If you’ve ever wondered how a backup power system springs to life during an outage, or what’s really happening inside that big metal box humming away at a construction site, you’re in the right place. Understanding how does a diesel generator work isn’t just for engineers—it’s valuable knowledge for anyone considering a backup power investment or working in industries where reliable electricity is non-negotiable.

At Tesla Power, we’ve spent years manufacturing and installing diesel generator sets across mining operations, hospitals, data centers, and remote facilities. Through that experience, we’ve learned that demystifying the technology helps our customers make better decisions. So let’s pull back the curtain and walk through exactly how these workhorses convert fuel into electricity.

The Simple Answer: From Combustion to Current

Here’s the core concept: a diesel generator combines a diesel engine with an electrical alternator to convert mechanical energy into electrical power. Think of it like a massive version of the alternator in your car—except instead of keeping your car battery charged, it’s powering your entire facility.

The diesel engine burns fuel to create rotational force (torque), which spins the alternator’s rotor. That spinning motion inside a magnetic field induces an electric current in the stator windings, producing the AC power that runs your equipment. Simple in concept, sophisticated in execution.

Key Components: What’s Inside a Diesel Generator Set

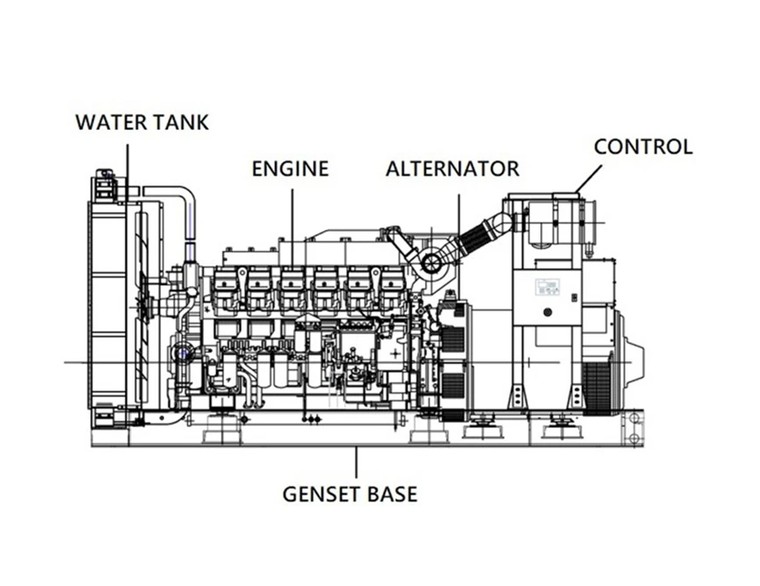

Before we dive into the process, let’s identify the major players. A complete genset (industry shorthand for generator set) includes:

Diesel EngineThe prime mover—typically a 4-stroke compression-ignition engine ranging from 10 kW single-cylinder units to 3,000+ kW multi-cylinder industrial powerhouses. Brands like Cummins, Perkins, and others engineer these specifically for generator duty cycles.

Alternator (Generator End)The electrical component that converts mechanical rotation into AC power. Consists of a rotor (spinning electromagnet) and stator (stationary wire windings). Output voltage and frequency depend on rotor speed and winding configuration.

Fuel SystemIncludes the fuel tank, fuel pump, injectors, and filters. Modern systems use electronic fuel injection for precise metering and efficiency.

Cooling SystemMost industrial generators use radiator-based liquid cooling, though smaller portable units may use air cooling. Keeps engine temperatures within safe operating range during extended runtime.

Exhaust SystemChannels combustion gases away safely, often with mufflers to reduce noise. Some applications require spark arrestors or emissions controls.

Lubrication SystemPressurized oil system keeps engine components properly lubricated. Oil coolers and filters maintain oil quality during continuous operation.

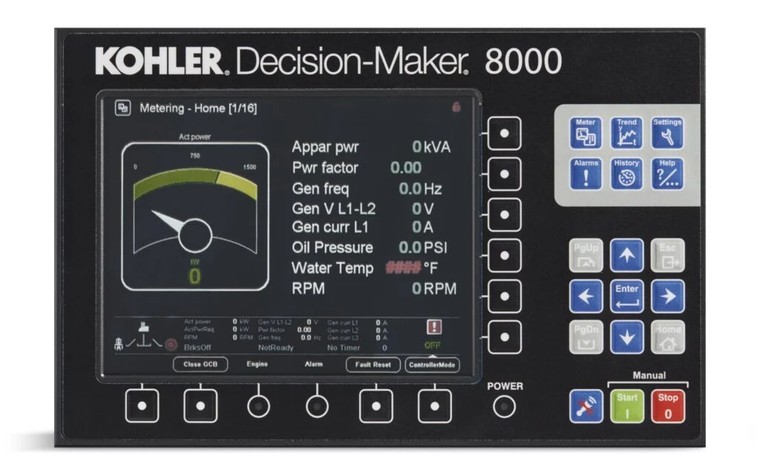

Control PanelThe brain of the system—monitors voltage, frequency, oil pressure, coolant temperature, and battery charge. Handles automatic starting, load transfer, and shutdown sequences.

Automatic Transfer Switch (ATS)Not part of the generator itself, but critical to backup power solutions—detects utility failure and switches your facility to generator power within seconds.

Battery and Charging SystemProvides cranking power for the starter motor. The generator’s alternator charges the batteries during operation, keeping them ready for the next start cycle.

How Does a Diesel Generator Work? The Step-by-Step Process

Now that you know the parts, let’s walk through what happens when you fire up a diesel generator set. I’ll break this into the four-stroke combustion cycle and the electrical generation process.

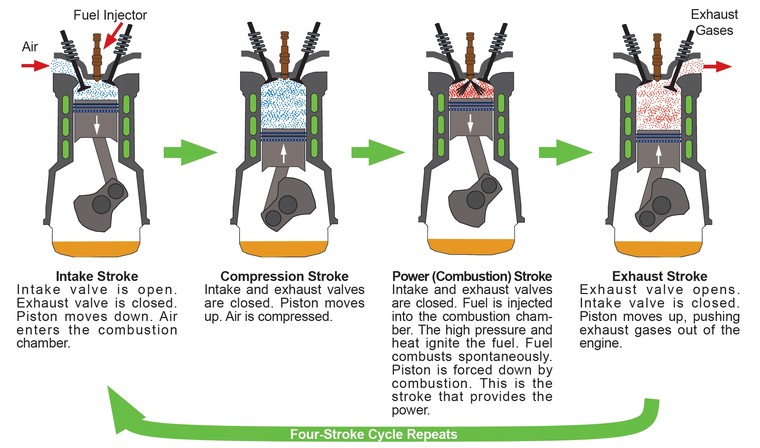

The Four-Stroke Diesel Combustion Cycle

Unlike gasoline engines that use spark plugs, diesel engines rely on compression ignition. Here’s how the cycle works:

1. Intake StrokeThe piston moves down, creating a vacuum that draws fresh air (and only air—no fuel yet) through the open intake valve into the cylinder. This air needs to be clean, which is why quality air filters matter for diesel generator efficiency.

2. Compression StrokeBoth valves close. The piston moves upward, compressing the air to about 1/15th of its original volume. This intense compression heats the air to roughly 500-700°C (900-1300°F)—hot enough to ignite diesel fuel without a spark.

3. Power Stroke (Combustion)Just before the piston reaches the top of the compression stroke, the fuel injector sprays a fine mist of diesel into the superheated compressed air. The fuel ignites instantly, creating a controlled explosion that drives the piston back down with tremendous force. This is where the mechanical energy comes from.

4. Exhaust StrokeThe exhaust valve opens, and the piston moves back up, pushing spent combustion gases out through the exhaust system. Then the cycle repeats—hundreds or thousands of times per minute, depending on engine speed.

In a typical generator application, the engine runs at a constant 1500 RPM (for 50 Hz output) or 1800 RPM (for 60 Hz output) to maintain stable electrical frequency.

From Mechanical Rotation to Electrical Current

While the diesel engine is cranking through those four-stroke cycles, it’s spinning the crankshaft. That crankshaft connects directly (or through a coupling) to the alternator shaft. Here’s where mechanical energy becomes electricity:

Step 1: Rotor SpinningThe alternator’s rotor—essentially an electromagnet—spins inside the stator at the same speed as the engine. The rotor receives a small DC current (excitation current) from the control panel, creating a strong magnetic field.

Step 2: Electromagnetic InductionAs the magnetic field spins past the stator windings (coils of copper wire arranged around the rotor), it induces an alternating current in those windings. This is Faraday’s Law in action—the same principle behind every electric generator since the 1830s.

Step 3: Voltage RegulationThe control system constantly monitors output voltage. If voltage drops (due to increased load), the automatic voltage regulator (AVR) increases excitation current to the rotor, strengthening the magnetic field and boosting output. This keeps your voltage stable whether you’re running one light bulb or a full factory load.

Step 4: Power OutputThe three-phase AC power (or single-phase, depending on configuration) exits through the generator terminals, passes through circuit breakers, and feeds your facility’s electrical system. The power output kW/kVA depends on engine size and alternator design—anywhere from 5 kW portable units to 3+ MW industrial installations.

Common Misconceptions About How Diesel Generators Work

Let’s clear up some confusion we hear frequently:

Myth 1: “Generators create electricity from nothing”Not quite. Generators don’t create energy—they convert it. The chemical energy in diesel fuel converts to heat energy (combustion), then mechanical energy (piston and crankshaft movement), and finally electrical energy (alternator output). It’s energy transformation, following the law of conservation of energy.

Myth 2: “Bigger generators always work better”Oversizing can actually harm performance. Running a generator at very light loads (below 30% capacity) causes wet stacking—unburned fuel deposits that foul injectors and reduce efficiency. At Tesla Power, we emphasize proper generator load capacity matching for this reason.

Myth 3: “Diesel generators provide DC power”Most commercial generators produce three-phase AC power (some smaller units produce single-phase AC). If you need DC power, you’ll add a rectifier/charger to convert it—the generator itself outputs alternating current.

Myth 4: “All generators produce the same quality power”Far from it. Cheap generators may have poor voltage regulation, high harmonic distortion, or frequency instability—all problems for sensitive electronics. Quality units maintain clean sine wave output with less than 5% total harmonic distortion (THD).

Why Diesel? The Advantages of Compression-Ignition Engines

You might wonder why diesel dominates the generator market, especially for prime power generators and industrial applications. Here’s why:

Fuel EfficiencyDiesel engines extract more energy per gallon than gasoline engines due to higher compression ratios and better thermal efficiency. We’re talking 20-30% better fuel economy, which adds up significantly over thousands of operating hours.

Durability and LongevityDiesel engines are built heavier and stronger to handle high compression forces. With proper generator maintenance, a diesel engine can run 15,000-30,000 hours before major overhaul—compared to 6,000-10,000 hours for comparable gasoline units.

Better Load ResponseDiesel engines handle sudden load changes more gracefully, with less frequency and voltage droop. That’s critical when a large motor starts up and temporarily demands 3-6 times its running current.

Lower Fire RiskDiesel fuel has a much higher flash point than gasoline (52°C vs. -43°C), making it safer to store and handle in large quantities. Important for applications requiring thousands of gallons of on-site fuel.

Widely Available FuelIn many parts of the world, diesel is more readily available than propane or natural gas—particularly important for remote locations like mining sites or offshore installations.

Practical Applications: Where Diesel Generators Shine

Understanding how diesel generators work helps you appreciate where they fit best:

Standby Emergency PowerHospitals, data centers, wastewater treatment plants, and other critical facilities use standby generators that automatically start during utility failures. These units typically run only 50-200 hours per year but must be absolutely reliable.

Prime Power for Off-Grid SitesConstruction sites, remote research stations, mining operations, and island communities use generators as their primary power source. These units run 24/7 or near continuously, making fuel efficiency and durability paramount.

Peak Shaving and Load ManagementSome facilities run generators during peak demand periods to avoid expensive demand charges from utilities. The generator supplements utility power rather than replacing it.

Mobile Power for Events and RentalMovie productions, outdoor concerts, emergency response—portable diesel generators mounted on trailers provide temporary power wherever it’s needed.

Factors That Affect How Well Your Diesel Generator Works

Knowing how a diesel generator works is one thing—keeping it working optimally is another. Several factors influence performance:

Ambient TemperatureHigh temperatures reduce air density, which means less oxygen per cylinder. Most manufacturers derate (reduce) output by 4% for every 10°C above 25°C. In hot climates, you might need a larger generator to deliver the same effective power.

AltitudeSimilarly, thinner air at elevation reduces power output. Expect a 3-4% power loss for every 300 meters above sea level. A generator rated for 500 kW at sea level might only deliver 425 kW at 1,800 meters elevation.

Fuel QualityContaminated or degraded diesel causes incomplete combustion, reduced power, and potential injector damage. Water in fuel (from condensation in storage tanks) is a common culprit. Regular fuel testing and polishing systems help maintain diesel engine reliability.

Load FactorRunning consistently at 70-80% of rated capacity is the “sweet spot” for most generators. Too light, and you risk wet stacking; too heavy, and you accelerate wear and risk overheating.

Maintenance Schedule AdherenceOil changes, filter replacements, cooling system service—these aren’t optional. Neglected maintenance is the #1 cause of generator failures. At Tesla Power, we provide detailed maintenance schedules with every unit, timed to operating hours rather than calendar dates.

What Makes a Quality Diesel Generator?

Not all generators are created equal. Here’s what separates professional-grade units from economy models:

Engine PedigreeReputable engine manufacturers (Cummins, Perkins, MTU, Volvo Penta) invest heavily in R&D and have proven track records. These engines are specifically designed for generator duty cycles, not repurposed from other applications.

Alternator QualityBrushless alternators with quality AVRs provide stable voltage and frequency regulation. Look for class H insulation (which handles higher temperatures) and IP23 or better ingress protection against dust and moisture.

Control System SophisticationModern controllers don’t just start and stop the generator—they provide real-time monitoring, predictive maintenance alerts, remote connectivity, and integration with building management systems. This intelligence prevents problems before they cause downtime.

Enclosure and WeatherproofingFor outdoor installations, weather-resistant or sound-attenuated enclosures protect components and reduce noise. Powder-coated steel, stainless steel fasteners, and proper ventilation extend equipment life.

Manufacturer Support NetworkWhen something goes wrong at 2 AM, can you get parts and service? A manufacturer’s support network—dealer locations, parts availability, technical support—matters as much as the hardware itself.

Understanding Generator Specifications

When you’re researching generators, you’ll encounter specifications that directly relate to how the generator works:

kW vs kVAkW (kilowatts) measures real power—the actual work being done. kVA (kilovolt-amperes) measures apparent power—the combination of real power and reactive power. For resistive loads (heaters, incandescent lights), they’re nearly equal. For inductive loads (motors, transformers), kVA is higher. Most generators are rated in kVA at 0.8 power factor, meaning a 100 kVA generator delivers 80 kW of usable power.

Prime vs Standby RatingsPrime power generators can run unlimited hours per year with varying loads, typically up to 80% of their maximum rating. Standby (emergency) ratings allow 100% output but only for limited hours per year (usually 200-500 hours). Using a standby-rated generator for prime power will shorten its life dramatically.

Engine Speed (RPM)1500 RPM (50 Hz) or 1800 RPM (60 Hz) generators are standard. Some smaller units run at 3000 or 3600 RPM, which means lighter weight but shorter lifespan due to increased mechanical stress.

Fuel ConsumptionTypically specified in liters per hour at various load levels. A 100 kW diesel generator running at 75% load typically consumes 20-25 liters per hour, though this varies by engine efficiency.

The Bottom Line: How Does a Diesel Generator Work?

Let’s bring it all together. A diesel generator works by combining the mechanical power of a compression-ignition diesel engine with the electromagnetic principles of an alternator. Diesel fuel combusts in the engine cylinders, driving pistons that rotate the crankshaft. That rotating shaft spins an electromagnet (rotor) inside stationary wire coils (stator), inducing alternating current through electromagnetic induction.

The entire system—from fuel delivery to voltage regulation—works in harmony to provide reliable electrical power whenever and wherever you need it. Whether it’s keeping hospital operating rooms lit during a utility failure, powering a remote mining operation, or providing backup for a data center’s critical servers, the fundamental process remains the same.

What varies is the sophistication of components, the quality of manufacturing, and the support network behind the equipment. That’s where working with an experienced manufacturer like Tesla Power makes a difference—we don’t just sell generators; we engineer complete power solutions backed by decades of field experience.

If you’re considering a diesel generator for your facility, understanding how these systems work gives you the foundation to ask the right questions, evaluate specifications intelligently, and make a confident investment in reliable backup power.

Frequently Asked Questions

Q1: Does a diesel generator produce AC or DC power?Most diesel generators produce AC (alternating current) power, either single-phase or three-phase, depending on their design. The alternator creates AC naturally through electromagnetic induction. If you need DC power, you would add a rectifier system to convert the AC output to DC.

Q2: Why do diesel generators need batteries if they generate electricity?The batteries provide starting power for the diesel engine’s starter motor—just like a car battery cranks your engine. Once the generator is running, its alternator charges the batteries while simultaneously supplying power to your loads. Without batteries, there’d be no way to initially start the engine.

Q3: Can a diesel generator run 24/7 continuously?Yes, prime power generators are designed for continuous operation and can run 24/7 indefinitely with proper maintenance. However, standby-rated generators are designed for limited annual hours (typically 200-500 hours per year) and shouldn’t be used for continuous prime power applications. Always check the manufacturer’s rating classification.

Q4: What’s the difference between kW and kVA ratings on generators?kW (kilowatts) represents real power—the actual usable energy doing work. kVA (kilovolt-amperes) represents apparent power, which includes both real power and reactive power. The relationship depends on power factor. Most generators are rated in kVA at 0.8 power factor, meaning a 100 kVA generator provides 80 kW of usable power.

Q5: How long does it take a diesel generator to start and provide power?Modern automatic transfer switches detect utility failure in milliseconds. The generator typically starts within 8-12 seconds and stabilizes voltage and frequency within another 3-5 seconds. Total time from outage to full backup power is usually 10-20 seconds—imperceptible for most equipment, though sensitive electronics may benefit from UPS systems to bridge that gap.

Looking to invest in a reliable diesel generator for your facility? Understanding how these systems work is just the first step. At Tesla Power, our engineering team can help you select, size, and configure the perfect backup power solution for your specific application. Contact us today for a consultation.