The Real Cost of Running Your Backup Power

I remember a facility manager calling me in a panic at 2 PM on a Tuesday. Their primary data center was down. They’d fired up their backup 200kW diesel generator three hours earlier, and it was already burning through fuel at an alarming rate. By day three of the outage, they’d burned through 4,200 liters of diesel—an expense they hadn’t budgeted for. When they finally ran the numbers with me, they realized they’d been running the generator at 100% load when their actual peak demand was only 85 kW. They were severely over-sized.

This scenario plays out constantly across facilities—hospitals, data centers, manufacturing plants, telecommunications hubs. The question “How much fuel does my diesel generator burn?” sounds simple on the surface, but the answer determines whether your backup power plan is financially viable or a budget disaster waiting to happen.

The reality is this: diesel generator fuel consumption varies dramatically based on load, ambient conditions, maintenance, fuel quality, and how the unit is configured. There’s no single answer—but there ARE precise methodologies to calculate yours, and I’ll walk you through them.

Understanding Diesel Generator Fuel Consumption Metrics

Before we talk about numbers, you need to understand how the industry measures consumption. Most people focus on liters per hour or gallons per hour, but that’s only half the story.

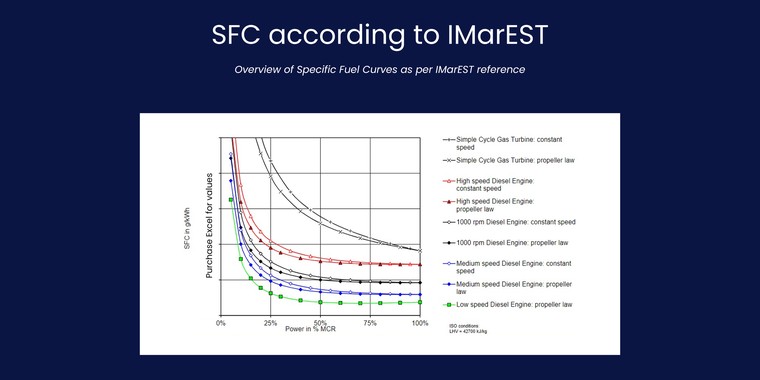

The Core Metric: Specific Fuel Consumption (SFC)

Specific fuel consumption, or SFC, is the industry standard that tells you how many liters of fuel your generator burns to produce one kilowatt-hour of electricity. Think of it as the “miles per gallon” equivalent for power generation.

A typical diesel generator operating at 75% load has an SFC of approximately 0.18 to 0.22 liters per kWh. This means a 100kW generator running at 75% load (75 kW output) would burn roughly 13.5 to 16.5 liters per hour.

Here’s the catch: SFC isn’t constant. It changes based on your diesel generator load factor—the percentage of the generator’s rated capacity at which it’s operating. Run the same generator at 50% load, and the SFC might jump to 0.25 to 0.30 liters per kWh. Run it at 25% load, and it could skyrocket to 0.35+ liters per kWh. This is why idle generators are such fuel hogs.

Why Partial Load is Inefficient

Diesel engines are most efficient when they’re working hard—not idling, not running light. The mechanical and thermal losses in the engine remain relatively constant regardless of load, so those losses become a larger percentage of your power output at lower loads.

Think of it this way: if your generator’s fixed losses (pumps, bearings, cooling system) consume 5 kW no matter what, then at 100% load (80 kW output), those losses represent 6% of your power. At 25% load (20 kW output), those same 5 kW of losses represent 25% of your power. You’re wasting a much larger proportion of the fuel you’re burning.

Critical Factors Affecting Your Real-World Fuel Consumption Rate

Factors beyond just load percentage dramatically shift how much fuel your generator actually burns.

1. Ambient Temperature

Higher ambient air temperature reduces engine efficiency. The inlet air is less dense, the alternator works harder to dissipate heat, and the cooling system demands more power. A generator rated for 300 kW at 25°C (77°F) might only deliver 280 kW at 40°C (104°F)—and that additional stress increases SFC by 3-5%.

2. Altitude

At higher elevations, air density drops, which means less oxygen in each intake stroke. The engine must work harder to produce the same power output. At 2,000 meters (6,600 feet) elevation, you can expect SFC to increase by 5-8% compared to sea level.

3. Fuel Quality & Fuel Quality Diesel Generator Performance

Old, contaminated, or low-cetane fuel forces the injectors to spray fuel less efficiently, reducing combustion completeness. You’ll burn more fuel to produce the same power. Premium diesel (high cetane rating, refined for cold flow) burns cleaner. Budget “red diesel” can have significantly different properties.

4. Maintenance Condition

A clogged air filter forces the engine to work against back pressure. Worn fuel injectors create inconsistent spray patterns. Old oil with elevated viscosity increases friction. A “tired” engine might burn 10-15% more fuel than a well-maintained one.

5. Generator Configuration

Is the cooling system adequate? Is the exhaust unrestricted? Are the belts tight? These details accumulate into measurable efficiency penalties.

Calculating Your Generator’s Actual Fuel Burn Rate

Now, the practical part: calculating your specific scenario. I use this methodology on every engagement.

Step 1: Find Your Generator’s Load-Dependent SFC

Your generator’s manual should include an SFC table or curve. If not, contact the manufacturer with your serial number. The table typically looks like this:

Load %SFC (Liters/kWh)25%0.3250%0.2675%0.20100%0.19

If you don’t have the SFC data, use these diesel generator load factor rules of thumb (these are averages across most modern industrial generators):

- 25% Load: 0.30-0.35 L/kWh

- 50% Load: 0.24-0.28 L/kWh

- 75% Load: 0.18-0.22 L/kWh (most efficient operating zone)

- 100% Load: 0.17-0.21 L/kWh

Step 2: Calculate Your Expected Consumption Rate

Formula: Fuel Burn (Liters/hour) = Generator Capacity (kW) × Expected Load (%) × SFC (L/kWh)

Example: A 100 kW generator running at 75% load

- 100 kW × 0.75 load × 0.20 L/kWh = 15 liters per hour

Step 3: Account for Environmental Derating

If you’re operating outside “standard conditions” (25°C sea level), apply a correction factor:

- High Temperature (+5°C above 25°C): Add 3-5% to SFC

- High Altitude (per 1,000 meters above sea level): Add 2-3% to SFC

- Low Fuel Quality: Add 5-10% to SFC

Revised Example: The same 100 kW generator at 75% load, but operating at 38°C (high ambient) with standard-grade fuel at sea level:

- Base: 15 L/hr

- Temperature correction: 15 × 0.04 (mid-range estimate) = +0.6 L/hr

- Adjusted estimate: 15.6 liters per hour

Step 4: Calculate Fuel Tank Capacity Calculation and Runtime

Now you know your burn rate. How long will your tank last?

Formula: Runtime (hours) = Tank Capacity (Liters) ÷ Fuel Burn Rate (Liters/hour)

If your 100 kW generator has a 2,500-liter tank and burns 15.6 liters per hour at 75% load:

- 2,500 ÷ 15.6 = 160 hours (approximately 6.7 days of continuous operation)

If you’re running at 50% load (lower burn rate of ~12 L/hr):

- 2,500 ÷ 12 = 208 hours (8.7 days)

This is why properly sizing your generator matters. Oversizing gives you longer runtime but lower efficiency and higher fuel costs. Tesla Power and other leading providers now offer load-matching analysis to find the optimal size for your actual facility needs.

Real-World Consumption Benchmarks by Generator Size

While every engine is unique, having a baseline is critical for initial planning. Below are the typical fuel consumption ranges I use when doing rough estimates for clients. These figures assume a standard diesel generator operating at 100% full load.

Generator Size (kW)Fuel Consumption (Liters/hr)Fuel Consumption (Gallons/hr)Estimated Cost per Hour*50 kW14 – 16 L/hr3.7 – 4.2 gal/hr$15 – $17100 kW26 – 30 L/hr6.8 – 7.9 gal/hr$27 – $32200 kW53 – 58 L/hr14.0 – 15.3 gal/hr$56 – $61500 kW130 – 140 L/hr34.3 – 37.0 gal/hr$136 – $147

*Cost estimated based on average market rate of ~$1.05 per Liter ($4.00/gallon).

Pro Tip: Notice how consumption doesn’t scale perfectly linearly? Larger engines often benefit from economies of scale in thermal efficiency, but they also carry heavier parasitic loads.

Strategies to Reduce Fuel Consumption & Optimize Costs

Fuel is usually the single largest lifecycle cost of a generator—often exceeding the purchase price of the unit itself over 10 years. Reducing your burn rate even by 5% adds up to thousands of dollars in savings.

1. Generator Load Optimization

This is the most effective way to save fuel. If you have a 500kW generator but your facility only demands 100kW at night, you are running at 20% load. Your specific fuel consumption metrics are terrible, and you’re wasting fuel.

- Solution: Consider a modular generator setup (paralleling). Instead of one giant 500kW unit, use two 250kW units. At night, you run only one unit at 40-50% load, or better yet, three 150kW units where you can keep the active ones running near that 75-80% efficiency sweet spot.

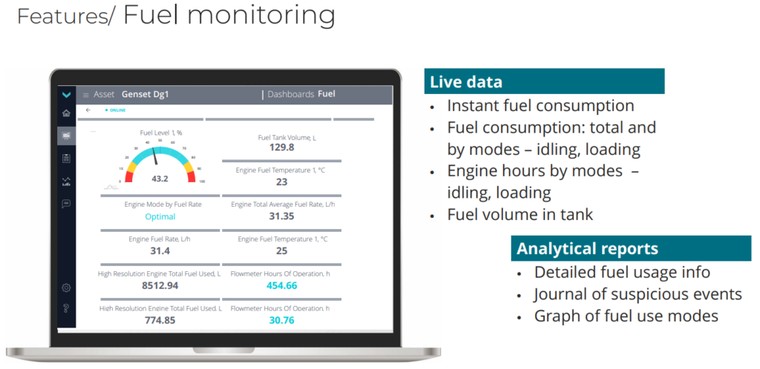

2. Intelligent Monitoring Systems

You can’t manage what you don’t measure. Modern control panels can track instantaneous fuel burn. Industry leaders like Tesla Power provide sophisticated monitoring solutions that overlay your fuel consumption rate against your electrical load in real-time. This allows facility managers to spot inefficiencies—like a generator continuing to run at high idle after utility power has been restored.

3. Preventive Maintenance for Generator Fuel Efficiency

A well-maintained engine burns cleaner. Regular maintenance not only reduces fuel consumption but also extends engine life and prevents catastrophic failures.

- Air Filters: Restrictive airflow forces the engine to work harder to breathe, increasing kW per liter ratio adversely.

- Fuel Injection Timing: If the timing is slightly off, combustion isn’t optimal.

- Belt Tension: Loose fan belts can cause slippage and inefficiency in cooling, forcing the engine to run hotter and less efficiently.

Actionable Checklist: Auditing Your Fuel Strategy

Before your next scheduled maintenance run or storm season, walk through this list:

- Verify Tank Capacity: Don’t trust the manual alone. Physically measure the tank dimensions if possible, or verify with the manufacturer’s specific data sheet for your serial number.

- Calculate Baseline SFC: During your next load bank test, record exact fuel usage over a 1-hour period at 100% load to get your specific baseline.

- Check Fuel Age: If fuel has been sitting for >6 months, test for microbial growth (algae).

- Review Load Profile: Does your generator size match your actual critical load? If you are consistently under-loaded, investigate load optimization or paralleling options.

- Install Flow Meters: For critical facilities, rely on digital fuel flow meters rather than mechanical tank gauges for accuracy. This enables precise diesel generator runtime calculation.

Frequently Asked Questions (FAQ)

1. Does a diesel generator burn fuel when it’s not under load?

Yes. Even with zero electrical load (idling), the engine must burn fuel to overcome internal friction, power the cooling fan, alternator, and oil pump. For a 100kW generator, idle consumption can still be 2-3 liters per hour. This is why minimizing idle time is crucial for generator fuel efficiency. At a facility that idles their backup once a week for testing, you can waste 100+ liters of diesel annually just from idle testing.

2. How much does it cost to run a 20kW diesel generator for 24 hours?

A 20kW generator typically burns about 1.5 to 1.8 gallons (approx. 6-7 Liters) per hour at full load.

- Math: 7 Liters/hr × 24 hours = 168 Liters.

- Cost: 168 Liters ×

$1.05/Liter = **$176.40 for a full day.**

At half load, you might save 30-40% of that cost. Over a year of regular testing, that’s meaningful savings. This is why load-matched sizing matters—you’re paying for every hour, whether you need all that capacity or not.

3. Can I use heating oil instead of diesel to save money?

Technically, many diesel engines can run on heating oil (which is similar to off-road diesel), but it is not recommended for modern standby generators. Heating oil lacks the lubricating additives found in Ultra Low Sulfur Diesel (ULSD), which protects your injectors and fuel pumps. Using it can void warranties and damage expensive components. The cost savings from cheap fuel will be wiped out by injector replacement ($2,000-4,000) and warranty loss.

4. How does the diesel generator load factor impact engine life?

Running with a low load factor (consistently under 30%) causes “wet stacking”—unburned fuel and soot build up in the exhaust. This glazes cylinder liners and reduces engine life. Conversely, running constantly at 110% (overload) causes excessive heat stress. The engine is designed to live happily between 50% and 85% load, where it’s efficient AND mechanically stable. Every hour outside that band chips away at bearing life and seal integrity.

5. Why is my generator burning more fuel than the spec sheet says?

Spec sheets are created in controlled factory conditions (ideal temperature, fresh air, premium fuel). In the real world, factors like high ambient temperatures (air density drops), clogged air filters, old fuel, or high altitude will all negatively impact efficiency. A 5-10% variance from the spec sheet is considered normal operational reality. If you’re seeing 20%+ over spec, that signals maintenance issues—time to bring in a technician to check injector spray patterns, air filter restriction, and fuel quality.