disadvantages:

- Higher initial cost (typically 40-60% more than flooded)

- Sensitive to overcharging (requires precise voltage regulation)

- Difficult to recover from deep discharge

- Cannot be serviced or reconditioned

When I recommend them: Installations with limited maintenance access. Outdoor or mobile generators with vibration concerns. Facilities without trained staff for water maintenance. Hot environments where the extra lifespan justifies the premium cost.

I recently spec’d AGM batteries for a series of Cummins units at remote cell tower sites. The extra $200 per battery paid for itself within two years by eliminating monthly maintenance visits.

Sealed Maintenance-Free Batteries: The Middle Ground

These are essentially flooded batteries with extra electrolyte reserve and special caps that minimize water loss. They’re “maintenance-free” in that they don’t need water addition under normal service, but they’re not truly sealed like AGM.

When I recommend them: Budget-conscious projects where AGM cost isn’t justified but regular water maintenance isn’t practical. Smaller residential generators where the owner wants simplicity.

The catch: Despite the “maintenance-free” label, they still need regular voltage checks and testing. And in hot climates or with charging system problems, they do eventually lose water—at which point they’re unrepairable.

Gel Cell Batteries: Rarely the Right Choice

Gel batteries use silica gel to immobilize the electrolyte. They’re excellent for deep-cycle applications (solar, RV, marine), but rarely optimal for generator starting service.

Why I don’t recommend them for Cummins generators: Lower cold-cranking capability, very sensitive to charging voltage (easily damaged by typical generator chargers), higher cost than AGM without meaningful advantages for starting applications.

I’ve seen exactly two installations where gel batteries made sense, both for generators in extreme vibration environments where AGM wasn’t sufficient. For 99% of applications, either flooded or AGM is the better choice.

Choosing the Right Type for Your Application

My decision framework:

- Mission-critical installations (hospitals, data centers, emergency services): AGM or flooded with professional maintenance

- Commercial/industrial with maintenance staff: Flooded batteries for cost efficiency

- Remote or infrequent-access sites: AGM exclusively

- Residential/small commercial: Sealed maintenance-free or AGM based on budget

- Harsh environments (extreme heat, cold, or vibration): AGM

For aftermarket generator batteries, stick with specifications from reputable manufacturers. Brands like East Penn (Deka), Johnson Controls, Exide, and Tesla Power offer quality options across all technology types.

Essential Testing Tools and Equipment

You can’t manage what you can’t measure. Here are the tools that separate guesswork from data-driven battery management systems.

Digital Multimeter: Your First Line of Defense

Every maintenance toolkit needs a quality digital multimeter. This simple tool provides the most immediate battery health indicator—voltage.

What to measure:

- Resting voltage (after 2+ hours without charge or discharge): Should read 12.6-12.8V for a healthy 12V battery

- Float voltage (while on charger): Should match spec (typically 13.5-13.8V)

- Cranking voltage (during start): Shouldn’t drop below 10.0V

I recommend meters with min/max hold function so you can capture that cranking voltage dip. Models from Fluke, Klein, or even decent Harbor Freight units work fine for generator battery testing.

Pro tip: Document your voltage readings over time. A battery that measured 12.7V last quarter but only shows 12.3V this quarter (with no load) is telling you it’s declining, even if it still starts the engine.

Figure 1: Professional digital multimeter testing showing proper probe placement on battery terminals. Regular voltage testing is the foundation of battery health monitoring.

Battery Load Tester: The Gold Standard

Battery load testing remains the definitive method for evaluating starting capacity. A load tester applies a controlled high-current discharge (typically 50% of CCA rating for 15 seconds) while monitoring voltage.

Pass/fail criteria: Voltage should remain above 9.6V under load for a 12V battery. Below that threshold indicates insufficient capacity for reliable starting.

Quality load testers from brands like Midtronics, Clore Automotive, or Schumacher range from $150-600. For facilities managing multiple generators, this investment pays for itself in prevented failures.

When to load test:

- Annually as preventive maintenance

- When voltage readings suggest decline

- Before critical usage periods (hurricane season, winter, etc.)

- After any charging system repairs

- When planning battery replacement (confirm failure before spending)

I’ve caught countless batteries that showed good voltage but failed under load testing. The voltage told me the battery could sit and hold charge; the load test told me it couldn’t deliver cranking current.

Conductance Tester: Modern Technology

Conductance testing applies a small AC signal and measures the battery’s electrical conductance, which correlates directly to available CCA. The major advantage: no heavy discharge required, so testing is faster and safer.

Units like the Midtronics MDX series are standard equipment for professional generator maintenance operations. They provide:

- CCA measurement in seconds

- Pass/fail indication against spec

- Trend analysis over multiple tests

- Safe testing of partially discharged batteries

The downside: quality units cost $800-2000. For single-generator owners, this isn’t cost-effective. For service companies or multi-unit facilities, it’s essential.

Hydrometer: Old School Still Works

For flooded lead-acid batteries, a hydrometer measures electrolyte specific gravity—the density of the acid solution relative to water. This directly indicates state of charge and cell health.

What readings mean:

- 1.265-1.280: Fully charged

- 1.230-1.250: 75% charged

- 1.190-1.210: 50% charged

- Below 1.190: Discharged (sulfation damage risk)

- Variation >0.050 between cells: Failing cell

Temperature affects readings, so quality hydrometers include temperature compensation scales. I prefer models with built-in thermometers.

Cost: $10-30. Every facility with flooded batteries should have one.

Battery Management and Monitoring Systems

For critical installations, consider remote battery monitoring integrated with your generator control system. These systems continuously track:

- Voltage and charging current

- Temperature

- State of charge trends

- Charge/discharge cycles

- Predictive failure warnings

Manufacturers like Battery Management Systems (BMS) and PowerShield offer units ranging from $200-2000 depending on features. The value: early warning of problems before they become failures.

I installed these on a 10-generator hospital system. The monitoring caught a failed charger within hours, preventing what would have been a $5,000 emergency battery replacement during a subsequent power outage.

Thermal Imaging Camera: The Secret Weapon

Here’s a tool most people don’t think about for battery service: infrared thermal imaging. Hot spots on terminals, cables, or battery cases indicate resistance problems that lead to failures.

I’ve found loose connections, internal cell failures, and charging system problems using a thermal camera that weren’t obvious from voltage testing. Models like the FLIR E4 or Seek Thermal cameras ($200-500) provide invaluable diagnostic capability beyond batteries—they’re useful across your entire facility.

Building Your Testing Toolkit

Minimum viable toolkit ($50-100):

- Digital multimeter

- Hydrometer (for flooded batteries)

- Battery terminal cleaner

- Safety glasses and gloves

Professional toolkit ($400-800):

- Quality multimeter with min/max function

- Battery load tester (200-1000 CCA range)

- Hydrometer with thermometer

- Terminal cleaning tools

- Battery post puller

- Thermal imaging camera

Service company / multi-unit facility ($2000-4000):

- Professional conductance tester

- Advanced load tester with printer

- Thermal imaging camera

- Battery management monitoring system

- Complete tool set for all battery services

How Batteries Relate to Your Generator System

Your battery doesn’t work in isolation—it’s part of an integrated generator system. Understanding these relationships helps you diagnose problems and optimize performance.

The Charging System Partnership

Your generator’s charging system (alternator and voltage regulator) is the battery’s life support. Even a perfect battery will fail if the charging system can’t maintain it properly.

Key relationships:

- Alternator output: Must exceed all electrical loads plus battery charging demands. Undersized alternators can’t maintain batteries during extended runtime.

- Voltage regulation: Controls float and boost charging voltages. Drift in regulation settings kills batteries faster than anything else except heat.

- Charge acceptance rate: Batteries absorb charge at different rates depending on type, age, and temperature. The charging system must accommodate this.

I diagnose a charging system problem at least twice as often as an actual battery failure. The symptoms look identical—weak cranking, low voltage, failed starts—but throwing new batteries at a bad charger just destroys the new batteries.

Battery Banks and Parallel Configurations

Larger generators often use battery banks—multiple batteries connected to increase capacity. This introduces complexity:

Series connection (24V systems): Two 12V batteries in series provide 24 volts. Each battery must carry the full current, so one weak battery limits the entire system.

Parallel connection (increased capacity): Multiple 12V batteries in parallel increase amp-hour capacity and CCA. But mismatched batteries (different ages, capacities, or states of health) create imbalanced charging and discharging, killing all batteries prematurely.

Critical rule: When replacing batteries in a bank, replace all batteries simultaneously with identical units from the same production batch. Never mix old and new batteries in parallel.

Engine Size and Starting Requirements

Bigger engines need more battery capacity—straightforward physics. But it’s not just about cranking amps:

- Cold cranking: Oil viscosity increases dramatically at low temperatures, requiring 2-3x normal cranking current

- Compression ratio: Diesel engines have higher compression than gasoline, requiring more starting power

- Starting aids: Block heaters, glow plugs, and ether starting systems draw battery power before and during cranking

Match your battery CCA to the engine manufacturer’s specification with a 20-30% safety margin. This ensures reliable starting throughout the battery’s life as capacity naturally declines.

Control Systems and Parasitic Loads

Modern generator control panels draw continuous power even when the unit isn’t running:

- Digital displays: 50-200 mA

- Network monitoring: 100-300 mA

- Leak detection systems: 50-150 mA

- Battery charger overhead: 50-100 mA

These parasitic loads add up. A generator with 300 mA of parasitic draw will discharge a 100 Ah battery from full charge to 50% (damaged territory) in just 13-14 days if the charger fails.

This is why weekly charger verification matters—a failed charger combined with parasitic loads kills batteries in weeks, not months.

Proven Strategies to Maximize Battery Life

Here’s where theory becomes practice. These strategies come directly from installations I manage that consistently achieve 5-7 year battery lifespans.

Strategy 1: Temperature Management Above All Else

I’ll say it again because it’s that important: control temperature, extend life. My most successful installations all share one trait—battery compartment temperature below 85°F year-round.

Actionable steps:

- Install a thermometer in the battery compartment (not the room—the actual battery space)

- For outdoor enclosures, add insulation and ventilation fans triggered at 80°F

- For indoor installations, don’t locate generators in equipment rooms with poor climate control

- Consider battery compartment cooling for high-heat environments

- Use temperature-compensated charging to adjust float voltage for ambient conditions

A $200 ventilation fan investment can double battery life in hot climates. The math is compelling—that fan pays for itself within a single avoided early replacement.

Figure 2: Proper battery installation showing secure mounting and accessible terminals. Note the clean environment and organized cable routing that facilitates maintenance.

Strategy 2: Implement Rigorous Maintenance Schedules

Consistency beats intensity. I’ve seen mediocre battery types outlast premium units solely because someone actually followed the maintenance schedule.

My proven schedule:

Weekly (5 minutes):

- Record float voltage from control panel or at battery terminals

- Visual inspection (corrosion, leaks, damage)

- Verify charger indicator lights

Monthly (15 minutes):

- Exercise run (20-30 minutes under load)

- Measure cranking voltage during start

- Check water level (flooded batteries)

- Clean any visible corrosion

Quarterly (30 minutes):

- Detailed terminal cleaning and coating

- Torque-check all battery connections

- Measure and record individual cell voltages

- Specific gravity testing (flooded batteries)

Annually (1-2 hours):

- Professional load testing or conductance testing

- Complete charging system evaluation

- Document all measurements against baseline

- Review and adjust maintenance schedule based on trends

Battery replacement intervals should be data-driven. I replace batteries when testing shows CCA below 80% of rating, not based solely on age.

Strategy 3: Optimize Charging System Performance

Your charger determines how long batteries last. Verify and maintain it obsessively.

Critical checks:

- Float voltage accuracy: Should be 13.5-13.8V for standard lead-acid, 13.6-13.9V for AGM. Check monthly.

- Equalization charging (flooded batteries only): Periodic controlled overcharge (14.4-15V for several hours) that reverses sulfation. Schedule quarterly for batteries in float service.

- Charging current capacity: Must fully recharge batteries within 24 hours of a typical start cycle

- Temperature compensation: Quality chargers adjust voltage based on battery temperature. Verify this works.

Figure 3: Professional technician conducting generator battery service. Regular hands-on maintenance by trained personnel significantly extends battery operational life.

Strategy 4: Exercise Your Generator Regularly

Paradoxically, batteries last longer with regular use than sitting idle. Monthly exercise runs provide benefits:

- Prevents sulfation from extended float service

- Identifies weak batteries before emergencies

- Maintains electrolyte mixing (flooded batteries)

- Verifies charging system restores full charge

- Tests the complete starting and running system

Run for at least 30 minutes at 50-75% load. Brief no-load starts don’t accomplish these goals and waste fuel.

Strategy 5: Proper Installation Practices

Many battery problems start at installation. Get these fundamentals right:

Cable sizing: Undersized cables create voltage drop and resistance heating. Follow NEC standards minimum—I typically upsize by one gauge.

Terminal connections: Clean, tight, corrosion-protected. Use proper terminal protector spray or di-electric grease. Torque to specification.

Mounting and securing: Batteries must be firmly held. Vibration and movement destroy internal structures. Use appropriate battery hold-down hardware.

Ventilation: Batteries generate hydrogen during charging. Ensure adequate ventilation to prevent explosive gas accumulation, especially in enclosed spaces.

Strategy 6: Intelligent Battery Selection

The best maintenance program can’t overcome the wrong battery choice. Consider your specific needs:

For infrequent-access sites: AGM batteries exclusively. The maintenance-free operation and longer life justify the premium cost.

For high-temperature environments: AGM again, or budget for more frequent flooded battery replacement. Don’t kid yourself that maintenance will overcome physics.

For cost-conscious installations with staff: Quality flooded batteries with disciplined maintenance provide excellent value.

For critical applications: Overspec capacity by 20-30%. The extra CCA provides safety margin as batteries age.

Brands matter. I’ve had excellent results with East Penn (Deka), Exide, and Tesla Power batteries. The cheapest battery is rarely the best value when you factor in lifespan and reliability.

Strategy 7: Document Everything

Data reveals trends before failures occur. I maintain a simple spreadsheet for each generator:

- Installation date and battery specifications

- Monthly voltage readings

- Quarterly cell voltage and specific gravity

- Annual load test results

- All maintenance performed

- Any anomalies or issues

This documentation has saved facilities thousands by catching degradation trends 6-12 months before outright failure, allowing planned replacement instead of emergency service.

Strategy 8: Proactive Replacement

The most expensive battery failure is the one that happens during a power outage. Once batteries reach 4-5 years (3-4 in harsh environments), I recommend proactive replacement even if testing shows acceptable performance.

The math: An emergency battery replacement during a crisis costs 3-5x normal replacement cost (emergency service rates, rush shipping, potential downtime consequences). Scheduled replacement at year 4-5 avoids this risk entirely.

For mission-critical installations, I spec battery warranty coverage requirements and replacement schedules that ensure batteries never exceed 70% of rated lifespan before replacement.

Figure 4: Visual comparison showing the structural differences between flooded lead-acid (left) and AGM batteries (right). Understanding these differences helps in selecting the optimal battery type for your specific application.

Cummins vs Other Manufacturers: Battery System Comparison

How do Cummins generator battery systems stack up against competitors? After servicing units from all major manufacturers, here’s my honest assessment.

Cummins: The Gold Standard

Cummins maintains tight specifications and excellent documentation for battery requirements across their product line. OEM battery specifications are clearly stated in installation manuals, and their charging systems are generally well-engineered and reliable.

Strengths:

- Clear battery sizing guidelines by model

- Quality voltage regulators with good temperature compensation

- Excellent service network and parts availability

- Batteries easily accessible for maintenance

- Strong technical support for troubleshooting

Battery lifespan expectations: 4-6 years in properly maintained installations (matches or exceeds industry average).

Caterpillar: Equally Robust

Caterpillar generators feature similarly rigorous battery specifications and high-quality charging systems. Their industrial heritage shows in robust battery mounting and electrical systems.

Comparison to Cummins: Effectively equivalent. Battery life depends more on maintenance and environment than brand choice between these two manufacturers.

Kohler: Residential to Industrial Range

Kohler’s diverse product line means battery system quality varies significantly. Their commercial/industrial units rival Cummins; residential units sometimes use more basic charging systems.

Battery lifespan: 3-5 years typical. Their residential units often see shorter lifespan due to less sophisticated charging and typically less rigorous maintenance.

Generac: Volume Leader with Caveats

Generac dominates the residential market with cost-effective units. Battery systems are adequate but not over-engineered.

Observations from the field: I see more charging system issues with Generac units than with Cummins or Caterpillar. Battery life often skews toward the lower end of the range (3-4 years) unless maintenance is exceptional.

That said: Their newer commercial units have improved significantly. Don’t dismiss them based on older residential equipment experience.

The Real Difference: Charging System Quality

The primary battery life differentiator across manufacturers isn’t the batteries themselves—most use similar brands (Interstate, Deka, Exide). It’s the charging system:

- Premium brands (Cummins, Caterpillar): Better voltage regulation, temperature compensation, and overall electrical system design

- Value brands: More basic chargers that work but offer less precision and fewer protective features

A quality aftermarket intelligent battery charger can significantly improve battery life on any manufacturer’s unit.

Battery Replacement Cost Comparison

Based on current market rates for typical 100 kW class generators:

- Cummins OEM batteries: $300-500 per battery

- Caterpillar OEM batteries: $320-520 per battery

- Kohler OEM batteries: $250-450 per battery

- Generac OEM batteries: $200-400 per battery

- Quality aftermarket (Deka, Exide, Tesla Power): $180-380 per battery

OEM batteries offer guaranteed compatibility but command premium pricing. Quality aftermarket batteries matching OEM specifications provide excellent value.

My Recommendation

For new installations, Cummins and Caterpillar offer the most refined battery and charging systems. For existing equipment, any manufacturer’s generator can achieve excellent battery life with proper maintenance and, if needed, charging system upgrades.

Focus less on the generator brand and more on the factors you control: temperature management, maintenance discipline, and appropriate battery selection.

Real-World Case Studies from My Experience

Theory is great, but let me share actual installations that illustrate these principles in action.

Case Study 1: The Manufacturing Facility Turnaround

Situation: A 250 kW Cummins unit at a textile manufacturing plant was eating batteries—replacements every 18-24 months. Management was frustrated and considering a complete generator replacement.

Investigation findings:

- Battery compartment temperature: 105-118°F during summer (generator room had poor ventilation)

- Float voltage: 14.3V (should be 13.6-13.8V)

- No maintenance logs—batteries got water “when someone remembered”

- Using cheap aftermarket batteries 100 CCA below OEM spec

Solution implemented:

- Installed ventilation system with thermostat-controlled fans ($800)

- Replaced voltage regulator and calibrated charging system ($350)

- Established weekly maintenance schedule with plant electrician

- Upgraded to OEM-spec AGM batteries ($600 vs. $400 for cheap flooded)

Results: Battery life jumped to 5.5+ years. The current set is at 5 years and still testing at 95% capacity. Total investment of $1,750 will save approximately $3,000 over ten years in reduced battery replacement frequency, plus eliminated emergency service calls.

Case Study 2: The Data Center Success Story

Situation: Critical data center with four 500 kW Cummins generators requiring maximum reliability. No battery failures acceptable.

Approach: Proactive management from installation:

- Climate-controlled generator room maintaining 70-75°F year-round

- Premium AGM batteries spec’d with 30% CCA margin above OEM minimum

- Weekly automated monitoring with alerts for any voltage deviation

- Quarterly professional maintenance including conductance testing

- Scheduled replacement at 5 years regardless of test results

Results: Zero battery-related failures in 12 years of operation. Average battery lifespan: 5 years (by design—proactive replacement). Contrast with industry data showing 15-20% of generator failures are battery-related.

Cost analysis: Higher initial investment (premium batteries, monitoring, scheduled replacement) costs roughly 40% more than reactive approach. But zero downtime in a data center environment where one minute of failure costs tens of thousands? Priceless.

Case Study 3: The Remote Cell Tower Optimization

Situation: Telecommunications company with 35 Cummins generators at remote cell towers. Battery replacement required expensive site visits (3-4 hours round trip, often in difficult terrain). Previous approach: wait for failure, then emergency replacement.

Analysis: Annual emergency replacements: 8-12 sites. Average cost per emergency call: $1,200 (battery + labor + travel). Annual cost: $10,000-14,000.

Solution:

- Switched all sites to AGM batteries (eliminated water maintenance visits)

- Implemented remote monitoring on all units ($6,000 investment)

- Established 4-year scheduled replacement program

- Consolidated replacements into planned maintenance routes (4-6 sites per trip)

Results after 3 years:

- Emergency battery calls dropped from 8-12/year to 1-2/year

- Scheduled replacement cost per site: $420 (bulk purchasing, efficient routing)

- Annual battery program cost: $4,000-5,000 (roughly half previous cost)

- Improved generator availability from 97.2% to 99.7%

The remote monitoring system paid for itself in the first year through eliminated emergency calls.

Frequently Asked Questions

1. Can I use a car battery in my Cummins generator?

Technically possible, but I strongly advise against it. Generator starting batteries are designed for standby service—long periods at full charge with occasional high-current discharge. Car batteries are optimized for daily starting cycles and continuous alternator charging while driving.

The key differences: Generator batteries typically have thicker plates for longevity in float service and higher reserve capacity for control panel operation. Car batteries prioritize cranking power and rapid recharge but don’t tolerate extended float charging as well.

I’ve seen facilities try this “cost-saving” approach. The car batteries typically fail within 12-18 months—half the lifespan of proper generator batteries. Use the right tool for the job. Quality industrial generator batteries from manufacturers like Deka or Tesla Power are specifically engineered for standby power applications.

2. How do I know when my generator batteries need replacement?

Don’t wait for failure. Watch for these warning signs:

Immediate replacement indicators:

- Won’t start the generator (confirmed not a charger or connection issue)

- Load test shows voltage below 9.6V under 50% CCA load

- Conductance test shows CCA below 80% of rating

- Physical damage: swelling, cracks, leaks

- Sulfation visible on plates (in flooded batteries)

Plan replacement soon:

- Age 4-5 years (3-4 in hot climates)

- Voltage readings declining over successive tests

- Specific gravity variation >0.050 between cells

- Slow cranking even with full charge

- Frequent need for water addition (flooded batteries)

- Resting voltage consistently below 12.4V

Proactive replacement strategy: I recommend scheduled replacement at 4-5 years for critical applications, regardless of test results. The cost of planned replacement is far less than emergency service during a power outage.

3. What’s the difference between 12V and 24V battery systems?

This comes down to starting power requirements and system design preferences:

12V systems (most common for smaller generators):

- Single 12V battery or multiple 12V batteries in parallel

- Typical for generators under 150 kW

- Easier to source batteries

- Lower starter motor cost

- Simpler troubleshooting

24V systems (larger generators):

- Two 12V batteries in series to create 24V

- Used for generators over 150-200 kW typically

- Provides same cranking power with lower current (half the amperage of 12V for same wattage)

- Reduces cable size requirements

- Better for very large diesel engines

The voltage system is determined by your generator’s starter motor specification—you can’t choose one or the other. Match the battery configuration to what your generator requires. For 24V systems, remember to replace both batteries simultaneously even if only one tests bad.

4. How often should I check my generator batteries?

The generator maintenance services industry standard, aligned with NFPA 110 requirements for emergency power systems:

Weekly (5 minutes): Check charger voltage and look for obvious problems (corrosion, leaks, loose connections). This is non-negotiable for critical applications.

Monthly (15-20 minutes): Exercise run with load testing plus detailed visual inspection. Check water levels on flooded batteries. Measure cranking voltage during start.

Quarterly (30 minutes): Clean terminals, check all connections for tightness, measure individual cell voltages, perform specific gravity testing (flooded batteries).

Annually (1-2 hours): Professional load testing or conductance testing, complete charging system evaluation, documentation of all readings.

This schedule applies to standby generator battery life in commercial/industrial applications. Residential installations can often extend intervals slightly (bi-weekly instead of weekly checks), but never skip the monthly exercise and inspection.

For critical power supply batteries in hospitals, data centers, or emergency services, I actually recommend automated monitoring systems that provide continuous surveillance rather than relying solely on periodic manual checks.

5. Are AGM batteries worth the extra cost for generator applications?

In my experience: sometimes yes, sometimes no. It depends on your specific situation.

When AGM batteries are absolutely worth it:

- Remote or difficult-access installations (eliminates maintenance visits)

- Hot environments (superior heat tolerance extends life)

- Installations without trained maintenance staff

- High-vibration applications

- Any installation where someone won’t reliably maintain flooded batteries

When flooded batteries make more sense:

- Facilities with dedicated maintenance staff and procedures

- Budget-constrained projects with committed maintenance

- Applications where the battery is easily accessible

- Installations with good temperature control

Run the numbers: AGM batteries cost 40-60% more initially but last 20-30% longer and eliminate maintenance labor. For a remote site where a maintenance visit costs $200 in labor and travel, AGM pays for itself in eliminated visits. For an in-house facility where your electrician checks the generator weekly anyway, flooded batteries offer better value.

I spec AGM batteries for about 60% of my installations based on site-specific factors. The remaining 40% get quality flooded batteries with proper maintenance protocols.

[TODO:SECTION order=11 id=”references” title=”References and Resources” budget=”100-150″]