When you’re looking to source a diesel generator from China, the stakes are high. Get it right, and you’ll secure reliable power at a competitive price. Get it wrong, and you might end up with equipment that fails when you need it most—or worse, a complete scam.

I’ve worked with dozens of buyers over the years who’ve navigated this exact challenge. Some walked away with exceptional partnerships that saved their companies hundreds of thousands of dollars. Others learned expensive lessons about cutting corners on supplier vetting.

The good news? Choosing a reliable diesel generator manufacturer in China doesn’t have to be a gamble. With the right framework and a clear understanding of what to look for, you can identify trustworthy partners who’ll deliver quality equipment on time and on budget.

Let me walk you through exactly how to do it.

Understanding the Chinese Diesel Generator Manufacturing Landscape

Before we jump into the selection criteria, it helps to understand what you’re working with.

China produces roughly 60% of the world’s diesel generators. The manufacturing ecosystem ranges from world-class facilities that supply Fortune 500 companies to small workshops churning out low-grade equipment. This vast spectrum means you have incredible opportunities—but also significant risks.

The industrial diesel generator market in China clusters around several key manufacturing hubs: Fujian Province (particularly Fuzhou and Quanzhou), Jiangsu Province (Wuxi and Yangzhou), and Guangdong Province (Guangzhou and Shenzhen). Each region has developed specialized expertise over decades.

What separates the reliable manufacturers from the rest? Let’s break it down.

Key Factors That Define a Reliable Manufacturer

Manufacturing Certifications and Quality Standards

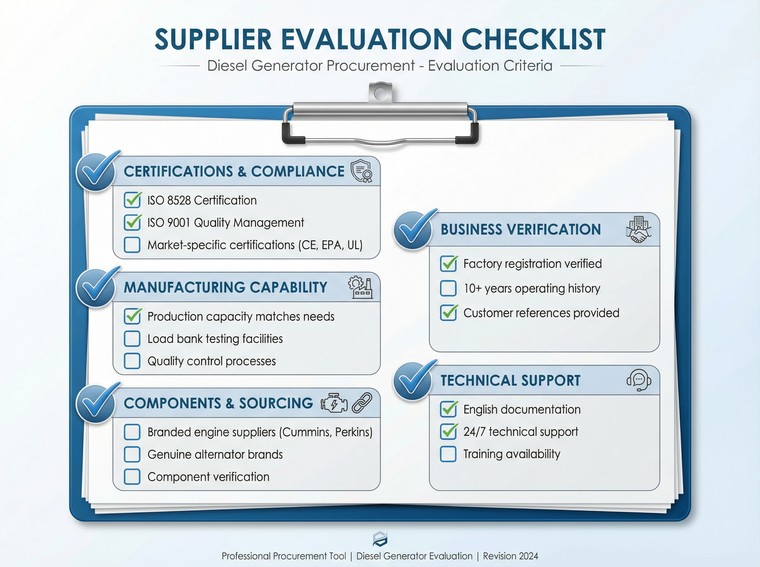

Certifications aren’t just paperwork—they’re proof that a manufacturer has submitted to independent audits and testing.

ISO 8528 certification is the international standard for reciprocating internal combustion engine-driven alternating current generating sets. When a Chinese diesel generator factory holds this certification, it means their products meet specific requirements for performance, safety, and testing protocols.

But here’s the catch: not all ISO certificates are created equal. I’ve seen manufacturers display certificates that were purchased from dubious certification mills. Always verify certifications directly with the issuing body. Legitimate manufacturers will happily provide you with certificate numbers you can verify online.

Look for these essential certifications:

- ISO 9001 (Quality Management Systems)

- ISO 14001 (Environmental Management)

- CE marking (for European markets)

- EPA Tier 4 or equivalent emission standards

- UL listing (if targeting North American markets)

Manufacturers like Tesla Power maintain multiple international certifications and regularly update them, which demonstrates ongoing commitment to quality standards rather than one-time compliance.

Production Capacity and Scale

Size matters, but not always in the way you’d think.

Large manufacturers with production capacities exceeding 10,000 units annually typically offer better economies of scale, more sophisticated quality control systems, and greater financial stability. They’re less likely to disappear overnight or struggle to fulfill large orders.

However, mid-sized specialized manufacturers (producing 1,000-5,000 units annually) can offer advantages too: more flexible customization, faster response times, and often more direct communication with decision-makers.

The real question: does their capacity match your needs? A manufacturer producing primarily small portable generators may not be your best choice for a 2000 kW standby power solution for a data center, even if they claim they can handle it.

Ask specific questions:

- What’s your monthly production capacity for generators in my power range?

- What percentage of your production goes to export markets?

- Who are your three largest customers? (Reputable manufacturers serving major brands is a positive signal)

- Can I see your production schedule for the next quarter?

Component Sourcing and Engine Partnerships

Here’s something many buyers overlook: the engine typically represents 40-60% of a generator’s total cost and determines much of its reliability.

Top-tier Chinese diesel generator manufacturers don’t make their own engines—they partner with proven engine brands. Look for generators powered by:

- Cummins (US/China joint ventures)

- Perkins (UK, now part of Caterpillar)

- Deutz (Germany)

- Volvo Penta (Sweden)

- MTU (Germany, for large industrial applications)

Similarly, alternators should come from established brands like Stamford, Marathon, or Leroy-Somer.

A diesel genset manufacturer assembling proven components demonstrates wisdom and specialization. They’re focusing on what they do best: engineering the integration, control systems, cooling, and overall package—rather than trying to do everything in-house.

Red flag: manufacturers who claim their proprietary engines are “just as good” as established brands at half the price. Maybe they are, but you’ll have no independent performance data and uncertain spare parts availability five years from now.

Quality Control Processes

Walk through the quality control (QC) process with any potential supplier. Reliable manufacturers will enthusiastically describe their multi-stage inspection protocols.

Factory acceptance testing (FAT) should be standard. This means every generator undergoes full-load testing before shipment. Not just a quick startup test—actual sustained operation at 100% rated load for several hours to verify all specifications.

Look for manufacturers with:

- Incoming component inspection (verifying supplier quality)

- In-process inspection points (catching issues during assembly)

- Pre-delivery testing (full load bank testing)

- Test certificates provided with each unit

Tesla Power, for example, operates a dedicated testing facility with load banks up to 5000 kW, allowing them to fully test even their largest generators under real operating conditions before shipping.

Technical Support and Documentation

You’re not just buying a generator—you’re entering a relationship that will last 15-20 years or more.

Quality manufacturers provide comprehensive technical documentation in English:

- Detailed operation and maintenance manuals

- Electrical schematics and control panel diagrams

- Parts catalogs with exploded views and part numbers

- Troubleshooting guides

- Maintenance schedules

They should also offer:

- Responsive technical support (ideally 24/7 for critical applications)

- Training for your maintenance team (in-person or virtual)

- Remote diagnostics capabilities for modern generators with telemetry

- Video call support for troubleshooting

I once worked with a buyer who chose a manufacturer solely based on price. When they needed support six months later, they discovered the “technical team” was one person who spoke limited English and was only available during Chinese business hours. The generator sat idle for three weeks during the height of summer. Don’t let that be you.

The Due Diligence Process: Step-by-Step

Now that you know what to look for, here’s your practical roadmap for vetting potential manufacturers.

Step 1: Initial Research and Shortlisting

Start with 8-10 potential manufacturers. Use multiple sources:

- Industry trade shows (Canton Fair, Bauma China, Power-Gen Asia)

- B2B platforms like Alibaba and Made-in-China (but verify everything independently)

- Industry associations and trade directories

- Referrals from other buyers in your industry

Create a shortlist of 3-4 manufacturers based on your initial research into their certifications, product range, and company history.

Step 2: Request Detailed Quotations and Technical Specifications

Don’t just ask for a price. Request comprehensive quotations that include:

- Complete technical specifications matching your requirements

- Component brands and models (engine, alternator, control panel, etc.)

- Certifications applicable to your market

- Warranty terms (and what they actually cover)

- Delivery timeline and shipping method

- Payment terms

Compare quotations side-by-side. Significant price differences usually indicate differences in component quality or included features, not just profit margins.

Step 3: Verify Company Credentials

This is where many buyers skip steps—don’t.

- Verify business registration through China’s National Enterprise Credit Information Publicity System

- Check how long they’ve been in business (look for 10+ years of operating history)

- Search for any legal disputes or negative news

- Verify physical factory address (not just a trading company office)

- Check if they’re a manufacturer or trading company (both can be legitimate, but you should know which you’re dealing with)

Step 4: Conduct Factory Audits

Nothing replaces seeing the factory yourself. If budget allows, visit in person. If not, arrange a comprehensive video tour.

What to examine during a factory audit:

- Production floor cleanliness and organization

- Testing equipment and procedures

- Component inventory and storage conditions

- Employee training and safety protocols

- Quality control checkpoints

- Shipping and packaging processes

Ask to see generators in various stages of production. A real manufacturer will have multiple units in progress, not just finished units waiting for shipment.

Many manufacturers now offer virtual factory tours via video call. While not as thorough as in-person visits, a well-conducted virtual tour can reveal a lot. Pay attention to whether they’re willing to show you all areas or just a polished showroom.

Step 5: Request and Check References

Ask for references from customers in your region or industry. Then actually contact them.

Questions to ask references:

- How long have you been working with this manufacturer?

- Have you experienced any quality issues? How were they resolved?

- How responsive is their technical support?

- Have deliveries met promised timelines?

- Would you buy from them again?

A manufacturer confident in their product will readily provide multiple reference contacts. Hesitation is a red flag.

Step 6: Order a Sample or Trial Unit

For significant procurement, consider ordering a single unit for testing before committing to a large order.

Yes, this adds time and cost upfront. But discovering problems with one generator is infinitely better than discovering them with fifty.

Test the sample unit thoroughly:

- Verify all technical specifications match the promised performance

- Run extended load tests (if possible, mirror your actual application)

- Evaluate noise levels, vibration, and emissions

- Test all control and safety features

- Examine build quality and component brands

- Assess documentation quality

Common Red Flags to Watch For

Even with careful vetting, scammers and low-quality manufacturers will try to win your business. Here are the warning signs I’ve learned to spot:

Prices significantly below market rates – If it seems too good to be true, it almost certainly is. Quality diesel generators have real cost floors determined by component prices. Quotes 30%+ below competitors usually mean inferior components or corners cut elsewhere.

Reluctance to provide verifiable information – Legitimate manufacturers are proud of their certifications, references, and facilities. If a supplier becomes evasive when you ask for details or verification, walk away.

Pressure tactics – “This price is only good for 24 hours” or “We have many other buyers interested” are classic pressure tactics. Professional manufacturers provide reasonable time to make informed decisions.

Poor communication – If communication is difficult during the sales process, it will only get worse after you’ve paid. Look for responsive, clear communication in your language.

Unwillingness to customize payment terms – While Chinese manufacturers typically prefer payment terms favorable to them, reputable ones understand international trade norms. Absolute refusal to consider letters of credit or escrow arrangements for first-time buyers is suspicious.

No physical factory – Some trading companies present themselves as manufacturers. Trading companies aren’t inherently bad—some provide valuable services—but you should know what you’re working with and price accordingly.

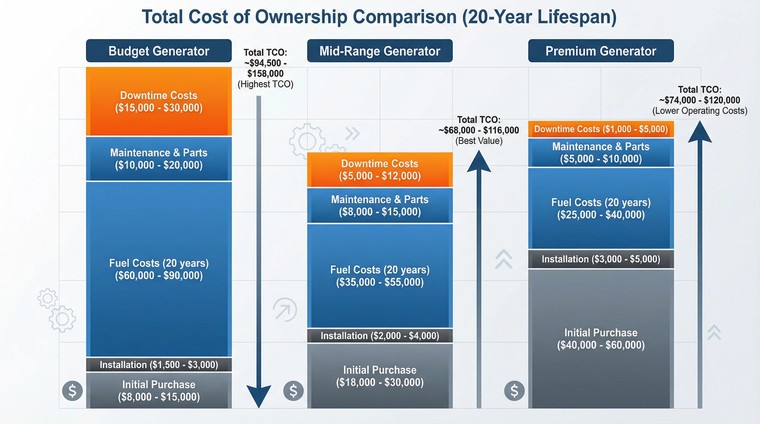

Understanding Total Cost of Ownership

The purchase price is just the beginning. Smart buyers evaluate the total cost of ownership (TCO) over the generator’s expected 20-year lifespan.

TCO includes:

- Initial purchase price

- Shipping and import duties

- Installation and commissioning

- Fuel consumption (this is huge—generator fuel efficiency varies significantly)

- Maintenance and parts over the lifespan

- Downtime costs if reliability is poor

- Eventual disposal or resale value

A generator that costs $30,000 but consumes 20% more fuel than a $35,000 alternative will cost you more over ten years of operation. Run the numbers.

Also consider OEM vs aftermarket parts availability. A manufacturer that uses proprietary components might lock you into expensive parts with limited availability. Generators built with common components from major suppliers offer more flexibility and often lower maintenance costs.

Working with Manufacturers vs. Trading Companies

You’ll encounter both manufacturers and trading companies when sourcing from China. Each has advantages.

Direct from manufacturer:

- Better pricing (no middleman markup)

- Direct technical support

- Greater customization possibilities

- Building direct relationships

Through trading companies:

- Simplified communication (many have native English speakers)

- May handle logistics and documentation more smoothly

- Can source from multiple manufacturers if you have varied needs

- Sometimes provide additional quality oversight

Neither is inherently better. The key is knowing which you’re working with and setting expectations accordingly. If you’re working with a trading company, ask them to disclose the actual manufacturer so you can verify factory credentials.

Building Long-Term Partnerships

The best manufacturer relationships extend far beyond a single transaction.

Once you’ve identified a reliable Chinese diesel generator supplier, invest in the relationship:

- Visit regularly (if possible) to maintain personal connections

- Provide feedback on product performance and areas for improvement

- Pay on time and honor your commitments

- Consider them for future projects and different equipment needs

- Understand that Chinese business culture values long-term relationships—manufacturers often provide better service and pricing to established customers

Manufacturers like Tesla Power often assign dedicated account managers to regular customers, providing continuity and familiarity with your specific needs and preferences.

Tools and Resources for Supplier Verification

Several tools can help you verify manufacturer credibility:

Alibaba’s Trade Assurance – Provides some payment protection and dispute resolution for transactions conducted through their platform.

SGS or Bureau Veritas Inspections – Third-party inspection services can conduct factory audits and pre-shipment inspections on your behalf.

China Checkup or V-Trust – Specialized services that verify Chinese suppliers and conduct factory audits.

TradeKey and Global Sources – Alternative B2B platforms with manufacturer listings and verification services.

LinkedIn – Research the manufacturer’s employees and leadership. Real companies have real people with professional profiles.

Don’t rely on any single verification method. Layer multiple approaches to build confidence.

Real-World Example: A Procurement Success Story

Let me share a case that illustrates these principles in action.

A hospital network in East Africa needed five 500 kW diesel generators for backup power across their facilities. Their budget was tight, but reliability was non-negotiable—lives literally depended on uninterrupted power.

Their procurement manager spent six weeks on the vetting process:

- Shortlisted four manufacturers based on certifications and references

- Requested detailed quotations with full specifications

- Conducted virtual factory tours with all four

- Checked references for the top two candidates

- Visited China to tour both factories in person

- Negotiated a sample order for one unit with extended testing

They ultimately chose a mid-sized manufacturer (not the cheapest, not the most expensive). The sample generator performed flawlessly through three months of testing. They placed the order for the remaining four units.

Three years later, all five generators have performed reliably with minimal maintenance. The manufacturer has provided responsive support for the few minor issues that arose. Total cost of ownership has tracked below their projections due to excellent fuel efficiency and minimal downtime.

The procurement manager told me: “Spending those six weeks upfront saved us from years of potential problems. The peace of mind was worth every hour.”

Common Mistakes Buyers Make

Learn from others’ mistakes:

Focusing only on price – The cheapest option almost never delivers the best value. Focus on total cost of ownership and reliability.

Skipping factory verification – Accepting a supplier’s claims without independent verification is risky. Always verify.

Inadequate contractual protections – Work with legal counsel familiar with international trade to ensure your contract protects your interests, especially regarding warranties, delivery terms, and dispute resolution.

Ignoring after-sales support – Technical support and parts availability matter as much as initial quality. Evaluate these factors carefully.

Rushing the decision – Supplier selection deserves significant time and attention. Rushing leads to poor choices.

Not planning for logistics – Understanding shipping, customs, and local installation requirements prevents surprise costs and delays.

Frequently Asked Questions

How long does it typically take to vet and select a reliable diesel generator manufacturer in China?

Plan for 6-12 weeks for a thorough vetting process. This includes initial research (1-2 weeks), requesting and comparing quotations (1-2 weeks), verifying credentials and conducting audits (2-4 weeks), checking references (1 week), and potentially testing a sample unit (2-4 weeks). Rushing this process increases risk significantly. For ongoing procurement relationships, the upfront investment pays dividends for years.

Can I trust certifications displayed on manufacturer websites?

View website certifications as starting points, not proof. Always verify certifications independently by contacting the issuing body directly with the certificate number. ISO certifications can be verified through registrars like SGS, Bureau Veritas, or TÜV. CE markings should have notified body numbers you can verify. Reputable manufacturers will provide all information needed for verification. Reluctance to share verifiable details is a red flag.

What’s a reasonable price range for industrial diesel generators from China?

Prices vary widely based on power output, component quality, and features. As a rough guide, quality industrial diesel generators from reputable Chinese manufacturers typically cost $50-100 per kW for smaller units (under 500 kW) and $40-80 per kW for larger units (500 kW+). Prices significantly below these ranges likely indicate lower-quality components or less stringent manufacturing standards. Always compare similar specifications—an apples-to-apples comparison.

Should I work with a trading company or direct with a manufacturer?

Both can work well depending on your situation. Direct manufacturer relationships typically offer better pricing and direct technical support, ideal if you have the resources to manage international procurement. Trading companies add costs but may simplify communication, logistics, and multi-product sourcing. They can also provide valuable local expertise. The key is transparency—know who you’re working with and verify the actual manufacturer’s credentials regardless.

How can I protect myself from scams when sourcing from China?

Use multiple protective layers: Verify the company’s legal registration and physical factory location. Check references from other international buyers. Use secure payment methods like letters of credit or escrow services for first-time transactions. Consider third-party inspections before shipment. Never pay full amounts upfront. Be wary of deals that seem too good to be true. Work with legal counsel experienced in international trade. Trust your instincts—if something feels off, investigate further or walk away.

Taking the Next Step

Choosing a reliable diesel generator manufacturer in China requires diligence, but it’s far from impossible. With the framework outlined here, you’re equipped to separate the trustworthy manufacturers from the rest.

Start by clearly defining your requirements—power output, duty cycle, emission compliance standards, and any special features. Then begin your research with the criteria we’ve covered. Take your time, verify everything, and don’t let price alone drive your decision.

The right manufacturer will welcome your questions, provide transparent information, and demonstrate genuine interest in meeting your needs. They understand that their success depends on your success.

When you find that partner, you’re not just buying equipment—you’re building a relationship that can serve your power needs reliably for decades to come.