Your generator’s kilowatt rating isn’t just a number—it’s your risk posture, OPEX curve, and uptime insurance policy.

Introduction: From Grid Anxiety to Power Strategy

The world is electrifying fast—and unpredictably. From AI-heavy data centers to electrified factories and smart hospitals, the cost of downtime has soared. Selecting the right Cummins diesel generator set by power rating is now a board-level decision. Get it wrong and you’ll overpay on fuel, fail on emissions, or worse—trip breakers when you need power most. Get it right and you’ll balance resilience, cost, and compliance for the next decade.

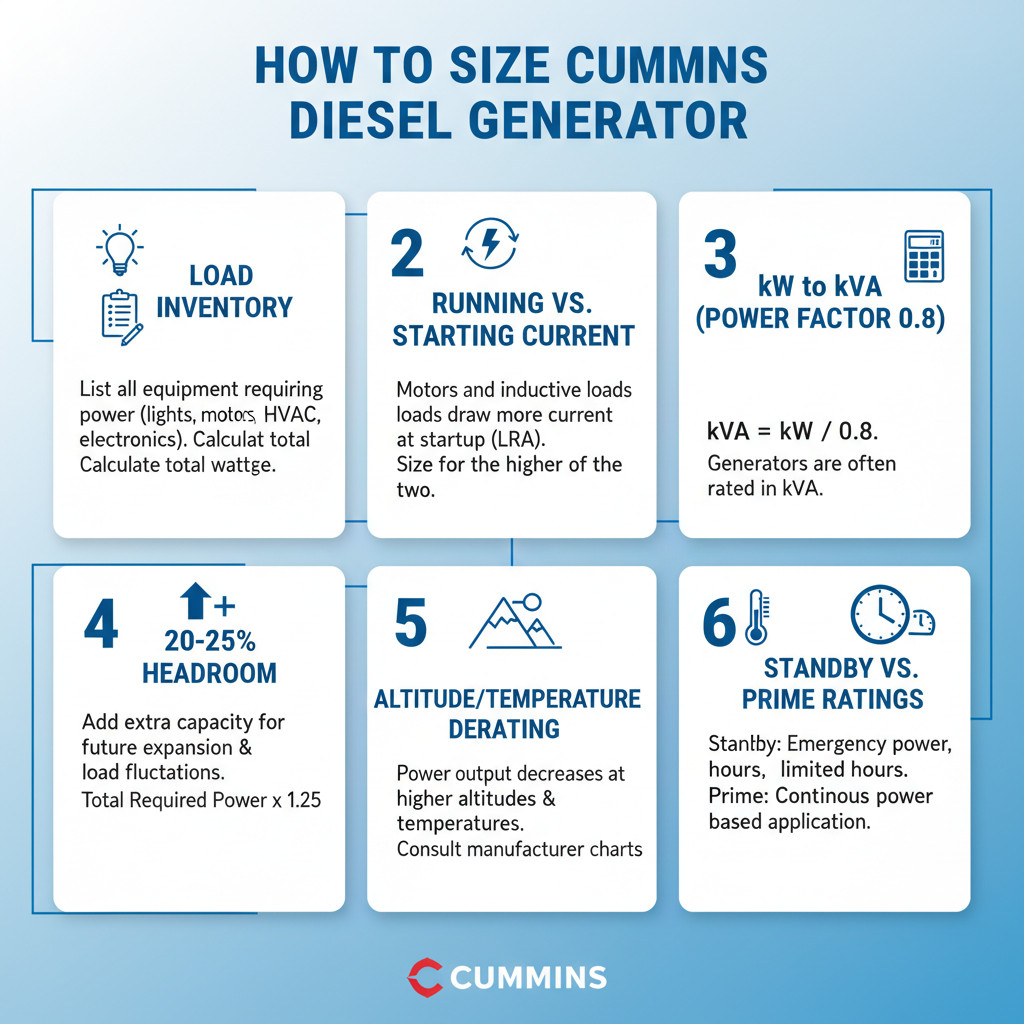

The Genesis of Generator Sizing: From kW to kVA and Real Loads

Proper sizing starts with load reality, not catalog wish lists.

- Inventory the load (motors, HVAC, UPS, compressors, elevators, pumps) and map starting vs running amps.

- Account for inrush: Motors can draw 3–7x running current at start; sequencing and soft starters change the game.

- Convert kW↔kVA: Use power factor (pf). For most industrial sites pf≈0.8; kVA = kW / pf.

- Headroom: Add 20–25% for growth and transients.

- Derate for altitude/temperature; hot, high sites lose output.

- Duty rating: Prime vs Standby vs Continuous—match to use case.

Data Point: The diesel generator market is projected to reach $23.4B by 2029 at ~5.4% CAGR, as critical industries standardize rigorous sizing and redundancy strategies.

To go deeper, many buyers consult vendor tools and experts. For mid-market and enterprise procurement, we recommend exploring [industrial generator reliability] resources for planning checklists and case-led insights.

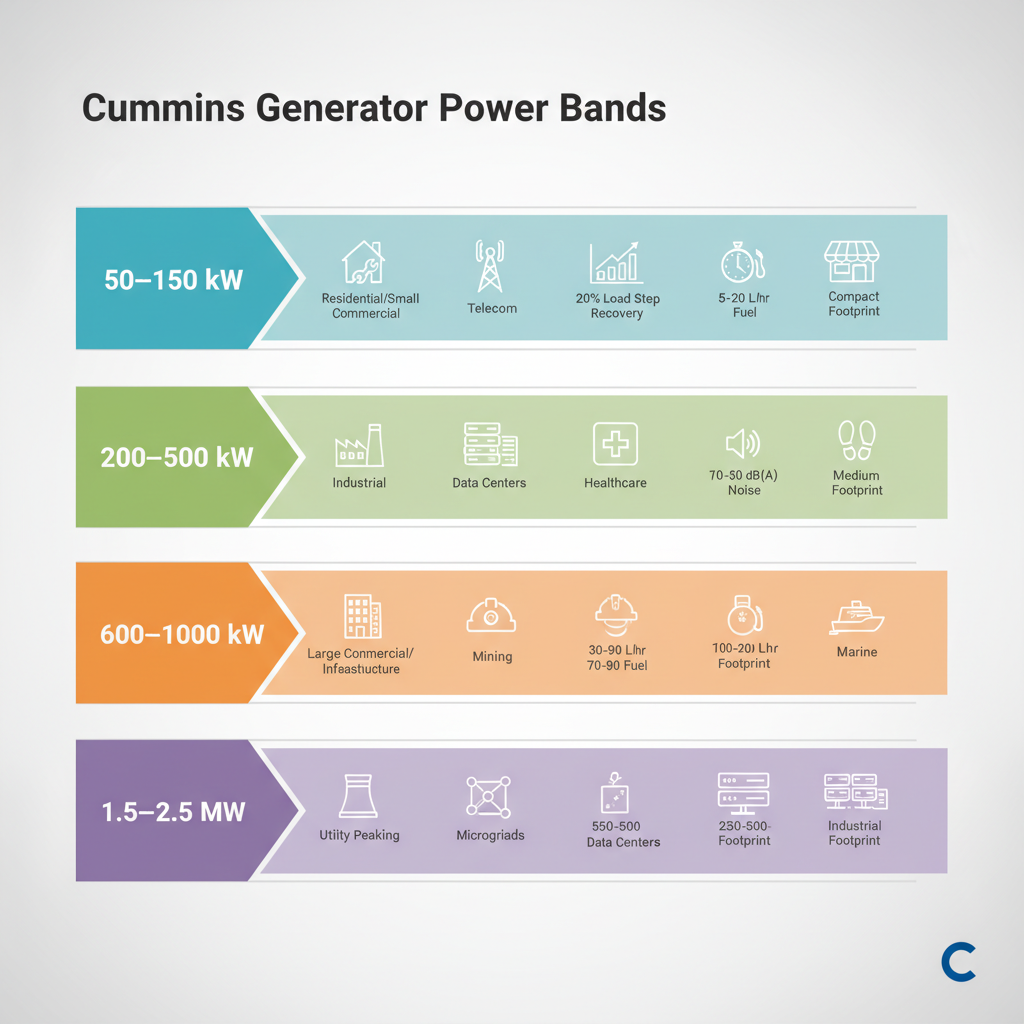

Power Bands, Different Behaviors: 50–150 kW | 200–500 kW | 600–1000 kW | 1.5–2.5 MW

Each band behaves differently under load steps, harmonics, and operational realities.

50–150 kW: SMBs, Clinics, Retail, Small Manufacturing

- Typical loads: lighting, POS, small chillers, air compressors, IT closets.

- What matters:

- Transient recovery on 30–50% load steps (elevators/HVAC kick-in).

- Noise and footprint for urban sites.

- Fuel curve at 40–60% loading; avoid chronic light-loading (wet stacking risk).

- Buyer tip: Right-size to run at 60–80% during events; add ATS with staged start for motor-heavy sites.

200–500 kW: Mid-Size Plants, Hotels, Warehouses, Campus Buildings

- Typical loads: larger AHUs, production lines, refrigeration racks, lifts, fire pumps.

- What matters:

- Step-load handling (e.g., 40% step with <3 sec recovery).

- Selective coordination with switchgear and upstream protection.

- Fuel efficiency at 70–80% loading and emissions package options.

- Buyer tip: Consider parallel-ready switchgear to add a second unit later—keeps CAPEX lean and uptime high.

600–1000 kW: Hospitals, Tier 2/3 Data Centers, Large Manufacturing

- Typical loads: ICU, ORs, imaging, chillers, process motors, UPS w/ non-linear draw.

- What matters:

- Harmonics from UPS/VFDs; ensure alternator sizing and AVR settings.

- Load acceptance: 50–60% step with tight frequency/voltage recovery.

- Redundancy: N+1/N+N paralleling to hit SLA uptime targets.

- Buyer tip: Engineer load sequencing and black-start procedures; test quarterly under realistic profiles.

1.5–2.5 MW: Campuses, Tier 3/4 Data Centers, Heavy Industry

- Typical loads: central plant chillers, hyperscale UPS, mining/process lines.

- What matters:

- Grid-forming controls and island mode stability.

- Fuel logistics for multi-day outages; dual-day tanks, polishing.

- Compliance: tiered emissions (e.g., Tier 4 Final where required) and acoustic packages.

- Buyer tip: Model transient stability with digital twins; validate step-loads with FAT/SAT witnessed tests.

Bottom line: Different kW classes are different animals—treat them as such.

Case Studies: What a 250 kW vs. an 800 kW Cummins Really Changes

Case A: 250 kW for a Mid-Size Factory

- Storm-prone region, frequent sags/outages.

- Mix of induction motors, compressors, and PLC lines.

- Outcome: Sequenced motor starts + 25% headroom eliminated nuisance trips; annual downtime fell by 72%.

Case B: 800 kW for a General Hospital

- Critical loads: ICU, ORs, MRI/CT, central plant.

- Outcome: N+1 architecture with paralleling switchgear; passed 60% step-load acceptance in <10 sec; compliance met for life-safety.

Insight: Stepping up in power class isn’t linear—controls, alternator sizing, and switchgear strategy scale with risk, not just kW.

Multi-Layer Impact: Users, Competitors, Supply Chains, Global Markets

- End Users:

- SMBs benefit from right-sized 50–150 kW units with smart ATS.

- Enterprises deploy 600 kW–2.5 MW arrays for SLA-backed uptime.

- Competitors:

- Vendors differentiate with digital monitoring, harmonic tolerance, and fast transient recovery.

- Supply Chain:

- Alternators, controllers, aftertreatment, and switchgear lead times dominate project schedules.

- Regional emissions kits affect availability and CAPEX.

- Global Market:

- Diesel generator market will surpass $23.4B by 2029; demand surges in APAC for manufacturing and public infrastructure.

For procurement roadmaps, see [diesel backup power generator] checklists and price benchmarks, or consult a [diesel generator supplier China] for regional lead times and compliance.

A Practical Sizing Framework (5 Steps)

- Define critical vs. non-critical loads; tag motor starting currents and UPS rectifier sizes.

- Choose duty rating (Standby/Prime/Continuous) aligned to outage profile.

- Model transients for biggest motor/UPS steps; validate alternator sizing.

- Select emissions + acoustics by jurisdiction; pre-check permits.

- Plan for O&M: test intervals, fuel quality program, parts coverage.

- Tools: vendor sizing software, harmonic studies, FAT/SAT protocols.

- Partnerships: EPCs, MEP consultants, and [industrial diesel power solutions] integrators.

Pro Tip: Keep generators loaded between 60–80% during operation for best fuel efficiency and engine health.

Conclusion: Design for the Outage You Can’t Afford

Right-sizing Cummins by kW is less about nameplates and more about risk. Treat power selection as a portfolio decision—balancing uptime, cost, and compliance across scenarios. For mid-market deployments, 200–500 kW often hits the sweet spot; for mission-critical campuses, 600 kW–2.5 MW with N+1/N+N is the new normal.

Final Question: Which outage scenario would break your business—and have you modeled the generator that prevents it?

Common FAQ: Choosing Cummins Generator Power Ratings

- How do I convert kW to kVA for sizing?

Use kVA = kW / pf; assume pf≈0.8 if unknown. - What’s the best loading range for diesel generators?

60–80% of rated capacity in steady operation. - Standby vs. Prime vs. Continuous—what’s the difference?

Standby: emergencies; Prime: variable load extended use; Continuous: constant base load. - How do altitude and heat affect rating?

Expect derating above ~1000m and in high ambient temperatures per OEM tables. - Can I parallel smaller units instead of one big set?

Yes—improves redundancy and maintenance flexibility; evaluate switchgear cost.

References

- MarketsandMarkets via GlobeNewswire. “Diesel Generator Market worth $23.4 Billion by 2029 …” https://www.globenewswire.com/news-release/2024/12/03/2990219/0/en/Diesel-Generator-Market-worth-23-4-Billion-by-2029-Globally-at-a-CAGR-of-5-4-says-MarketsandMarkets.html

- Fortune Business Insights. “Diesel Generator Market Size, Share …” https://www.fortunebusinessinsights.com/press-release/diesel-generator-market-9677

- Cummins Power Systems. “Generator Sizing Guidelines” (OEM application notes)

- IEEE Std 446 (Brown Book). “Recommended Practice for Emergency and Standby Power Systems for Industrial and Commercial Applications.”

- ASHRAE Handbook – HVAC Applications (healthcare/data centers load profiles)