Yet most facility managers don’t fully understand the elegant mechanics powering these critical machines. How exactly does fuel become electricity? What components orchestrate this transformation? And why do diesel generators remain the gold standard for reliable backup power in environments where downtime is simply unacceptable?

This isn’t academic curiosity—understanding your diesel generator can mean the difference between graceful recovery and catastrophic failure.

What is a Diesel Generator Set (Genset)?

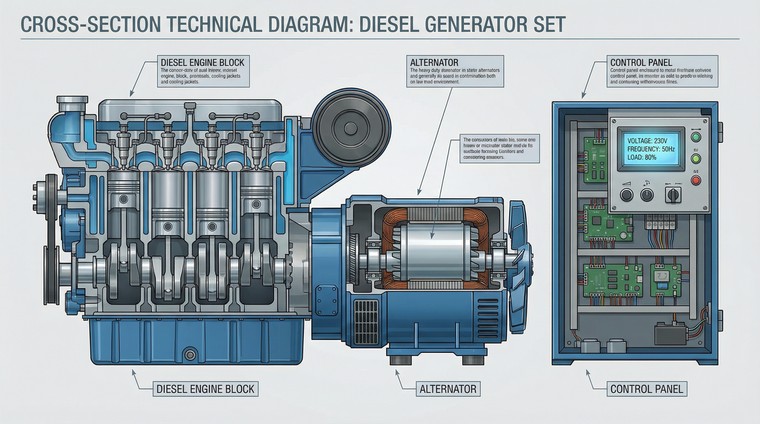

A diesel generator set is a self-contained power generation unit comprising three essential components working in perfect synchronization:

- The Diesel Engine: Burns fuel to create mechanical energy through controlled combustion.

- The Alternator: Converts mechanical rotation into electrical current.

- The Control System: Monitors conditions and manages power delivery to connected equipment.

Let me be precise about terminology. The term “genset” is shorthand for the complete assembly—it’s not just the engine, and it’s not just the alternator. Industry professionals distinguish between a genset (complete system ready to deploy) and individual components. This matters because sizing your backup power correctly depends on understanding the entire genset as an integrated system, not separate parts.

Image: Cross-section diagram showing diesel engine, alternator, and control panel components

The Diesel Engine: Converting Fuel into Mechanical Energy

At the core sits a diesel engine—one of engineering’s most efficient machines. Here’s how it transforms diesel fuel into the spinning force that drives electricity generation.

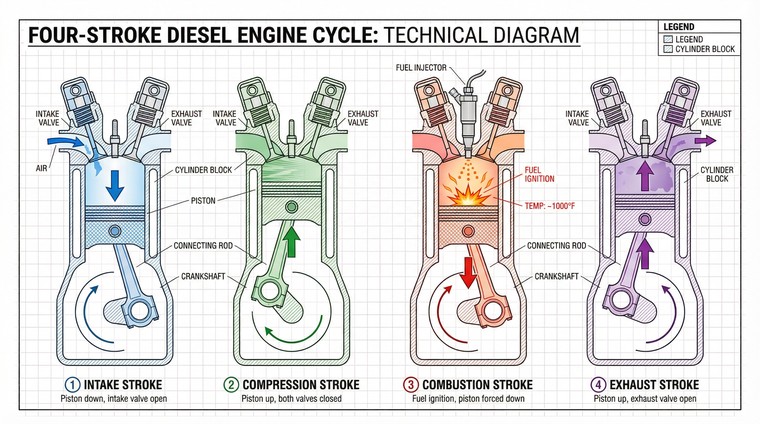

The process follows four strokes:

Intake Stroke: The piston moves downward, drawing in a fresh charge of compressed air. Unlike gasoline engines, diesel engines don’t spray fuel during this phase.

Compression Stroke: The piston rises sharply, compressing the air to roughly 15–20 times its original volume. This compression heats the air to approximately 1,000°F—hot enough to ignite fuel on contact.

Combustion Stroke: At maximum compression, fuel injectors spray diesel fuel into the chamber. The superheated air ignites it instantly (no spark plug needed). The resulting explosion drives the piston downward with tremendous force, and this is where power is generated.

Exhaust Stroke: The piston rises again, pushing burnt gases out through the exhaust valve, preparing the cylinder for the next cycle.

This cycle repeats hundreds of times per minute. A diesel engine in a diesel generator might run at 1,800 or 3,600 RPM depending on its design—each revolution cycles through all four strokes, each stroke contributing to rotational force.

Problem-Solution Insight: Many operators overlook that diesel engines in stationary applications run more efficiently than their automotive cousins because they maintain steady RPM under constant load. However, this also means they’re sensitive to quality control. Poor-quality diesel fuel causes injector clogging and reduced performance. Solution: Source diesel from reputable suppliers and conduct fuel testing on stored reserves to catch contamination before it damages injectors.

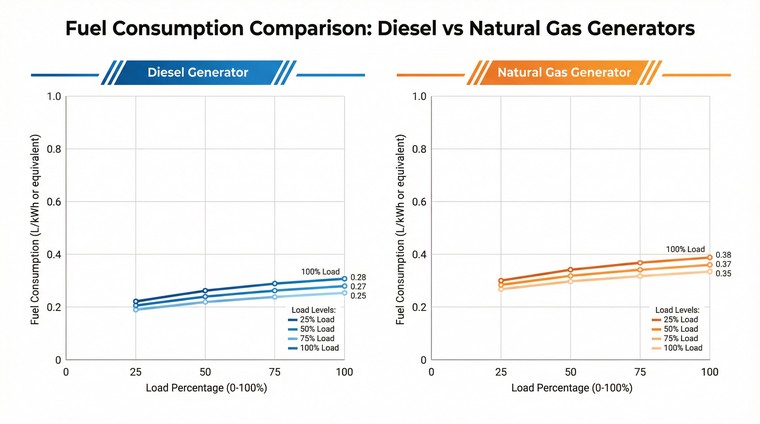

A critical advantage of the diesel engine is its fuel efficiency. Compared to natural gas engines of equivalent power, diesel engines extract more power generation per unit of fuel—a measurable advantage when calculating emergency runtimes.

Image: Technical diagram of 4-stroke engine showing intake, compression, combustion, and exhaust strokes

The Generator Alternator: Converting Rotation into Electricity

Once the diesel engine is spinning, the generator alternator steps in. This device transforms mechanical rotation into electrical current through electromagnetic induction—one of physics’ most elegant principles.

Inside the generator alternator:

- A rotor (spinning magnetic field) rotates at the engine’s RPM.

- A stator (stationary coil of copper wire) surrounds it.

- As the rotor’s magnetic field passes through the stator’s windings, it induces electrical current.

The faster the rotation and the stronger the magnetic field, the higher the voltage and current output. This is why engine RPM directly affects electrical output—and why a diesel generator designed for 1,800 RPM produces different power characteristics than one running at 3,600 RPM.

A generator alternator is rated in kVA (kilovolt-amperes, apparent power) or kW (kilowatts, real power). The relationship between them involves the “power factor,” typically 0.8 for industrial generator sets. So a 100 kVA unit delivers 80 kW of usable power. Most facility managers size equipment based on kW requirements of actual loads.

Delivering the Energy: Control Systems and Power Transfer

Generating electricity is only half the battle; delivering it safely to your facility requires sophisticated control systems.

The Brain: The Control Panel

Modern industrial generator sets are equipped with digital control panels that act as the brain of the operation. These interfaces monitor oil pressure, coolant temperature, battery status, and engine speed. In advanced models, such as those from Tesla Power, the control panel offers remote monitoring capabilities, allowing facility managers to check genset status from a smartphone. This transparency means problems can be detected before they become emergencies.

The Gateway: Automatic Transfer Switch (ATS)

The ATS is the bridge between the utility grid and your generator. It constantly monitors the voltage coming from the utility grid. When it detects a power outage or a drop in power quality (brownout), it signals the diesel engine to start. Once the generator alternator synchronizes and reaches the correct voltage and frequency, the ATS physically switches the facility’s load from the grid to the generator. When grid power is restored and stabilizes, the ATS transfers the load back and commands the generator to cool down and shut off.

Operational Principles: Load Management and Efficiency

For a diesel generator to run efficiently and reliably, it must be loaded correctly. This is where load management becomes critical.

Understanding Load Steps

Diesel engines are remarkably resilient, but they prefer steady work. Load management involves organizing your facility’s electrical consumption so the generator isn’t overwhelmed by a massive spike (inrush current) at startup, nor underutilized.

Problem-Solution Insight: Running a large diesel generator with a very light load (under 30% capacity) causes incomplete combustion, leading to “wet stacking”—where unburned fuel accumulates in the exhaust system. This causes fire hazards, reduced performance, and permanent engine damage. Solution: Implement a load bank test annually to burn off these deposits, or right-size your diesel generator so it runs at 60-75% capacity during typical outages.

Power Ratings Explained

When browsing specifications, you will see three main ratings:

- Standby Power: The maximum power available for the duration of a power outage. Not intended for extended hours.

- Prime Power: Power available for an unlimited number of hours per year in a variable load setting.

- Continuous Rated Power: The power a generator can supply at a constant 100% load for an unlimited number of hours. This is vital for data centers or off-grid mining operations where the genset is the primary power source.

Why Choose Diesel? Advantages and Real-World Applications

Despite the rise of renewables and battery storage, the diesel generator remains the gold standard for reliable backup power across multiple sectors.

1. Response Time and Durability

A diesel engine can accept a full electrical load within 10 seconds of starting. This rapid response is non-negotiable for life-safety systems in hospitals. Furthermore, diesel engines are built with robust components to withstand higher compression, giving them a lifespan that often exceeds 20,000 operating hours—and with proper maintenance, sometimes double that.

2. Fuel Efficiency and Availability

Modern diesel engines have exceptional thermal efficiency. For every unit of fuel consumed, a diesel engine produces more energy, making power generation more cost-effective than natural gas alternatives. This fuel efficiency translates to longer runtimes during extended blackouts—a crucial factor when fuel delivery trucks cannot reach your facility due to weather.

Image: Side-by-side comparison chart showing fuel consumption rates (L/kWh) of diesel versus natural gas generators

Industry Applications

Healthcare: In hospitals, a power dip of even a second can reset life-support machines. Here, standby power is a life-or-death requirement. Redundant diesel generator arrays ensure that every operating room, every ICU bed, and every diagnostic machine stays online.

Data Centers: With the cost of downtime calculated in millions per minute, data centers rely on redundant diesel arrays to ensure 99.999% uptime (“five nines”). Multiple gensets work in parallel, distributing load across units for maximum reliability.

Construction and Mining: In remote locations lacking grid access, an industrial generator provides the continuous rated power needed to drive heavy machinery and camp infrastructure. These environments cannot tolerate downtime.

Problem-Solution Insight: Noise pollution is a major concern for generators located near offices or residential areas. Solution: Specify a sound-attenuated enclosure (often rated at 75 dBA or lower at 7 meters) and consider critical-grade mufflers to ensure your power generation doesn’t disrupt the neighborhood.

Maintenance: Protecting Your Investment

A diesel generator is an asset that requires respect. Neglect is the primary cause of start-up failures when you need it most.

The Fuel Quality Challenge

Problem-Solution Insight: Diesel fuel degrades over time. Sediments and water can form sludge that clogs filters. Solution: Use fuel stabilizers if the diesel sits for more than 6 months, and implement a “fuel polishing” schedule every 1-2 years to filter out contaminants from your storage tanks. This keeps your diesel generator ready for emergencies.

Routine Checklist

To ensure your genset is ready for the next crisis:

- Weekly: Run the generator (exercise) for 15-30 minutes under load to condition all components.

- Monthly: Check coolant levels and battery charge rates.

- Annually: Change oil, oil filters, and fuel filters. Inspect the generator alternator windings for dust or moisture. Verify that all electrical connections are tight and free from corrosion.

Manufacturers like Tesla Power emphasize that adherence to a strict maintenance schedule is the only way to validate warranties and ensure performance during an emergency.

Conclusion

The mechanics behind a diesel generator set are a testament to engineering reliability. By converting chemical potential into mechanical force and finally into electrical current, these machines underpin the safety and productivity of modern society. Whether you are safeguarding a small business or powering a massive industrial generator installation, understanding the roles of the diesel engine, the alternator, and load management empowers you to make smarter energy decisions.

Investing in a high-quality unit from a reputable provider like Tesla Power ensures that when the grid fails, your lights—and your business—stay on.

Frequently Asked Questions (FAQ)

1. How long can a diesel generator run continuously?

A well-maintained diesel generator can run as long as it has fuel. For continuous rated power applications, engines are designed to run for weeks at a time, stopping only for oil changes and scheduled maintenance. However, for standby units, most fuel tanks are sized for 24 to 48 hours of operation before needing a refill. Always verify the autonomy rating for your specific genset based on your facility’s load profile and fuel supply chain.

2. What is the difference between kW and kVA?

kW (kilowatts) is the actual power available to do work (real power), while kVA (kilovolt-amperes) is the apparent power, which includes reactive power used by magnetic circuits in motors. For most diesel generators, the power factor is 0.8, meaning 100 kVA equals 80 kW. Always size your genset based on the kW rating of your equipment to avoid overloading the engine and triggering shutdown protection systems.

3. Can a diesel generator run on biodiesel?

Yes, many modern industrial generator engines can run on biodiesel blends (like B5 or B20). However, biodiesel has different solvent properties and a shorter shelf life than standard diesel. Consult the manufacturer’s manual before switching fuels to ensure it won’t void the warranty or damage the fuel system components, injectors, or seals.

4. Why is wet stacking bad for a generator?

Wet stacking occurs when a diesel engine runs below its optimal operating temperature (usually due to light loads below 30% capacity). Unburned fuel and carbon accumulate in the exhaust system, leading to fire hazards, reduced performance, and permanent engine damage. Avoiding this requires proper load management and periodic load bank testing to keep the system healthy and efficient.

5. How often should I replace the battery on my generator?

Battery failure is the #1 reason for standby diesel generator failure. Even if the battery shows a charge, it should be replaced every 2 to 3 years. Industrial starting batteries face high loads during cranking, and their capacity diminishes over time, making them unreliable for that critical moment when the standby power system needs to start. Regular battery load testing can extend life by identifying weak cells early and preventing unexpected failures.