How Much Does Industrial Diesel Generator Manufacturing Cost and What Affects Pricing?

Ever noticed how two industrial generators can differ in price by $100,000? That gap seems to reveal something fundamental about how diesel generator manufacturing cost structures work—and it’s not just brand name markup.

I’ve reviewed thousands of generator specs and pricing sheets. Most procurement managers miss this: the final price tag reflects far more than raw production expenses. Understanding industrial diesel generator pricing means wrestling with five major variables that separate a $30,000 unit from a $200,000 powerhouse.

Let’s break down what’s really happening when you shop for an industrial diesel generator. The answer matters whether you’re protecting a data center, keeping a hospital online, or powering remote mining operations.

Understanding the Cost Structure Behind Industrial Generators

When manufacturers calculate diesel generator cost per kW, they’re working backward from your power requirements. But “cost per kilowatt” is only part of the story.

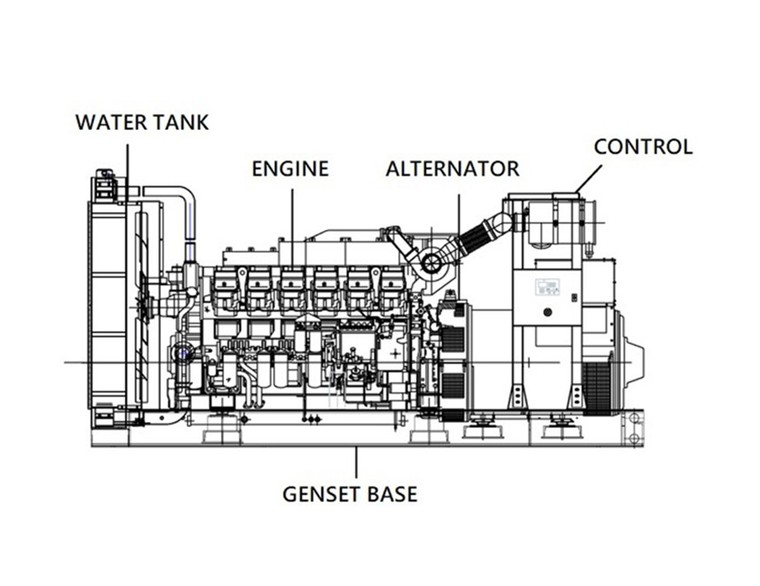

Here’s where it gets tricky: generator pricing isn’t linear. A 50 kW unit doesn’t necessarily cost half as much as a 100 kW model. Manufacturers build costs around economies of scale, component sourcing, and engineering standards. A small generator shares many expensive components with larger units—the cooling system, control panel, alternator—but these costs get distributed differently.

Most buyers think in terms of upfront purchase price. But industrial procurement teams need to think bigger. That’s where how much does industrial generator cost becomes an actual strategy question.

The Five Factors Driving Industrial Generator Prices

1. Power Output (kW/kVA Rating)

Your power output specification is the primary cost driver. It’s non-negotiable. Here’s the breakdown:

Small units (20-30 kW) run $14,000-$20,000. Mid-range systems (100 kW) land around $32,000-$40,000. Larger capacity (250 kW) units cost $50,000-$70,000. High-capacity systems (500 kW and above) start at $125,000 and climb to $300,000+.

Industry benchmarks suggest roughly $300-$450 per kW for new commercial-grade systems. So a 100 kW generator typically lands around $35,000-$45,000 depending on specification choices.

Here’s what matters: oversizing costs money today with zero operational benefit. Undersizing creates liability. Getting this calculation right is essential before shopping prices with manufacturers.

2. Generator Type: Standby vs. Prime Power Performance

This distinction reshapes your entire budget conversation.

Standby generators sit dormant until power fails. They’re built for occasional, short-term operation—typically under 500 hours annually. You’re paying for reliability during emergencies, not continuous duty. That’s why they’re less expensive.

Prime power generators operate daily, sometimes continuously. Engineers build them with heavier-duty construction, superior cooling systems, and reinforced components designed for sustained thermal stress and load cycling. They typically cost 30-50% more than equivalent standby models.

At larger capacities, the difference becomes stark. A 500 kW standby unit might run $180,000, while the prime power equivalent could approach $250,000-$300,000. That choice alone shapes 20–30% of your entire budget.

3. Manufacturer Brand and Engineering Quality

The brand difference isn’t just reputation—it’s engineering philosophy.

Established manufacturers like Cummins, Caterpillar (CAT), and Kohler command premium pricing because they’ve built long-term service networks, parts availability, and warranty credibility. These aren’t abstract benefits. When your generator fails during critical operation, fast parts replacement and technical support have real value.

Budget manufacturers exist, and sometimes they’re appropriate. But here’s what procurement managers discover: cheaper upfront doesn’t equal cheaper lifetime costs when warranty claims, maintenance complications, and parts scarcity enter the picture.

A Caterpillar 100 kW unit might run around $45,000; a generic import could be closer to $25,000. That cost gap reflects differences in alternator copper content, engine tolerance specs, control panel sophistication, and post-sales support. After two years of operation, the total cost of ownership often tells a different story.

Data shows that mid-tier manufacturers often deliver the best value—not the lowest price, but the best balance of quality, support, and cost.

4. Specifications and Certifications

Compliance requirements push prices upward, sometimes substantially.

ISO 8528 works differently—it’s a quality and performance standard that doesn’t necessarily add cost, but it certifies that the manufacturer tested the unit thoroughly. Premium buyers specifically seek ISO 8528 certification because it proves performance consistency.

CE marking requirements for European markets add compliance costs. Different regional emissions standards (EPA Tier 4 in the US, EU Stage V in Europe, CARB in California) mean that global manufacturers must engineer equipment that adapts to these varying standards or maintain separate production lines.

The engineering cost is real. It doesn’t disappear in the price.

5. Customization and OEM Manufacturing

Off-the-shelf generators have one pricing structure. Custom work has another entirely.

Custom diesel generator manufacturing involves non-standard configurations: unique fuel tank sizes, specialized control panel integration, container mounting, acoustic enclosures, or specific cooling requirements. Each customization adds engineering hours, tooling setup, and testing.

A container-mounted 500 kW system designed for marine operations differs substantially from a standard industrial unit. That Delta in price reflects real engineering work.

OEM partnerships work differently too. If you’re integrating generators into your own products, manufacturers adjust pricing based on volume commitments and design involvement. Sometimes you get volume discounts; sometimes you absorb engineering costs.

Generator Type Impact on Total Investment

Let’s make this concrete with standby vs prime power generator cost analysis across different scenarios.

Scenario 1: Hospital Backup Power (150 kW, Prime Power Required)

A hospital needs continuous-rated capacity because load-shedding isn’t an option during patient care. They require:

- Prime power generator: ~$55,000-$65,000

- Automatic Transfer Switch (ATS): $3,000-$5,000

- Installation and commissioning: $8,000-$12,000

- Total immediate investment: $66,000-$82,000

- Annual maintenance: $1,500-$2,500

- Estimated 10-year cost: $85,000-$105,000

A standby-rated equivalent would cost 35% less upfront but wouldn’t meet regulatory requirements for continuous-duty backup power.

Scenario 2: Remote Industrial Site (250 kW, Standby Acceptable)

A mining or remote manufacturing facility needs emergency power when the grid fails, but normal operations don’t depend on continuous generation.

- Standby generator: $50,000-$65,000

- Installation on concrete pad: $4,000-$8,000

- Basic control panel: $2,000-$3,000

- Total immediate investment: $56,000-$76,000

- Annual fuel and maintenance: $800-$1,200

- Estimated 10-year cost: $64,000-$84,000

Here, standby equipment makes economic sense.

Here, standby equipment makes economic sense.

This is where diesel generator total cost of ownership thinking separates smart procurement from expensive mistakes. Most buyers focus on purchase price alone.

Fuel consumption varies by load. A 250 kW diesel generator running at 75% load consumes roughly 50 to 60 gallons per hour. Around $3.50 per gallon diesel, that’s $175-$210/hour. Over 500 annual operating hours (reasonable for standby), you’re looking at roughly $87,500-$105,000 in fuel costs annually. Ten years? That’s $875,000-$1,050,000 in diesel alone.

Alternator efficiency directly impacts TCO. Mid-range generators typically run at 0.8 power factor; premium units maintain 0.9+ power factors. Over time, that efficiency difference adds up significantly.

Maintenance and spare parts represent another substantial category. Standard preventive maintenance—oil changes, filter replacements, coolant checks—typically costs $1,500-$3,000 annually depending on runtime and generator class. Major overhauls at 10,000-15,000 operating hours can run $8,000-$20,000.

Installation complexity varies too. A basic installation might cost $5,000-$10,000. A complex installation involving specialized electrical work, redundant systems, or integration into existing infrastructure can easily exceed $25,000-$40,000.

Manufacturer Pricing Tiers and What They Mean

Industrial manufacturers typically organize around three distinct segments:

Premium Tier (Caterpillar, Rolls-Royce/MTU, Cummins): These companies command 15-25% price premiums because they offer global service networks, comprehensive warranties, and proven engineering. You’re paying for the ecosystem—not just the equipment.

Mid-Market Tier (Kohler, Generac industrial division, regional manufacturers): These compete on value. They offer strong quality, reasonable support, and pricing typically 10-15% below premium brands. Often the sweet spot for mid-sized industrial operations.

Budget Tier (Generic imports, smaller regional manufacturers): These offer lowest acquisition costs, sometimes 30-50% below premium pricing. This tier works when you understand the tradeoff: limited warranty periods, challenging parts sourcing internationally, and potential support gaps if the manufacturer exits the market.

Where to position yourself depends on your operational risk tolerance and capital constraints.

Optimizing Generator Costs: Strategic Approaches

Rightsizing remains the single most effective cost optimization. Oversizing by 20% costs money today with no operational benefit. Undersizing creates future problems. Most manufacturers will help calculate your actual load requirements—make them do this rigorously.

Competitive bidding works, but structure it properly. Get detailed specifications in writing first. Then request bids from three qualified manufacturers. This prevents price shopping without apples-to-apples comparison.

Lease versus purchase decisions deserve explicit analysis. Leasing typically works for temporary power needs or operations with unpredictable duty cycles. Long-term stationary installation? Ownership usually wins financially.

Preventive maintenance partnerships lock in service costs and often save 15-20% versus reactive repair expenses. Companies like Tesla Power understand long-term client relationships—they build service packages that align maintenance schedules with your operational requirements, preventing surprises.

Volume relationships matter if you’re operating multiple sites. Ten generators across a regional operation often qualify for manufacturer pricing concessions that individual facility purchases wouldn’t access.

Real Industrial Examples: What Buyers Actually Spend

Data Center in Texas (Backup power, 500 kW, Tier 4 Compliant):

- Equipment: $165,000

- Installation and ATS: $28,000

- Commissioning and testing: $12,000

- Total capex: $205,000

- Annual maintenance: $3,200

- 10-year TCO: $237,000

Manufacturing Plant in Ohio (Prime power, 350 kW, EPA Tier 3):

- Equipment: $95,000

- Infrastructure upgrades: $35,000

- Integration engineering: $18,000

- Total capex: $148,000

- Annual fuel (3,000 hours): $210,000

- Annual maintenance: $4,500

- 10-year TCO: $2,383,000 (dominated by fuel)

Notice the dramatic difference? Prime power changes the financial calculus entirely.

Remote Mining Site in Nevada (Standby, 250 kW, Variable Duty):

- Equipment: $58,000

- Installation: $6,500

- Control system: $4,000

- Total capex: $68,500

- Annual fuel and maintenance: $2,100

- 10-year TCO: $89,500

Industry Standards and Certification Impact

Units certified to ISO 8528 go through load-bank testing that verifies consistent power output. Certification adds $1,500-$3,000 to equipment cost, but it eliminates uncertainty about performance.

EPA Tier 4 Final compliance remains mandatory for new equipment sold in the US. Budget an additional 12-18% for emissions control systems compared to Tier 3 equipment.

CE Marking (European compliance) requires different engineering in some regions. Not all generators sold globally meet both EPA and CE standards with identical configurations.

ISO 9001 manufacturer certification signals quality management processes—it’s not a direct cost factor, but it correlates with equipment reliability.

These certifications aren’t marketing fluff. They represent testing protocols and engineering standards that affect price because they affect what the manufacturer actually delivers.

Frequently Asked Questions About Industrial Generator Costs

Q1: Why does one manufacturer quote $40,000 and another quotes $55,000 for the same kVA rating?

Specification differences matter more than you’d think. Different alternator designs, engine brands, control panel features, and warranty terms all shift pricing. Sometimes the cheaper option uses aluminum windings instead of pure copper in the alternator—a 5-year reliability difference that costs nothing upfront but plenty later.

Q2: Should I always buy the most expensive generator option for reliability?

No. Premium pricing past a certain point reflects brand positioning, not engineering value. Mid-market manufacturers often deliver superior value. What you should prioritize: service network availability, local parts access, and warranty comprehensiveness. Price is important, but it’s one variable among several.

Q3: How does financing affect the total cost of ownership?

Substantially. A $100,000 generator financed over five years at 6% interest costs roughly $1,933/month in payments alone. Over 10 years at 5% interest, financing spreads the capex but increases total interest paid. Compare: $100,000 purchase versus $108,000 financed. If you can pay cash and that cash would otherwise earn minimal returns, purchasing directly wins. If capital is constrained, financing preserves operational flexibility.

Q4: Can I save money by purchasing used industrial generators?

Sometimes, but with caveats. Used equipment priced 40-50% below new might have substantial runtime hours remaining or unknown maintenance history. A used generator with 8,000 operating hours is near major overhaul territory. Request full maintenance records and load-bank testing results before committing. The risk-adjusted savings often shrink once you factor in potential repairs.

Q5: What’s the realistic maintenance cost over a generator’s lifetime?

Budget 8-12% of purchase price annually for standby systems, 15-25% for prime power systems. A $100,000 generator costs $8,000-$12,000/year for maintenance. Over 15 years, that’s $120,000-$180,000. This matters because total cost of ownership often exceeds initial equipment cost by 150-200%.

Conclusion: Making Informed Decisions About Diesel Generator Manufacturing Cost

Industrial diesel generator manufacturing cost realities resist simple answers. Pricing reflects genuine engineering tradeoffs: reliability versus budget, prime power versus standby duty, premium networks versus budget availability.

The buyers who make confident decisions approach this strategically. They calculate their actual power requirements first—not estimates, but engineered calculations. They understand whether prime power or standby duty fits their operations. They evaluate total cost of ownership, not just acquisition price.

Then they bid competitively among qualified manufacturers, knowing that the lowest price often represents genuine value loss, while the highest price frequently reflects brand premium rather than engineering superiority.

When you’re selecting a manufacturer, verify their industrial power generator specifications documentation, check their certification status (ISO 8528, appropriate regional compliance), and assess their local service network depth. Companies like Tesla Power build long-term client relationships by understanding these hidden costs and helping customers navigate the genuine complexity here.

The investment in diesel generator infrastructure is substantial. Get it right by understanding what’s actually driving those price differences—and you’ll manage both immediate budgets and long-term operational costs far more effectively.