When the lights go out at a hospital, data center, or manufacturing plant, every second counts. Mission-critical power systems can mean the difference between smooth operations and catastrophic downtime costs. For businesses evaluating backup power solutions, China Cummins generator sets have emerged as a compelling choice—combining proven engineering with cost-effective manufacturing.

But what makes these gensets reliable enough for 24/7 industrial operations? The answer lies in a unique combination of factors: Cummins’ global engineering standards, China’s advanced manufacturing capabilities, and decades of field-proven performance across demanding applications. From data centers requiring N+1 redundancy to construction sites needing continuous-duty power, these diesel generator systems deliver the uptime your business can’t afford to lose.

In this comprehensive guide, we’ll explore the technical specifications, real-world applications, and practical considerations that make China Cummins generator sets a trusted solution for industrial power backup. Whether you’re sizing a system for a new facility or evaluating alternatives to your current setup, you’ll find actionable insights backed by specifications, standards, and deployment experience.

What Are China Cummins Generator Sets?

A Cummins generator set (or genset) is an integrated power system that combines three essential components: a Cummins diesel engine, an alternator (typically from brands like Stamford or Marathon), and a control system—all designed, manufactured, and tested as a cohesive unit. Unlike piecemeal assemblies where components from different manufacturers are bolted together, Cummins engineers these systems from the ground up to work in harmony.

China-manufactured Cummins gensets leverage engines produced at facilities like Chongqing Cummins Engine Company (CCEC), which manufactures the K-series and QSK-series engines under Cummins’ global quality standards. These aren’t “knock-offs” or locally modified designs—they’re genuine Cummins products built to the same specifications you’d find in units assembled anywhere else in the world.

The term “China Cummins generator sets” specifically refers to complete power systems where the Cummins engine (often CCEC-built), alternator, control panel, cooling system, and enclosure are integrated by manufacturers in China. These gensets span power outputs from roughly 15 kVA for small commercial applications up to 3,750 kVA (3.75 MW) for large industrial installations. Popular models include units powered by the KTA19 (450-700 hp), KTA38 (925-1,100 hp), and newer high-density platforms like the QSK60 series.

What sets these systems apart is vertical integration. Cummins doesn’t just supply engines—they engineer the alternator, design the control architecture, specify cooling requirements, and validate the entire package through rigorous testing protocols. When you buy a Cummins genset from a Chinese manufacturer, you’re getting a system backed by global engineering standards but benefiting from China’s manufacturing scale and cost efficiencies.

Technical Specifications and Performance Capabilities

When evaluating Cummins genset specifications, understanding the numbers behind the nameplate matters. Let’s break down what you’ll typically see in the data sheets and what it means for your operation.

Power Output Ranges and Engine Platforms

China-manufactured Cummins gensets commonly use CCEC engine platforms across several power bands:

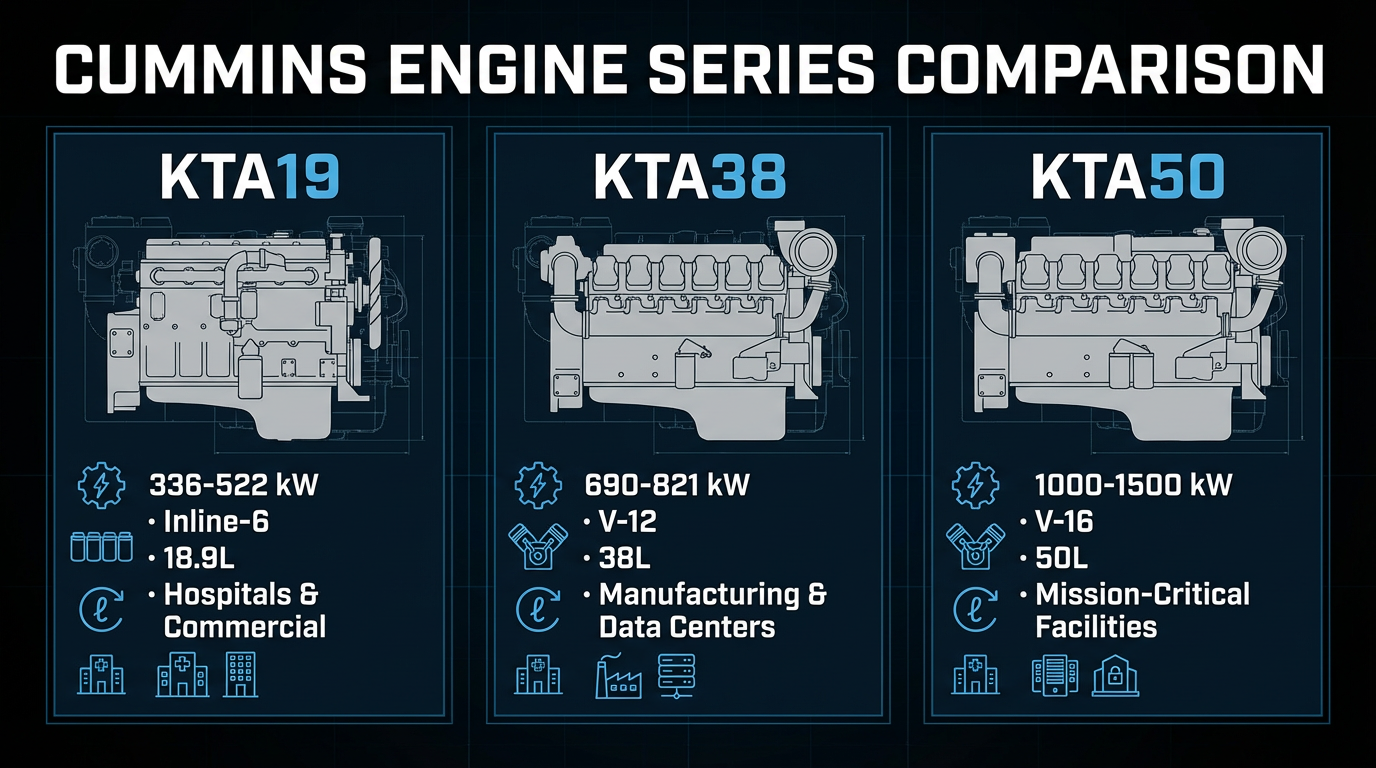

KTA19 Series (18.9L, inline-6, turbocharged)

- Prime power: 336-522 kW (450-700 hp)

- Configuration: PT fuel system with multiple intercooling options

- Common genset ratings: 400-500 kW prime, 440-550 kW standby

- Best for: Mid-size industrial facilities, hospitals, commercial buildings

KTA38 Series (38L, V12, turbocharged)

- Prime power: 690-821 kW (925-1,100 hp)

- Generator duty (G-Drive) ratings: 741-923 kW prime, 816-1,012 kW standby (50/60 Hz)

- Configuration: Jacket-water aftercooling, step timing control

- Best for: Large manufacturing plants, data centers, heavy industrial applications

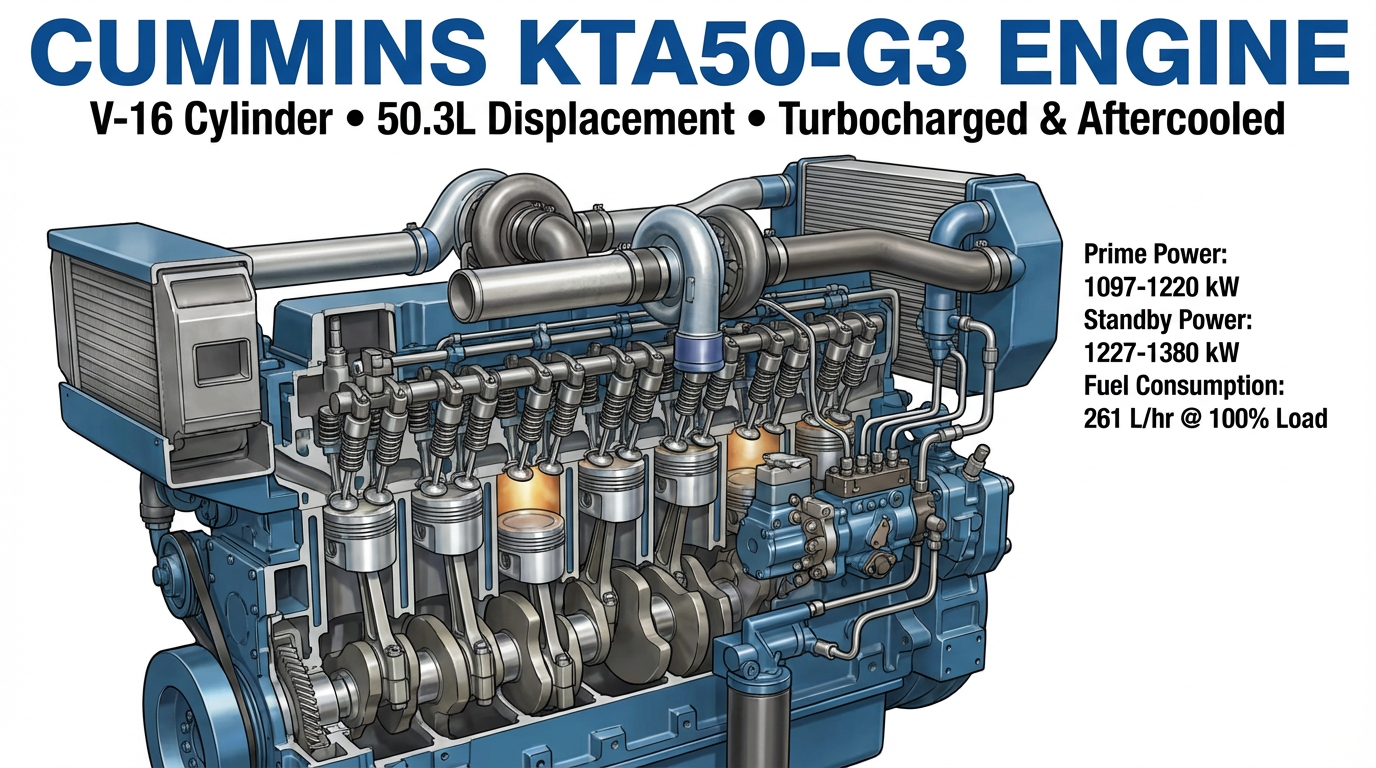

KTA50 Series (50L, V16)

- Prime power: 1,000-1,500 kW range

- Typical genset package: 1,250 kW prime / 1,375 kW standby

- Best for: Mission-critical facilities requiring megawatt-class backup

A representative example: A 50 Hz package using the CCEC KTA38-G5 engine delivers 720 kW/900 kVA prime and 880 kW/1000 kVA standby power when coupled to a Stamford HCI634J alternator. That’s enough to power a mid-size data center or keep a hospital’s critical systems running during extended outages.

Figure 1: Cummins KTA50-G3 diesel engine technical specifications. This V-16 cylinder, 50.3L displacement engine features turbocharging and aftercooling technology, delivering prime power from 1,097 kW (50Hz) to 1,220 kW (60Hz), with standby ratings up to 1,380 kW. Fuel consumption at full load: approximately 261 liters per hour, making it ideal for megawatt-class mission-critical facilities.

Fuel Efficiency and Operating Economics

Specific fuel consumption (SFC) is where Cummins engineering shows its value. The KTA38-G5 configuration achieves approximately 0.202 kg/kWh at 100% prime load (1500 rpm). To put that in perspective:

- Running 720 kW continuously for 8 hours consumes roughly 1,164 liters of diesel

- At $1.00/liter, that’s $145.50 per hour of operation

- Over a 24-hour outage, fuel costs would be approximately $3,492

These numbers matter when you’re comparing total cost of ownership. Cummins’ jacket-water aftercooling and step timing control aren’t just technical features—they directly improve cold-start reliability and reduce fuel consumption at light loads, where many gensets spend most of their runtime during testing and partial-load operation.

Alternator Integration and Power Quality

Cummins pairs their engines with precision-matched alternators from established brands:

- Stamford (Cummins Generator Technologies): HCI, UCI, and PI series

- Marathon (Regal Rexnord): Three-phase industrial alternators

- Voltage regulation: Typically ±1% with electronic governors

- Harmonic distortion: <3% THD for clean power suitable for sensitive electronics

This integration matters for data centers and healthcare facilities where power quality directly affects equipment lifespan and uptime. A poorly matched alternator can introduce voltage fluctuations that damage servers, medical equipment, and process control systems.

Why China Manufacturing Matters for Cummins Gensets

When procurement managers see “Made in China” on power generation equipment, legitimate questions arise about quality, support, and long-term reliability. But China-manufactured Cummins gensets occupy a unique position in the market—and understanding why reveals significant advantages.

Global Standards, Local Production

Chongqing Cummins Engine Company (CCEC) isn’t an independent licensee making “Cummins-style” engines. It’s a joint venture where Cummins maintains direct engineering oversight and quality control. CCEC-built engines meet the same SAE, ISO, and EPA (where applicable) standards as engines produced in Columbus, Indiana. The difference? Manufacturing costs in China run 20-30% lower due to labor rates, local supply chains, and production scale.

Chinese genset integrators who package these engines must meet international certifications:

- ISO 8528: International standard for reciprocating internal combustion engine-driven alternating current generating sets

- GB/T 2820: Chinese national standard (harmonized with ISO 8528)

- CE marking: For units destined for European markets

- UL 2200: For installations requiring U.S. safety certification

A well-specified China Cummins genset data sheet will explicitly list ISO 8528 and GB/T 2820 compliance, along with type-test reports and load bank verification results. If these aren’t present, you’re probably not dealing with a tier-one integrator.

Cost-Effectiveness Without Compromise

Let’s talk numbers. A 1000 kVA (800 kW) Cummins genset manufactured and integrated in China typically costs $45,000-$65,000 FOB, depending on specification and alternator brand. A comparable unit assembled in Europe or North America might run $75,000-$95,000. That’s a 30-40% price advantage—enough to fund an entire preventive maintenance program for the first five years of operation.

But here’s what you’re not sacrificing for that savings:

- Genuine Cummins engine and drivetrain components

- Factory load testing and commissioning

- Global parts availability through Cummins’ distributor network

- Technical documentation and service manuals

- Warranty support (typically 1-2 years or 1,000-2,000 hours)

Companies like Tesla Power have built their reputation on delivering China-manufactured Cummins gensets that meet international quality benchmarks while offering compelling ROI for industrial buyers. The key is working with integrators who maintain proper certifications, use genuine components, and stand behind their work.

Figure 2: Comprehensive comparison of Cummins generator engine platforms manufactured at CCEC. The KTA19 (inline-6, 18.9L, 336-522 kW) serves hospitals and commercial buildings; KTA38 (V-12, 38L, 690-821 kW) powers manufacturing plants and data centers; KTA50 (V-16, 50L, 1,000-1,500 kW) handles mission-critical facilities requiring megawatt-class backup power.

Industrial Applications Across Key Sectors

The true test of any emergency power supply system isn’t in the specifications—it’s in how it performs when the grid fails. China Cummins generator sets have proven themselves across industries where downtime literally costs lives or millions in lost revenue.

Data Centers: Where 99.999% Uptime Is the Baseline

Data centers represent one of the most demanding applications for backup power. When a facility promises “five nines” (99.999%) uptime, that allows for just 5.26 minutes of downtime per year. Backup power solutions must kick in within 10-15 seconds of a grid failure and sustain full load for hours or days.

Cummins addresses this with several approaches:

- N+1 redundancy configurations: Multiple gensets paralleled so one unit can fail without affecting uptime

- DCC (Data Center Continuous) ratings: Special duty cycles designed for extended runtime

- Load bank-tested performance: Pre-delivery verification at 100% load for 2-4 hours

A real-world example: Samsung’s data center facilities use Cummins gensets rated above 600 kVA in parallel configurations. When utility power drops, automatic transfer switches detect the outage, generators start within 10 seconds, and IT loads transfer seamlessly. The facility can run indefinitely as long as diesel fuel is available—and in practice, data centers typically maintain 48-72 hours of on-site fuel storage.

Figure 3: Modern data center backup power infrastructure featuring Cummins generators in N+1 redundancy configuration. This setup ensures 99.999% uptime by maintaining one additional backup unit beyond minimum requirements. Cummins systems range from 20kW to 3.5MW, with automatic transfer switches responding within 10 seconds of grid failure—critical for facilities where 5.26 minutes of annual downtime is the maximum allowable threshold.

Healthcare: Powering Life-Critical Systems

Hospitals face a unique challenge: partial power failures are almost as dangerous as total blackouts. Operating rooms, ICUs, ventilators, and monitoring systems require continuous duty generator backup that transitions without interrupting sensitive medical equipment.

Cummins diesel engines excel here because of:

- Fast pickup of block loads: Stepping from 0% to 75% load in under 10 seconds without voltage sag

- Low harmonic distortion: Protecting sensitive monitoring and imaging equipment

- Quiet enclosures: Sound-attenuated models that meet hospital noise ordinances (typically 65-75 dBA at 7 meters)

Many healthcare facilities opt for the KTA38 or KTA50 series for whole-facility backup (800-1,500 kW), with smaller units (100-250 kW) dedicated to code-required life safety circuits.

Manufacturing and Industrial Facilities

For manufacturers, unplanned shutdowns mean lost production, damaged work-in-process, and equipment damage. Process industries (chemicals, food production, pharmaceuticals) face additional risks: batch spoilage and safety hazards from interrupted environmental controls.

Industrial power backup requirements often include:

- Peak shaving and load management: Running gensets during utility demand peaks to reduce electricity costs

- Prime power operation: Using gensets as the primary power source in remote locations

- Black start capability: Restarting entire facilities without external power

The KTA19 and KTA38 series handle most manufacturing applications, with larger facilities deploying multiple units in parallel for load sharing and redundancy. Properly maintained Cummins gensets in industrial service commonly exceed 20,000 operating hours before major overhaul—that’s 2-3 years of continuous operation.

Construction and Remote Sites

Construction sites and remote industrial operations (mining, oil/gas) need gensets that tolerate harsh conditions: dust, temperature extremes, vibration, and minimal maintenance infrastructure.

China-manufactured Cummins units address these demands with:

- Heavy-duty air filtration: Multi-stage systems for dusty environments

- Tropical radiators: Oversized cooling for high ambient temperatures (up to 50°C)

- Containerized solutions: Weather-protected ISO container packages with integrated fuel tanks

Cummins’ Centum Force containerized gensets (1,500-2,200 kW) exemplify this approach—self-contained power plants that fit on standard trailers, eliminating expensive oversized freight and reducing commissioning time from weeks to days.

Key Factors Affecting Generator Performance and Reliability

Not all gensets with the same nameplate rating perform equally. Several factors determine whether your diesel generator reliability meets expectations or becomes a maintenance headache.

Ambient Conditions and Derating

Manufacturers rate gensets at standard conditions: 25°C, sea level, 30% relative humidity. Real-world installations rarely match these ideals. High altitude reduces air density, forcing engines to work harder. High temperatures stress cooling systems and reduce power output.

Derating factors you need to know:

- Altitude: -3.5% power per 300 meters above sea level

- Temperature: -1% power per 5°C above 25°C ambient

- Combined effects multiply: A genset at 1,500m elevation and 40°C ambient loses approximately 20% rated capacity

If your facility sits in a hot climate at elevation (think Denver in summer, or Middle East locations), specify “site-rated” power rather than assuming nameplate capacity. A properly specified 1000 kW genset might actually need a 1250 kW base rating to deliver 1000 kW at your specific site conditions.

Load Profile and Duty Cycle

Cummins defines several duty ratings:

- Standby (ESP): Maximum power available for emergency use, up to 200 hours/year, no sustained overload

- Prime (PRP): Unlimited hours/year at variable load, with 10% overload capacity for 1 hour per 12-hour period

- Continuous (COP): Unlimited hours at constant load, no overload capacity

- Data Center Continuous (DCC): Enhanced prime rating optimized for 24/7 operation

Using a standby-rated unit for prime power application will drastically shorten engine life and void warranties. The price difference between ratings reflects engineering trade-offs—higher continuous ratings use more conservative engine tuning, larger cooling systems, and heavier-duty components.

Fuel Quality and Storage

Poor fuel quality causes more genset failures than any other single factor. Diesel fuel degrades over time, growing algae and bacteria when water enters the tank. The result: clogged filters, injector damage, and poor combustion.

Best practices for fuel management:

- Biocide treatment: Annual or semi-annual dosing to prevent biological growth

- Fuel polishing: Filtering stored fuel through dedicated systems to remove water and particulates

- Tank inspection: Annual visual inspection for corrosion, water, and contamination

- Fuel rotation: Use and replace stored fuel every 6-12 months

Companies like Tesla Power often include fuel management guidance as part of their turnkey installation packages, because they know that even the best genset will fail if you feed it contaminated fuel.

Maintenance Intervals and Service Quality

Cummins publishes detailed maintenance schedules based on operating hours or calendar time, whichever comes first. Critical intervals include:

- 50 hours / 1 month: Check engine oil level, coolant level, belts

- 250 hours / 6 months: Change engine oil and filters, inspect cooling system

- 500 hours / 12 months: Load bank test (verify performance under full load)

- 1,000 hours / 24 months: Major service including valve adjustment, injector inspection

The “calendar time” requirement catches many facilities off-guard. A genset that only runs for monthly tests still needs annual oil changes and full load testing, because seals dry out, fuel degrades, and coolant deteriorates even when the engine isn’t running.

Quality Standards, Certifications, and Testing Protocols

The difference between a reliable genset and an expensive paperweight often comes down to rigorous testing and adherence to international standards. Understanding these benchmarks helps you separate tier-one suppliers from those cutting corners.

ISO 8528: The Global Genset Standard

ISO 8528 is the international standard for reciprocating internal combustion engine-driven AC generating sets. It specifies:

- Part 1: Application, ratings, and performance requirements

- Part 5: Generating sets (defines power ratings: ESP, PRP, LTP, COP)

- Part 12: Emergency power supply to safety devices

When a China Cummins genset claims ISO 8528 compliance, the manufacturer should provide type-test reports demonstrating:

- Steady-state voltage regulation within ±2.5%

- Frequency regulation within specified limits (±5% for G2 class)

- Transient response (voltage recovery within 6 seconds after 100% load step)

- Harmonic distortion limits

- Temperature rise under sustained load

Request these reports during the quoting process. Their presence (or absence) tells you whether you’re dealing with a serious manufacturer or a broker re-selling equipment of unknown provenance.

GB/T 2820: China’s National Standard

GB/T 2820 is China’s national standard for gensets, substantially harmonized with ISO 8528. For domestic Chinese installations and many export applications, GB/T 2820 certification is mandatory. The standard covers similar technical requirements but adds specific provisions for altitude derating and environmental protection.

Quality Chinese manufacturers test to both ISO 8528 and GB/T 2820, providing documentation for each.

Factory Load Bank Testing

Paper certifications mean little if the genset hasn’t been proven under real load. Reputable integrators perform factory acceptance testing (FAT) before shipment:

- 25% load: 1 hour (verify stable operation, no unusual noise/vibration)

- 50% load: 1 hour (check cooling system performance)

- 75% load: 1 hour (evaluate governor response)

- 100% load: 2-4 hours (confirm sustained full-power capability)

- 110% load: 30 minutes (verify overload capacity for prime-rated units)

This testing should be documented with data logging of voltage, frequency, coolant temperature, oil pressure, and exhaust temperature across the load profile. Some buyers choose to witness FAT in-person or via video link—a practice that’s become standard for large data center deployments.

Cummins PowerCommand Control Systems

Modern Cummins gensets use PowerCommand digital control systems that provide:

- Real-time monitoring of 50+ engine and alternator parameters

- Automatic start/stop sequencing

- Load sharing and synchronization for paralleled units

- Remote monitoring via Ethernet, Modbus, or cellular connectivity

- Event logging and alarm history

PowerCommand controllers meet UL and CE requirements and integrate with building management systems (BMS) via industry-standard protocols. For critical facilities, this level of monitoring transforms a genset from a black-box emergency device into a managed asset you can proactively maintain.

Figure 4: PowerCommand Cloud™ remote monitoring system introduced for 2025 deployments. This cloud-based platform enables real-time monitoring of 50+ engine and alternator parameters, predictive analytics for maintenance scheduling, fleet management across multiple sites, and AI-integrated diagnostics. Operators can remotely start/stop generators, reset faults, and receive instant notifications via email, SMS, or mobile app—transforming gensets into proactively managed /assets.

How to Select the Right Cummins Generator Set for Your Needs

Procurement decisions made at the specification stage determine whether your genset delivers reliable service or becomes a source of frustration. Here’s a systematic approach to selecting the right unit.

Step 1: Calculate Your Actual Power Requirements

Don’t just add up nameplate ratings. Calculate starting inrush current for motors and transformers, which can be 3-7 times running current. A proper load analysis includes:

- Total connected load: Sum of all equipment kW ratings

- Demand factor: Realistic percentage of load operating simultaneously (typically 70-85%)

- Future growth: Add 20-25% capacity for expansion

- Starting surge: Account for largest motor starting current

For a data center drawing 600 kW steady-state with occasional 750 kW peaks, you’d specify an 800-900 kW prime-rated genset—not a 600 kW unit that can’t handle the surge without voltage sag.

Cummins offers sizing tools (like Power Suite software) that automate these calculations, or work with a distributor who understands your application.

Step 2: Define Your Duty Cycle and Runtime Requirements

Be honest about how you’ll use the genset:

- Standby/emergency only: 200 hours/year maximum, short run times (1-4 hours)

- Prime power: Unlimited hours, variable load, routine operation

- Continuous: 24/7 operation at near-constant load

- Peak shaving: Daily operation during utility demand peaks

Specifying standby-rated equipment for prime power duty will void warranties and lead to premature failure. The cost delta between ratings (typically 10-15%) is miniscule compared to the cost of an unexpected engine rebuild at 3,000 hours.

Step 3: Consider Site-Specific Factors

Your physical location affects genset performance:

- Ambient temperature: High-temp regions need larger radiators or evaporative cooling

- Altitude: Sites above 300m require derating or turbocharged models

- Noise restrictions: Urban locations may mandate super-silent enclosures (60 dBA @ 7m)

- Seismic zones: Earthquake-prone areas require reinforced mounting and flexible fuel connections

- Coastal/corrosive environments: Saltwater exposure demands marine-grade coatings

A genset optimized for a Minnesota warehouse won’t perform the same in a Dubai construction yard without specification changes.

Step 4: Evaluate Total Cost of Ownership (TCO)

Purchase price is just the starting point. Calculate 10-year TCO including:

- Initial capital: Equipment + shipping + installation

- Fuel consumption: Estimated annual runtime × SFC × fuel price

- Maintenance: Scheduled service labor + parts (typically $8,000-$15,000/year for 1 MW unit)

- Downtime risk: Cost of outage if genset fails during grid failure

- Efficiency improvements: Better SFC pays back through reduced fuel costs

A 1000 kW genset with 0.210 kg/kWh SFC costs about $15,000 more in fuel over 10,000 operating hours than a comparable unit at 0.195 kg/kWh SFC (assuming $1.00/L diesel). If the more efficient model costs $8,000 extra upfront, it pays for itself after 5,000 hours—plus you’re reducing carbon emissions.

Step 5: Verify Supplier Credentials and Support

Not all “Cummins generator” suppliers are equal. Validate:

- Authorized distributor status: Check Cummins’ official distributor list

- ISO 9001 certification: Quality management system for manufacturing processes

- Reference installations: Ask for 3-5 comparable projects you can verify

- After-sales support: Local service capability, parts inventory, emergency response time

- Warranty terms: Standard 1-2 years, but what’s covered? Labor? Travel? Consequential damages?

Companies like Tesla Power differentiate themselves through turnkey project management—handling engineering, logistics, installation, commissioning, and training as an integrated package rather than just dropping equipment at your gate.

Maintenance Best Practices and Lifecycle Management

The most sophisticated genset becomes unreliable without proper maintenance. Here’s what separates facilities with 99.9%+ availability from those experiencing preventable failures.

Establish a Documented Maintenance Schedule

Cummins publishes detailed maintenance requirements in operation and maintenance (O&M) manuals. Key tasks by interval:

Weekly (or before use)

- Visual inspection for leaks, damage, loose connections

- Check engine oil and coolant levels

- Verify battery voltage and charger operation

- Inspect fuel level and tank condition

Monthly (or 50 hours)

- Run genset under load for minimum 30 minutes (preferably 75-100% load)

- Exercise automatic transfer switch

- Check air filter restriction indicator

- Inspect belts, hoses, and connections

Semi-annually (or 250 hours)

- Change engine oil and oil filter

- Replace fuel filters

- Check coolant concentration and condition

- Clean/replace air filter

- Inspect exhaust system for leaks

- Verify governor and voltage regulation

Annually (or 500 hours)

- Perform load bank test at 100% rated load for 2 hours minimum

- Inspect and service cooling system

- Check/tighten electrical connections

- Inspect starter motor and charging system

- Test automatic transfer switch under load

- Analyze lubricating oil (send sample to lab)

- Drain and clean fuel tank (check for contamination)

Every 2 years (or 1,000 hours)

- Major service: valve adjustment, injector testing

- Replace coolant and flush system

- Inspect turbocharger

- Load bank test with full documentation

Critical point: Calendar intervals apply even if runtime is low. Oil oxidizes, seals dry out, and fuel degrades whether the engine runs or sits idle.

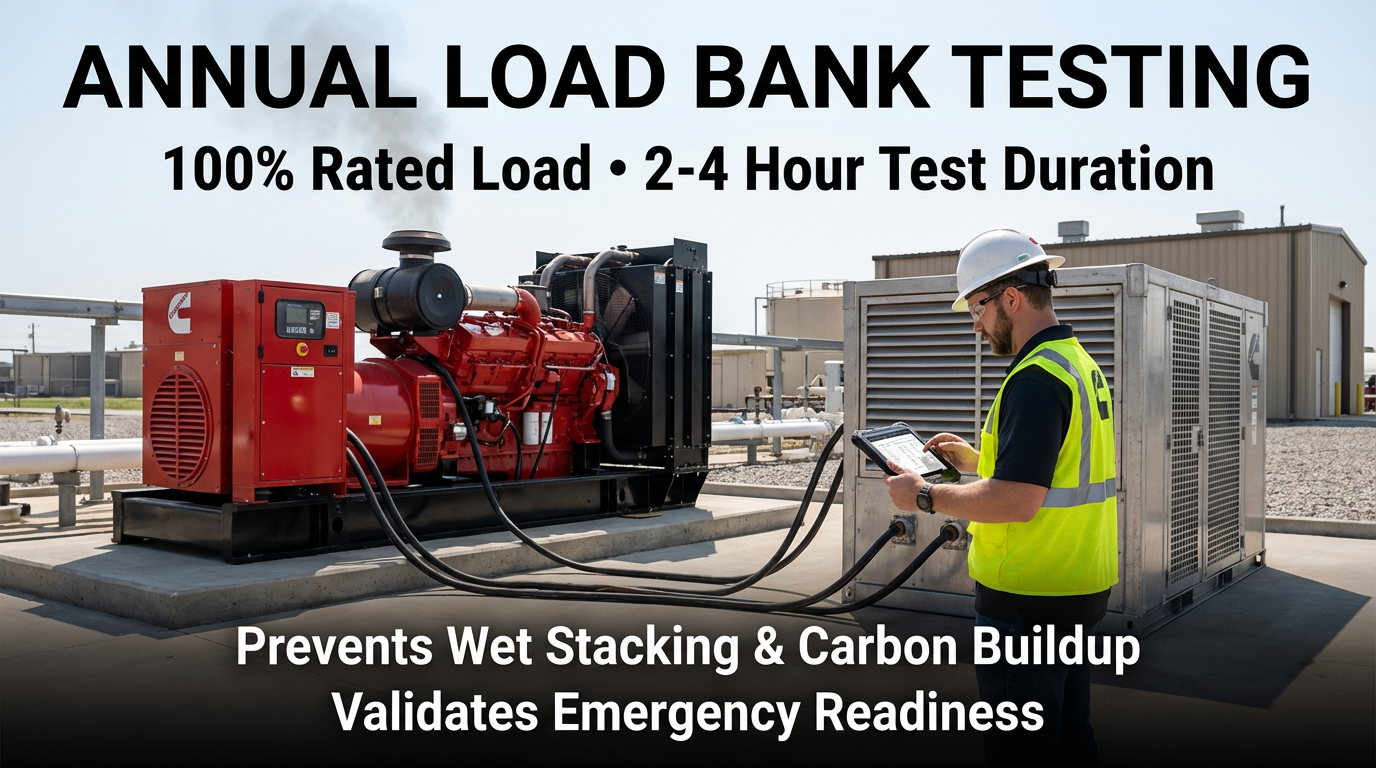

The Load Bank Test: Why It Matters

Running a genset at no-load or light load during monthly tests doesn’t prove it can handle a real outage. Light-load operation causes:

- Wet stacking: Unburned fuel accumulating in the exhaust system

- Carbon buildup: Coating valves, pistons, and injectors

- Incomplete combustion: Reducing fuel efficiency and increasing emissions

- Glazed cylinder walls: Reducing compression and power output

A proper load bank test applies 75-100% rated load for 2-4 hours, bringing the engine to full operating temperature and purging accumulated deposits. This “exercise” keeps the genset healthy and validates its readiness for an actual emergency.

Many facilities contract annual load bank testing to specialist service providers who bring portable resistive load banks on trucks. Cost: $2,000-$5,000 per test, depending on genset size—cheap insurance compared to discovering your 1 MW genset can only deliver 600 kW when the grid fails.

Figure 5: Professional load bank testing procedure for Cummins generator validation. Annual testing at 100% rated load for 2-4 hours prevents wet stacking (unburned fuel accumulation), carbon buildup, and glazed cylinder walls caused by light-load operation. This mandatory maintenance step validates emergency readiness and is required for warranty compliance. Testing costs $2,000-$5,000 but prevents the catastrophic scenario of discovering reduced capacity during an actual grid failure.

Predictive Maintenance Through Oil Analysis

Modern oil analysis programs detect problems before they cause failures. A lab analyzes your oil sample for:

- Wear metals (iron, copper, lead): Indicate bearing, piston, or valve wear

- Contaminants (silicon, sodium): Show air filter or coolant leaks

- Fuel dilution: Suggests injector or seal problems

- Oxidation and nitration: Indicate oil degradation

Trend analysis over multiple samples reveals gradual changes that predict impending failures. Catching a bearing issue at 500 ppm iron wear might mean a $5,000 repair; waiting until catastrophic failure could mean a $50,000 engine rebuild.

Cummins Planned Maintenance Programs

Cummins offers structured maintenance programs through authorized distributors:

- QuickServe Online: Parts lookup, service manuals, technical bulletins

- Planned Maintenance Agreements: Scheduled service with guaranteed response times

- Extended Warranties: Coverage beyond standard 2 years/2,000 hours

- QuickFIT Oil Change Systems: Simplified fluid service to reduce maintenance time

For mission-critical facilities, a planned maintenance agreement removes the risk of deferred maintenance and ensures trained technicians perform services using genuine parts. The premium over DIY maintenance (typically 15-20%) is justified by reduced downtime risk and warranty protection.

Conclusion

China Cummins generator sets occupy a unique position in the global power generation market, combining world-class engineering with cost-effective manufacturing. For facility managers and procurement teams evaluating backup power solutions, the value proposition is compelling: genuine Cummins engines meeting international standards (ISO 8528, GB/T 2820), integrated with precision-matched alternators and control systems, delivered at roughly 30-40% below Western-assembled equivalent units.

The key to success lies in working with reputable integrators who maintain proper certifications, perform rigorous factory testing, and provide comprehensive after-sales support. Companies like Tesla Power demonstrate that China-manufactured Cummins gensets can deliver the diesel generator reliability that mission-critical facilities demand—whether you’re powering a data center through multi-day grid outages, keeping hospital operating rooms lit during storms, or maintaining production in a pharmaceutical plant.

As Asia-Pacific continues to lead global demand for power generation equipment, with data centers and heavy industry driving growth in the >750 kVA segment, China Cummins generator sets are positioned to serve this expanding market. The combination of CCEC’s manufacturing scale, Cummins’ global engineering resources, and China’s logistics infrastructure creates a supply chain optimized for both cost and quality.

For your next power system procurement, look beyond simplistic “Made in China” concerns. Evaluate suppliers on their certifications, test documentation, reference installations, and support capabilities. Specify site-rated power accounting for altitude and temperature. Commit to proper maintenance including annual load bank testing. Make these choices correctly, and your China Cummins generator set will deliver decades of reliable service—powering the operations your business can’t afford to lose.

Frequently Asked Questions

What is the typical lead time for a China Cummins generator set?

Lead times depend on genset size and customization level. Standard configurations (500-1000 kW) with common alternators typically ship within 4-6 weeks from order confirmation. Larger units (>1500 kW), custom enclosures, or special voltage/frequency combinations may require 8-12 weeks. Containerized solutions like Centum Force units often have longer lead times (10-14 weeks) due to integrated systems integration and testing. Factor in shipping time (2-4 weeks ocean freight to most destinations) and allow 30-45 days for customs clearance and inland transport. Total project timeline from PO to commissioning: 3-4 months for standard units, 4-6 months for complex installations.

How does fuel consumption compare between different Cummins engine models?

Specific fuel consumption (SFC) varies by engine model, load level, and configuration. Representative values at 100% prime load: KTA19 series: 0.210-0.220 kg/kWh; KTA38 series: 0.195-0.205 kg/kWh; KTA50 series: 0.190-0.200 kg/kWh. Larger displacement engines generally achieve better SFC due to improved thermodynamic efficiency. However, fuel consumption increases dramatically at light loads—a genset running at 25% load may consume 60-70% of the fuel it uses at 75% load, making proper sizing critical. Cummins’ jacket-water aftercooling and step timing control features help reduce light-load fuel consumption by 5-10% compared to older engine designs.

Are China-manufactured Cummins engines covered by Cummins’ global warranty?

Yes, genuine CCEC-built Cummins engines carry Cummins’ standard warranty when the complete genset is purchased through authorized channels. Typical coverage: 12-24 months or 1,000-2,000 operating hours, whichever comes first. Warranty applies to engine components (block, heads, crankshaft, fuel system) but may have separate terms for alternator and control systems depending on the manufacturer. Critical requirement: maintain documented service records following Cummins’ maintenance schedules and use genuine Cummins parts for repairs. Warranty claims require validation by authorized Cummins distributors. Extended warranty programs (up to 5 years) are available through Cummins’ planned maintenance agreements.

What maintenance qualifications do technicians need to service Cummins gensets?

Routine maintenance (oil changes, filter replacements, visual inspections) can be performed by facility maintenance staff with basic mechanical training and Cummins’ O&M manuals. However, warranty compliance typically requires that major services (valve adjustments, injector testing, governor calibration, load bank testing) be performed by Cummins-certified technicians. Cummins offers training programs through regional service centers: Level 1 (basic troubleshooting), Level 2 (preventive maintenance), Level 3 (engine overhaul). Many facilities balance cost and warranty protection by having in-house staff handle weekly/monthly tasks while contracting annual major services to authorized distributors. For mission-critical installations, consider Cummins’ planned maintenance agreements that bundle certified technician services with parts and emergency support.

How long can a Cummins generator run continuously during a power outage?

Runtime is limited only by fuel supply and maintenance requirements, not the genset itself. Properly specified prime-rated or continuous-duty Cummins gensets can run indefinitely with appropriate fuel replenishment and periodic service. Practical considerations: Most facilities design for 48-72 hours of on-site fuel storage (meeting fire codes and tank size constraints). Data centers and hospitals often maintain 7-day fuel supplies and have contracts with fuel delivery services for extended outages. During operation, monitor engine parameters (coolant temperature, oil pressure) and perform basic checks every 8-12 hours. For runs exceeding 24 hours, schedule brief shutdowns (30-60 minutes) every 48-72 hours to inspect for leaks, check fluid levels, and verify system health. Record shows Cummins gensets operating continuously for weeks during natural disasters and grid failures, with proper monitoring and maintenance.

References

- Cummins Generator Sets – Official Product Line

- ISO 8528 Standard for Generating Sets

- GB/T 2820 Chinese National Standard

- Chongqing Cummins Engine Company (CCEC) Official Site

- Global Market Insights – Diesel Generator Market Report 2025

- Cummins PowerCommand Digital Control Systems

- Cummins Planned Maintenance Programs