You’re sitting in your office reviewing last quarter’s utility bills when a number catches your eye—your diesel generator fuel expenses jumped 23% during those two extended power outages. The invoices show thousands of dollars spent, but here’s the question that keeps you up at night: are you paying what you should be, or is something burning through your budget?

Understanding how to calculate diesel generator fuel consumption cost per kWh isn’t just about crunching numbers. It’s about taking control of one of your facility’s most unpredictable expenses. When you know exactly what each kilowatt-hour of backup power actually costs you, you can budget accurately, compare generator models on equal footing, and spot inefficiencies before they drain your account.

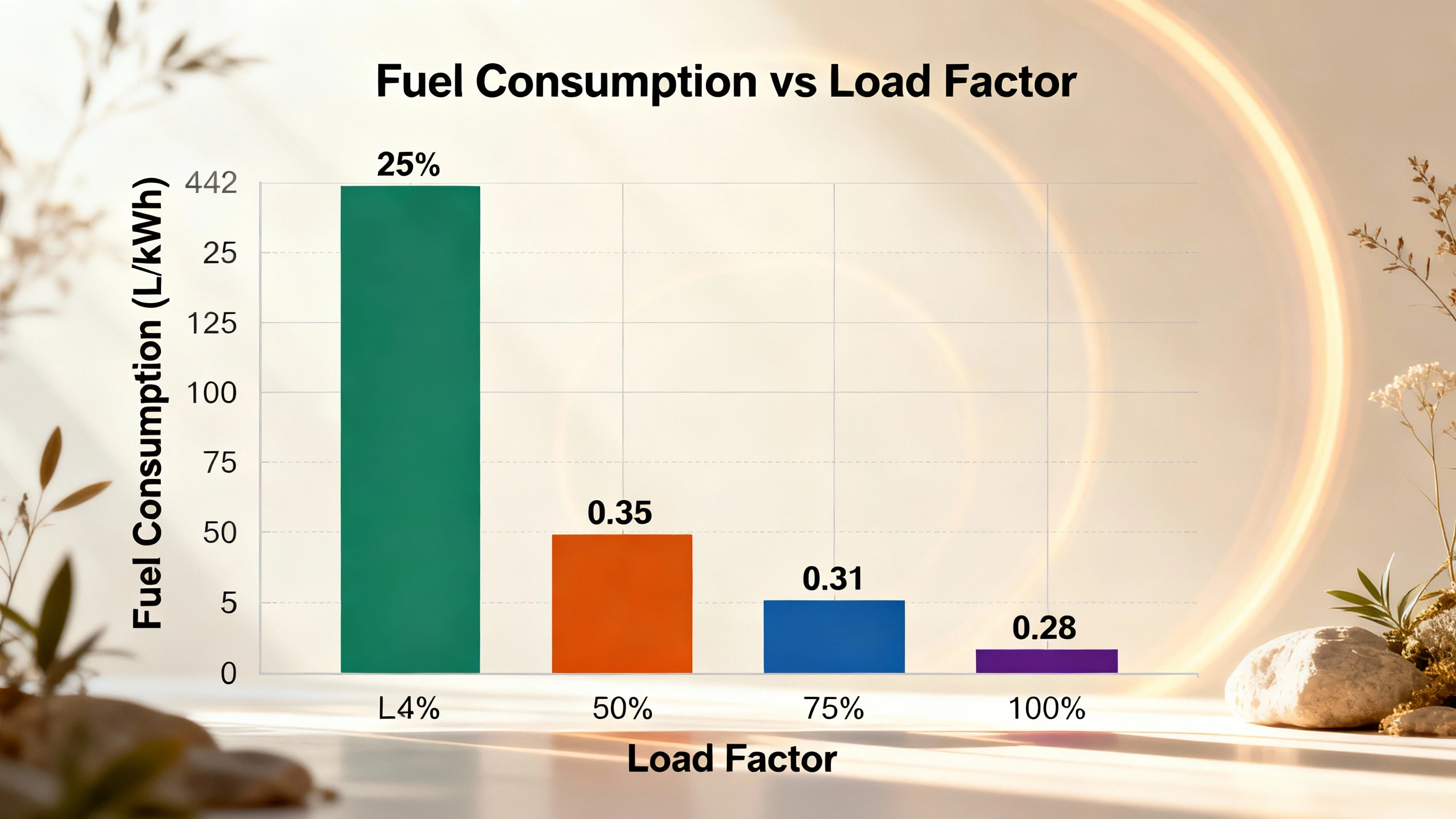

The math itself isn’t complicated—basic arithmetic anyone can handle. But the challenge lies in knowing which variables matter, where to find the right data, and how to account for real-world factors that textbooks don’t cover. A generator running at 25% load burns fuel very differently than one humming along at 75%, and that difference shows up directly in your cost per kilowatt hour.

In this guide, you’ll learn the exact formulas facility managers and power engineers use to calculate diesel fuel cost per kWh. We’ll walk through real examples using actual manufacturer data, show you which factors can double your fuel costs if you’re not paying attention, and share practical strategies that companies like Tesla Power recommend for keeping those expenses under control. Whether you’re evaluating a new generator purchase or trying to understand why your current system costs more to run than expected, you’ll leave with the knowledge to calculate, predict, and optimize your generator operating costs.

Understanding Key Terms: kWh, SFC, Load Factor

Before we dive into calculations, let’s define the terms you’ll encounter in fuel consumption discussions. These aren’t just technical jargon—each one represents a variable that directly impacts what you pay.

What Is a Kilowatt-Hour (kWh)?

A kilowatt-hour is the standard unit for measuring electrical energy. When your generator produces 1 kilowatt of power continuously for one hour, it has generated 1 kWh. Think of it like measuring fuel economy in your car: miles per gallon tells you distance traveled per unit of fuel, while in generators, we flip it around to measure fuel consumed per unit of electrical energy produced.

Your utility bill charges you per kWh for grid power. When your generator takes over during an outage, you’re essentially creating your own kWh—but instead of paying the utility, you’re paying for diesel fuel. The question becomes: what does each of those generator-produced kWh actually cost you?

Specific Fuel Consumption (SFC)

This is the heart of diesel generator fuel consumption calculations. Specific fuel consumption measures how many grams of diesel an engine burns to produce one kilowatt-hour of electricity. It’s expressed as g/kWh—grams per kilowatt-hour.

Why grams instead of liters? Engineers measure SFC by mass because diesel’s density changes with temperature, but mass stays constant. A highly efficient modern generator might achieve 210-220 g/kWh at optimal load, while an older or poorly maintained unit could run at 250-280 g/kWh or higher. That difference matters: a 500 kW generator running for 10 hours at 220 g/kWh burns significantly less fuel than the same generator at 260 g/kWh.

Manufacturers usually list fuel consumption rates in their spec sheets, though you might need to convert from liters per hour to g/kWh. We’ll cover that conversion shortly.

Load Factor: The Hidden Cost Multiplier

Here’s where many people get surprised. Load factor is the percentage of a generator’s rated capacity you’re actually using. If your 400 kW generator is powering 300 kW of equipment, it’s running at a 75% load factor (300 ÷ 400 = 0.75 or 75%).

Why does this matter for fuel costs? Diesel engines are most efficient at moderate-to-high loads, typically 60-80% of their rated capacity. Below that sweet spot, fuel consumption per kWh rises sharply. A generator idling at 25% load might burn 40-50% more fuel per kWh produced compared to the same unit running at 75% load. This is one of the biggest factors in unexpected generator fuel efficiency problems.

Manufacturers like Tesla Power publish fuel consumption curves that show exactly how consumption changes across different load points. These curves aren’t theoretical—they represent real-world performance you can use for accurate cost calculations.

Diesel Fuel Density

One final term: fuel density, typically around 838-850 grams per liter for standard diesel fuel (this is roughly 7 pounds per gallon). You’ll need this number to convert between mass-based consumption figures (g/kWh) and volume-based fuel purchases (liters or gallons). Temperature affects density slightly, but for practical calculations, 838.9 g/L (the value Caterpillar and other manufacturers reference) works well.

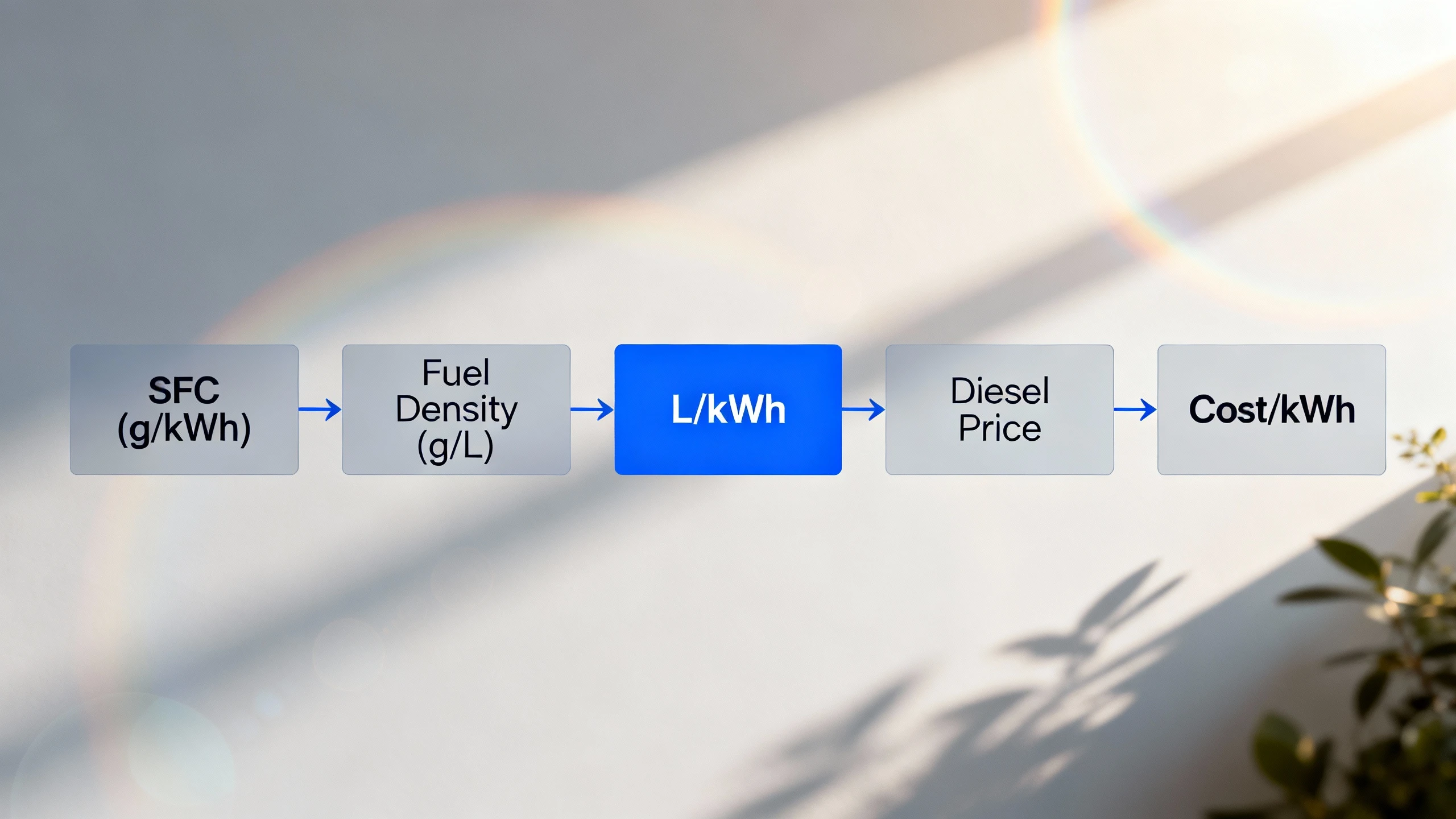

Figure 1: Fuel consumption calculation flowchart showing the conversion from specific fuel consumption (SFC) to cost per kWh. Understanding this formula progression is essential for accurate diesel generator operating cost analysis.

The Basic Fuel Consumption Formula Explained

Now that you understand the terms, let’s look at the core formula for calculating diesel generator fuel consumption cost per kWh. There are two approaches, depending on what data you have available.

Method 1: Using Specific Fuel Consumption (SFC)

If you know your generator’s SFC at a given load, the calculation is straightforward:

Fuel consumed per kWh (in liters) = SFC (g/kWh) ÷ Fuel density (g/L)

Then multiply by your diesel price:

Cost per kWh = (Fuel consumed per kWh) × Diesel price per liter

Let’s plug in real numbers. Suppose your generator has an SFC of 220 g/kWh at 75% load, and diesel costs $1.20 per liter:

- Fuel per kWh = 220 ÷ 838.9 = 0.262 liters/kWh

- Cost per kWh = 0.262 × $1.20 = $0.314 per kWh

So every kilowatt-hour your generator produces costs you about 31 cents in fuel. Compare that to typical grid electricity at $0.10-0.15 per kWh, and you see why backup power is expensive—but during an outage, it’s the only option that keeps your business running.

Method 2: Using Manufacturer Fuel Tables

Many spec sheets don’t list SFC directly. Instead, they provide fuel consumption in liters per hour at different load levels. This method works when you have that data:

Fuel consumption rate (L/kWh) = Fuel consumed per hour (L/h) ÷ Power output (kW)

Then:

Cost per kWh = (Fuel consumption rate) × Diesel price per liter

Example: A Cummins QSZ13 400 kW generator running at 75% load (300 kW) consumes 92 liters per hour according to the datasheet.

- Fuel rate = 92 L/h ÷ 300 kW = 0.307 L/kWh

- Cost per kWh = 0.307 × $1.20 = $0.368 per kWh

Notice this unit shows slightly higher fuel consumption per kWh than the first example—that’s the difference between a highly efficient large industrial generator and a mid-size unit. Both are perfectly functional, but the larger unit offers better fuel efficiency per kWh produced.

Why This Matters for Budgeting

These formulas give you the diesel fuel cost calculation foundation you need. If you know your facility typically runs 150 kW during an outage and your generator consumes 0.30 L/kWh at that load, you can predict costs:

- Hourly fuel consumption: 150 kW × 0.30 L/kWh = 45 liters/hour

- Hourly fuel cost: 45 L × $1.20 = $54/hour

- 24-hour outage cost: $54 × 24 = $1,296

Suddenly those fuel invoices make sense, and you can budget for contingencies with confidence.

Figure 2: Industrial diesel generator installation in a commercial facility. Professional monitoring and proper sizing are critical for optimizing fuel consumption and minimizing operating costs.

Step-by-Step Calculation Guide with Real Examples

Let’s walk through complete calculations using actual generator specifications. These examples mirror what you’d do for your own system.

Example 1: Large Industrial Generator (1500 kW Caterpillar 3512C)

Scenario: Your facility has a Cat 3512C rated at 1500 kW. During a recent 8-hour outage, you ran an average load of 1125 kW (75% load factor). Diesel cost $1.35 per liter. What did those 8 hours cost in fuel?

Step 1: Find the fuel consumption rate from the manufacturer datasheet

According to Caterpillar’s published data, the 3512C consumes 310.5 L/h at 75% load (1125 kW).

Step 2: Calculate fuel consumption per kWh

Fuel rate = 310.5 L/h ÷ 1125 kW = 0.276 L/kWh

Step 3: Calculate cost per kWh

Cost per kWh = 0.276 L/kWh × $1.35/L = $0.373 per kWh

Step 4: Calculate total energy produced

Total kWh = 1125 kW × 8 hours = 9,000 kWh

Step 5: Calculate total fuel cost

Total cost = 9,000 kWh × $0.373/kWh = $3,357

Alternatively, you can calculate directly:

- Total fuel consumed = 310.5 L/h × 8 h = 2,484 liters

- Total cost = 2,484 L × $1.35 = $3,353 (slight difference due to rounding)

Example 2: Mid-Size Standby Generator (400 kW Unit at Variable Load)

Scenario: Your 400 kW generator ran during a 12-hour outage. The load varied: 4 hours at 50% (200 kW), 6 hours at 75% (300 kW), and 2 hours at 25% (100 kW). Diesel cost $1.25 per liter. What’s the total cost?

This requires calculating each load period separately because fuel consumption rate changes with load.

Using typical 400 kW generator fuel data:

- At 100% load (400 kW): 111 L/h → 0.278 L/kWh

- At 75% load (300 kW): 92 L/h → 0.307 L/kWh

- At 50% load (200 kW): 69 L/h → 0.345 L/kWh

- At 25% load (100 kW): 42 L/h → 0.420 L/kWh

Period 1: 50% load for 4 hours

- Fuel consumed: 69 L/h × 4 h = 276 L

- Energy produced: 200 kW × 4 h = 800 kWh

- Cost: 276 L × $1.25 = $345

Period 2: 75% load for 6 hours

- Fuel consumed: 92 L/h × 6 h = 552 L

- Energy produced: 300 kW × 6 h = 1,800 kWh

- Cost: 552 L × $1.25 = $690

Period 3: 25% load for 2 hours

- Fuel consumed: 42 L/h × 2 h = 84 L

- Energy produced: 100 kW × 2 h = 200 kWh

- Cost: 84 L × $1.25 = $105

Total outage cost:

- Total fuel: 276 + 552 + 84 = 912 liters

- Total energy: 800 + 1,800 + 200 = 2,800 kWh

- Total cost: $345 + $690 + $105 = $1,140

- Average cost per kWh: $1,140 ÷ 2,800 kWh = $0.407 per kWh

Notice the average cost per kWh ($0.407) is significantly higher than what you’d get running constantly at 75% load ($0.384). Those 2 hours at 25% load, where the generator burned 0.420 L/kWh, pulled the average up. This illustrates why load factor management matters for cost control.

Example 3: Comparing Two Generator Options

You’re choosing between two 500 kW generators for a facility that typically needs 350 kW during outages (70% load).

Generator A (older model):

- Fuel consumption at 70% load: 140 L/h

- Purchase price: $45,000

Generator B (newer, more efficient model from Tesla Power):

- Fuel consumption at 70% load: 125 L/h

- Purchase price: $58,000

Which is the better investment if you expect 200 hours of operation annually, and diesel costs $1.30/L?

Annual fuel cost comparison:

Generator A: 140 L/h × 200 h × $1.30 = $36,400/year

Generator B: 125 L/h × 200 h × $1.30 = $32,500/year

Annual savings with Generator B: $3,900

Payback period for higher initial cost:

Price difference: $58,000 – $45,000 = $13,000

Payback: $13,000 ÷ $3,900/year = 3.3 years

After 3.3 years, Generator B’s lower fuel consumption pays for its higher purchase price. Over a typical 20-year generator lifespan, you’d save $13,000 + ($3,900 × 16.7 years) = $78,130. This is why generator efficiency calculation should factor into every purchase decision.

Figure 3: Fuel consumption rates at different load factors demonstrating that generators operating at lower loads consume significantly more fuel per kWh. This chart illustrates why maintaining 60-80% load is optimal for fuel efficiency.

Factors That Affect Diesel Generator Fuel Consumption

The formulas we’ve covered give you accurate results—but only if you understand the variables that change fuel consumption in the first place. Here are the factors that can swing your costs by 20-50% or more.

Operating Load (The Dominant Factor)

We’ve touched on this, but it deserves emphasis: load factor is the single biggest variable you control. Running a generator at 25% load can burn 50% more fuel per kWh than running at 75% load. The physics is simple—diesel engines have parasitic losses (friction, pumping air, auxiliary systems) that consume fuel regardless of electrical output. At light loads, those fixed losses represent a larger share of total energy, driving up fuel per kWh produced.

Industry best practice targets 60-80% average load. If your loads consistently fall below 50%, you’re likely oversized, and switching to a smaller generator (or adding a smaller secondary unit for light-load periods) could cut fuel costs dramatically.

Ambient Temperature and Altitude

Diesel engines breathe air, and air density affects combustion. Manufacturer fuel tables assume standard reference conditions—typically 25°C (77°F) at sea level. Operating in hot climates or at high altitude reduces air density, which can increase specific fuel consumption by 3-8% depending on conditions.

If you’re at 1500 meters elevation in a desert climate, expect higher fuel consumption than the datasheet predicts. Manufacturers publish derating curves that quantify this effect. The good news: you can account for it in your calculations once you know your site conditions.

Fuel Quality and Properties

Not all diesel fuel is identical. Biodiesel blends (B5, B10, B20) have lower energy content per liter than pure petroleum diesel, meaning you’ll burn more volume to produce the same kWh. A B20 blend (20% biodiesel) typically has about 2-3% less energy per liter, translating to 2-3% higher volumetric fuel consumption.

Fuel contamination—water, sediment, microbial growth—degrades combustion efficiency and can increase fuel consumption. Regular fuel quality testing and proper storage (clean tanks, water separators, biocide additives if needed) keeps this factor under control.

Generator Maintenance Condition

A poorly maintained generator burns more fuel, period. Dirty air filters restrict airflow, forcing the engine to work harder. Fouled fuel injectors produce poor spray patterns, reducing combustion efficiency. Worn piston rings allow blow-by, wasting compression pressure. Collectively, deferred maintenance can increase fuel consumption by 10-20% compared to a well-maintained unit.

Regular diesel generator maintenance—oil changes, filter replacements, injector cleaning, valve adjustments—isn’t just about reliability. It’s about fuel cost control. The $500 you spend on a scheduled service saves thousands in wasted fuel over the year.

Engine Age and Technology

Modern Tier 4 diesel engines with high-pressure common-rail fuel injection achieve better SFC than older mechanical injection designs. A 15-year-old generator might consume 240-260 g/kWh where a new Tesla Power unit with the latest engine technology achieves 210-220 g/kWh—a 10-15% difference.

This doesn’t mean you should replace a functional older generator immediately, but when budgeting for a new purchase, recognize that fuel savings from newer technology compound over the unit’s lifespan.

Power Factor and Electrical Load Type

Generators are rated in kilowatts (real power), but electrical loads also have reactive power components. Highly inductive loads (motors, transformers) with poor power factor force the alternator to work harder, increasing engine load and fuel consumption beyond what the kW meter indicates.

Maintaining power factor above 0.9 through capacitor correction or efficient equipment keeps fuel consumption aligned with your kW-based calculations. If your power factor drops to 0.7, you might burn 15-20% more fuel than predicted from kW load alone.

Tools and Technologies for Tracking Fuel Costs

Calculating fuel consumption once is useful. Tracking it continuously transforms that calculation into actionable cost management. Here are the tools professionals use.

Generator Controller Telemetry Systems

Modern generator controllers do more than start and stop the engine. Units like the Caterpillar EMCP 4.4, Cummins PowerCommand, and similar systems from manufacturers like Tesla Power continuously monitor and log operational data:

- Real-time kW output

- Running hours at various load levels

- Fuel flow rate (if equipped with fuel sensors)

- Cumulative kWh produced

- Engine parameters (RPM, temperature, pressure)

Many controllers include Ethernet or cellular connectivity, sending data to cloud-based monitoring platforms. You can log into a dashboard from anywhere and see exactly how much fuel you’re consuming per kWh in real time. Some systems even calculate cost per kWh automatically if you input your current diesel price.

Fuel Flow Meters and Tank Level Monitoring

For precise measurement, install a fuel flow meter between the tank and engine. These devices measure actual fuel volume consumed, eliminating estimation errors. Pair it with your controller’s kWh data, and you have perfect fuel consumption rate tracking.

Tank level monitors with ultrasonic or pressure sensors provide a simpler alternative. By comparing tank levels before and after generator runs with the kWh produced, you get consumption figures accurate enough for cost analysis—though not as precise as direct flow measurement.

SCADA and Building Management Systems (BMS)

Large facilities often integrate generator monitoring into their SCADA or BMS platforms. This consolidates generator data with overall facility energy management, enabling:

- Automated fuel cost reporting

- Load profile analysis to identify efficiency opportunities

- Alerts when fuel consumption per kWh exceeds thresholds (indicating maintenance needs)

- Integration with fuel delivery scheduling

These systems are especially valuable when you’re running multiple generators or managing several facilities—centralized data makes diesel fuel cost calculation and comparison straightforward.

Planning and Optimization Software

For pre-purchase analysis or system design, software tools like HOMER Energy model generator fuel curves with detailed load profiles. You input fuel consumption data points (from manufacturer specs), your expected load patterns, and diesel prices. The software calculates projected annual fuel costs, compares multiple generator options, and optimizes sizing.

Spreadsheet models work too. Build a simple calculator with your generator’s fuel table data, input variable loads and fuel prices, and you can scenario-test different operating strategies or compare equipment options before spending a dollar.

Manufacturer Datasheets and Fuel Consumption Charts

Don’t overlook the basics. Every reputable manufacturer publishes detailed fuel consumption tables in their technical documentation. Caterpillar, Cummins, Tesla Power, and others provide load-vs-fuel curves tested under ISO standard conditions. These are your starting point for any calculation.

Industry reference charts—available from sources like Generator Source or similar aggregators—provide benchmark consumption figures by generator size when you don’t have model-specific data. While less precise, they’re useful for preliminary budgeting.

Figure 4: Modern generator control panel displaying real-time fuel consumption metrics and power output. Advanced telemetry systems enable continuous cost tracking and early detection of efficiency problems.

How to Reduce Fuel Consumption and Lower Costs

Understanding fuel costs is step one. Step two is bringing those costs down. Here are proven strategies for improving generator fuel efficiency and cutting your generator operating costs.

Right-Size Your Generator (or Add a Smaller Unit)

If you’re consistently running below 50% load, you’re burning money. An oversized generator wastes fuel during every hour of operation. Two solutions:

- Replace with a properly sized unit. If your actual loads average 200 kW and you’re running a 500 kW generator, downsize to a 300 kW unit. You’ll operate at 65-70% load—right in the efficiency sweet spot—and slash fuel costs.

- Install a smaller secondary generator. Keep the large unit for peak loads but run the smaller one during light-load periods. A facility needing 400 kW during full operations but only 100 kW overnight could run a 150 kW unit after hours, cutting fuel costs by 30-40% compared to running the 500 kW unit at 20% load.

Implement Load Management and Load Shedding

Not every electrical load is equally critical. During generator operation, identify and shed non-essential loads:

- Reduce HVAC setpoints (heating down a few degrees, cooling up a few degrees)

- Delay energy-intensive processes (industrial equipment cycles, charging systems) until grid power returns

- Turn off decorative lighting, vending machines, and convenience loads

Even a 15% reduction in electrical demand translates directly to 15% less fuel consumed. In a 24-hour outage at $60/hour fuel cost, that’s $216 saved with virtually no effort.

Maintain Your Generator Religiously

We mentioned this under factors, but it’s worth repeating as an optimization strategy. A maintenance program that includes:

- Air filter replacement every 500-1000 hours (or annually)

- Fuel filter replacement per manufacturer schedule

- Oil changes with quality lubricants

- Fuel injector cleaning every 2-3 years

- Regular load bank testing to clear carbon buildup

…can reduce fuel consumption by 10-15% compared to a neglected unit. Over a generator’s 20-year lifespan, that’s tens of thousands of dollars in savings. Facilities using Tesla Power generators report excellent long-term efficiency when following recommended maintenance intervals.

Optimize Power Factor

If your facility has significant motor loads, install power factor correction capacitors. Improving power factor from 0.75 to 0.95 can reduce generator fuel consumption by 10-15% while powering the same equipment. This is especially valuable for manufacturing facilities, data centers with large UPS systems, and operations with numerous motors or transformers.

Use High-Quality Fuel and Additives

Premium diesel with higher cetane ratings (48-52 vs. minimum 40) burns more completely and efficiently. The fuel may cost 2-3% more per gallon, but you’ll see 1-2% better fuel economy—nearly break-even, plus the benefit of cleaner combustion and less engine wear.

Fuel stabilizers and biocide additives prevent degradation and contamination in stored fuel, maintaining peak combustion efficiency. These are especially important if you store fuel for extended periods between outages.

Track, Measure, and Adjust

You can’t optimize what you don’t measure. Use the monitoring tools we discussed to track your actual fuel consumption per kWh over time. When you see consumption creeping up, investigate:

- Has maintenance been deferred?

- Has your load profile changed?

- Is fuel quality suspect?

- Are ambient conditions (temperature, altitude) different from baseline?

One facility discovered their fuel consumption increased 18% over six months. Investigation revealed a partially clogged air filter that had been missed during a rushed service. Replacing it immediately restored normal efficiency—but without measurement, the problem would have persisted for months, wasting thousands of dollars.

Consider Hybrid Systems or Load-Following Controls

Advanced installations pair generators with battery energy storage systems. The battery handles short-term loads and transients while the generator runs at optimal load when engaged. This keeps the diesel engine in its efficient operating range and can cut fuel costs by 20-30% in variable-load applications.

Load-following controls (also called isochronous governors) automatically adjust engine speed and fuel delivery to match electrical demand precisely, rather than running full-speed regardless of load. While most standby generators don’t have this feature, prime power and continuous-duty units often do, offering fuel savings in variable-load scenarios.

Conclusion: Taking Control of Your Generator Operating Costs

Calculating diesel generator fuel consumption cost per kWh doesn’t require advanced engineering—just the right formulas, accurate data, and an understanding of what drives those numbers up or down. Whether you’re using manufacturer fuel tables or real-world telemetry from your controller, the basic math is straightforward: liters per kWh times your diesel price equals your true cost of backup power.

But the real value isn’t in the calculation itself. It’s in what you do with that information. When you know your generator burns 0.30 L/kWh at 70% load but 0.42 L/kWh at 25% load, you can make informed decisions about load management, sizing, and when to shed non-critical loads. When you track consumption over time and notice a 12% increase, you can investigate maintenance issues before they cost you thousands in wasted fuel.

The examples we walked through—from the 1500 kW industrial unit to the payback analysis comparing two 500 kW models—show how these calculations apply to real purchasing and operational decisions. A few percentage points in fuel efficiency might not sound dramatic, but compounded over thousands of operating hours and a 20-year lifespan, those differences represent significant money.

Manufacturers like Tesla Power design their systems with these economics in mind, publishing detailed fuel consumption data and building in monitoring capabilities that help you track costs in real time. Take advantage of those tools. Build a simple spreadsheet or use your controller’s telemetry. Run the numbers before you buy, and track them while you operate.

Your backup power system is an insurance policy that occasionally becomes your entire electrical supply. Understanding what it costs to run—per kilowatt-hour, per hour, per outage—transforms it from an unpredictable expense into a manageable, optimizable part of your operational budget. That’s the difference between reacting to surprise fuel bills and proactively controlling one of your facility’s most important systems.

Frequently Asked Questions

Q1: What is the average fuel consumption for a diesel generator per kWh?

The average fuel consumption typically ranges from 0.27 to 0.35 liters per kWh for well-maintained industrial diesel generators operating at optimal load (60-80% capacity). Highly efficient large generators (1000+ kW) can achieve 0.26-0.27 L/kWh at full load, while smaller units (100-500 kW) typically consume 0.28-0.32 L/kWh. However, consumption increases significantly at lighter loads—a generator running at 25% capacity might burn 0.40-0.50 L/kWh, which is why proper sizing and load management are crucial for controlling fuel costs.

Q2: How do I find my generator’s specific fuel consumption rate?

Check your generator’s technical datasheet or operator manual, which should include a fuel consumption table showing liters per hour at different load percentages (25%, 50%, 75%, 100%). Divide the fuel rate by the corresponding kW output to get L/kWh. For example, if your 400 kW generator consumes 92 L/h at 75% load (300 kW), the consumption rate is 92 ÷ 300 = 0.307 L/kWh. If you can’t find manufacturer data, install a fuel flow meter or monitor tank levels before and after operation to measure actual consumption, then divide by the kWh your generator controller records.

Q3: Why does my generator consume more fuel than the datasheet predicts?

Several factors can increase actual fuel consumption beyond manufacturer specifications. The most common cause is operating at low load factors—running a generator well below its rated capacity dramatically increases fuel consumption per kWh. Other factors include deferred maintenance (dirty air filters, worn injectors, degraded oil), high ambient temperature or altitude (reduces air density), contaminated or low-quality fuel, poor power factor from inductive loads, and aging engine technology. If your consumption has increased over time, start by checking maintenance items like filters and conducting a load profile analysis to ensure you’re operating in the efficient 60-80% load range.

Q4: How much does it cost to run a diesel generator for 24 hours?

The cost depends on three variables: your generator’s size, the actual load you’re running, and your diesel fuel price. Here’s a practical example: A 500 kW generator running at 70% load (350 kW) with a fuel consumption rate of 0.30 L/kWh will consume 350 kW × 0.30 L/kWh = 105 liters per hour. At $1.25 per liter, that’s $131.25 per hour, or $3,150 for 24 hours. A smaller 200 kW unit at the same load factor might cost $1,200-1,500 per day, while a large 2000 kW industrial generator could exceed $10,000 per day. Use the formulas in this guide with your specific generator’s fuel data to calculate your exact costs.

Q5: Can I reduce my diesel generator fuel costs without replacing the equipment?

Absolutely. The most effective strategies include: (1) Optimizing load factor by shedding non-essential loads during generator operation—even a 15% load reduction cuts fuel costs by 15%; (2) Following a rigorous maintenance schedule—clean filters, quality oil, and properly functioning injectors can improve fuel efficiency by 10-15%; (3) Improving power factor through capacitor banks if you have motor-heavy loads; (4) Using fuel additives and quality diesel to maintain combustion efficiency; (5) Installing telemetry and monitoring systems to track consumption and spot problems early. For facilities with highly variable loads, adding a smaller secondary generator for light-load periods can cut fuel costs by 30-40% compared to running an oversized primary unit continuously.