Picture this: you’ve just invested $25,000 in a shiny new diesel generator, only to discover it runs at 20% capacity most of the time—wasting fuel, accumulating carbon, and costing you an extra $2,000 annually in inefficiency. Or worse, you bought too small, and when the power goes out, your critical systems shut down anyway because the generator can’t handle the load.

Sizing a diesel generator isn’t guesswork. Get it wrong, and you’ll pay for that mistake every single hour the unit runs. Get it right, and your generator will deliver reliable backup power efficiently for decades. The difference between these outcomes comes down to four straightforward steps that any facility manager can follow.

Let’s walk through exactly how to size your generator correctly—no engineering degree required.

Why Generator Sizing Is Your Most Critical Decision

Before we dive into the how-to, you need to understand what’s at stake. An undersized diesel generator is the nightmare scenario—your mission-critical equipment shuts down mid-outage because the generator can’t deliver enough power. You’ve essentially bought an expensive paperweight.

But oversizing is the silent budget killer. A generator running consistently below 40% load operates in what engineers call the “wet stacking zone.” Incomplete combustion creates carbon deposits, fouls injectors, and can cut engine life by 30-40%. You’ll burn 25-40% more fuel per kilowatt-hour produced, spend more on maintenance to clean up the carbon mess, and still need to replace the unit sooner.

Tesla Power and other manufacturers consistently report that improper sizing is the #1 cause of premature generator failure and customer dissatisfaction. The few hours you invest in sizing correctly will save you tens of thousands over the generator’s lifetime.

Step 1: Calculate Your Total Power Requirements

Start by listing every piece of equipment that needs power during an outage. I mean everything—HVAC systems, lighting, computers, servers, refrigeration, security systems, medical equipment, manufacturing machinery, you name it.

Identify Running Watts (Continuous Load)

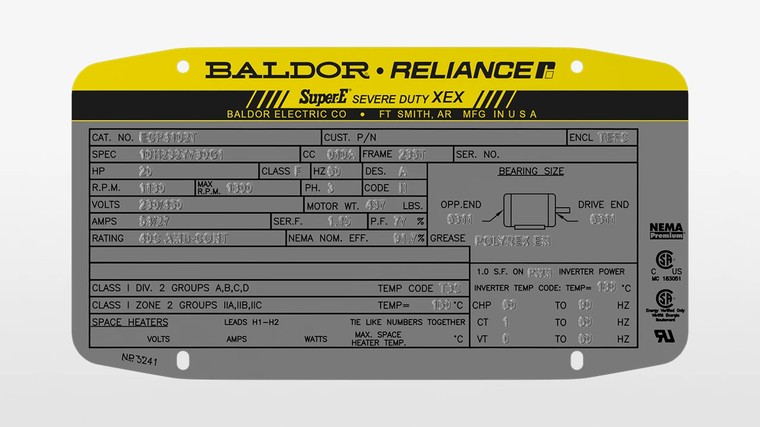

For each device, find its running wattage—the power it consumes during normal operation. Check nameplates, equipment manuals, or use this quick reference:

Office/Commercial:

Desktop computer: 200-400W | LED lighting (per fixture): 10-50W | Laptop: 50-100W | Laser printer: 400-600W | Copier: 1,000-1,500W | Small server: 300-800W | Network equipment: 50-200W

HVAC & Mechanical:

5-ton AC unit: 5,000-6,000W | Furnace blower: 600-1,200W | Sump pump: 800-1,200W | Well pump (1 HP): 1,000-2,000W

Medical/Critical:

Ventilator: 100-200W | Patient monitor: 50-100W | Imaging equipment: varies widely (1,000-10,000W) | Refrigeration (vaccine storage): 300-800W

Industrial:

Conveyor motor (1 HP): 1,000W | Air compressor (5 HP): 4,000-5,000W | CNC machine: 3,000-8,000W

Add up every device you absolutely need during an outage. Don’t pad the numbers yet—we’ll handle safety margins later. For our example, let’s say you’ve calculated 75,000 watts (75 kW) of continuous load.

Step 2: Account for Starting Surge and Motor Loads

Here’s where most DIY sizing attempts fall apart. Motors, compressors, and other inductive loads draw 2-7 times their running wattage for a few seconds during startup. This starting surge can overload an undersized genset even if the continuous load is well within capacity.

Calculate Surge Requirements

For each motor-driven device, multiply its running wattage by its starting surge factor:

Surge multipliers:

Resistive loads (heaters, lights): 1.0x | Small motors (<1 HP): 2-3x | Medium motors (1-5 HP): 3-5x | Large motors (>5 HP): 5-7x | Air compressors: 3-5x | Refrigeration compressors: 2-4x | Submersible pumps: 5-7x

Don’t panic—you won’t start everything simultaneously. This is where load diversity saves you. Identify your largest motor load (let’s say a 5 HP air compressor drawing 25,000W at startup). Your generator must handle your base continuous load plus this peak surge.

In our example: 75 kW continuous + 25 kW peak surge = 100 kW peak demand.

Soft-Start Options

Modern facilities can reduce surge requirements with soft-start controllers or variable frequency drives (VFDs). These devices ramp motors up gradually, cutting starting current by 50-70%. If you’re specifying new equipment or retrofitting existing motors, this is a smart investment that can let you size down your generator by 20-30%.

Companies like Tesla Power offer generators with advanced load management systems that can sequence motor starts automatically, spreading the surge load over time. Worth considering for complex installations.

Step 3: Choose the Right Generator Size and Configuration

Now you’ve got your numbers: 75 kW continuous load and 100 kW peak demand. Time to select your Cummins generator or equivalent.

Apply the Optimal Loading Rule

For standby generators (occasional use), target 70-80% loading at your typical continuous demand. This means your 75 kW continuous load should run on a generator rated for 90-105 kW. A 100 kW unit sits right in that sweet spot.

For prime power applications (continuous or extended runtime), be more conservative: target 60-75% loading. Your 75 kW load would call for a 100-125 kW unit.

Single-Phase vs. Three-Phase

Small facilities with typical 120/240V service need single-phase generators (typically up to 50 kW). Commercial and industrial sites with three-phase equipment require three-phase generators. Can’t mix and match—you need what your facility’s electrical service demands.

Standby vs. Prime vs. Continuous Ratings

Manufacturers rate generators three ways:

Standby rating: Maximum power for emergency use, limited hours per year (typically <500 hours annually). Use this for backup applications.

Prime rating: Can run unlimited hours with variable load, but not at 100% capacity continuously. Typical for primary power in off-grid sites with varying demand.

Continuous rating: Can run 24/7 at 100% load. Required for baseload power generation or data centers with no load variation.

Match the rating to your application. A hospital emergency generator needs standby rating. A remote construction site needs prime rating. Don’t pay for continuous rating if you don’t need it—it costs 15-25% more.

Step 4: Verify with Professional Load Analysis

You’ve done the math, selected a size, and you’re ready to buy. Not so fast. For anything over 50 kW or mission-critical applications, get a professional load analysis.

What Professionals Catch That You Might Miss

A qualified electrical engineer or generator consultant will:

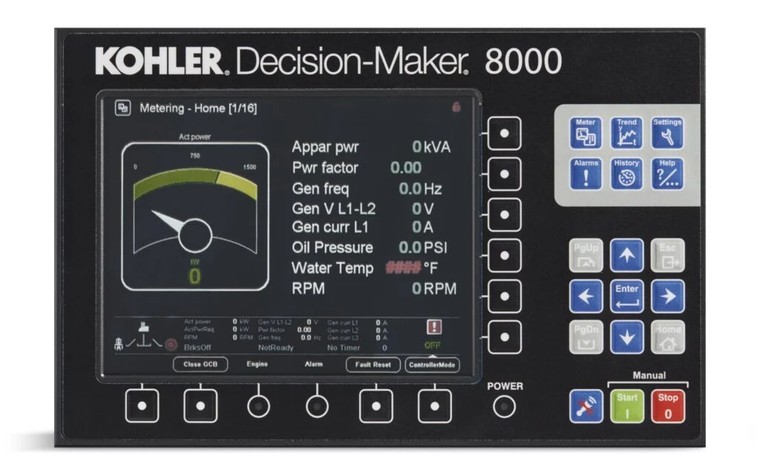

Account for power factor: Your calculated watts (W) need conversion to apparent power (kVA) based on your equipment’s power factor. Most facilities run 0.8-0.9 power factor, meaning your 75 kW load actually requires 83-94 kVA. Generators are often rated in kVA, not kW.

Check harmonic distortion: Computers, VFDs, and other electronic loads create harmonics that can require generator oversizing by 10-30%. Cummins diesel generators with advanced alternators handle harmonics better, but you still need to account for them.

Verify altitude and temperature derating: Remember, generators lose 3-4% power for every 1,000 feet above sea level and another 1% per 10°F above 77°F. Operating at 5,000 feet in 95°F weather? Your 100 kW generator effectively becomes an 80 kW unit.

Model transient response: When large loads start, voltage dips briefly. Sensitive equipment (medical devices, servers, automation) may trip offline if voltage sags below 80-85%. Engineers can model this and recommend appropriate alternator sizing or voltage regulation upgrades.

Load Bank Testing

After installation, insist on load bank testing. A load bank simulates your full electrical load, verifying the generator can actually deliver rated power without excessive voltage drop or frequency deviation. Tesla Power and reputable installers include this in their commissioning process. It’s your proof the system works before you actually need it in an emergency.

Load bank testing also conditions a new generator, seating piston rings and breaking in the engine properly. Skip this, and your first real emergency becomes your break-in period—not ideal.

Common Sizing Mistakes That Cost Thousands

Let me save you from the errors I’ve seen facility managers make repeatedly:

Mistake #1: Using nameplate ratings for motors without checking actual draw. That 10 HP motor isn’t necessarily drawing 10 HP continuously. Measure actual amperage with a clamp meter or use conservative estimates. Over-estimating every load by 20% “to be safe” means buying a generator 50-75% larger than needed.

Mistake #2: Forgetting about future expansion. If you’re planning to add equipment in the next 3-5 years, factor that into your sizing now. Adding a second generator later costs far more than buying the right size initially.

Mistake #3: Ignoring load shedding options. Not everything needs to run during an outage. Can you shed your office HVAC but keep the server room climate control? Drop non-essential lighting? Load shedding might let you size down by 20-30%.

Mistake #4: Buying residential-grade units for commercial applications. That 22 kW home standby generator won’t cut it for your 50-employee office. Commercial diesel generators are built for longer runtime, more frequent starts, and harsher environments. Spending 40% more upfront saves you from replacing a failed unit in 3 years.

Mistake #5: Overlooking fuel capacity vs. runtime. You sized the generator perfectly, but the 50-gallon fuel tank only gives you 8 hours of runtime. Your facility needs 48 hours of autonomy? You need a 300-400 gallon tank or bulk fuel delivery contracts. Tank sizing is part of system sizing.

Frequently Asked Questions

What’s the difference between kW and kVA ratings on generators?

kW (kilowatts) measures real power—the actual work being done. kVA (kilovolt-amperes) measures apparent power—the total power flowing through the system. The difference is power factor, typically 0.8-0.9 for most facilities. A 100 kW generator at 0.8 power factor actually delivers 125 kVA. Some manufacturers rate in kW, others in kVA. Always clarify which rating you’re looking at and confirm it matches your facility’s power factor.

Can I parallel two smaller generators instead of buying one large unit?

Absolutely, and it’s often smarter for redundancy. Two 75 kW generators in parallel give you 150 kW capacity with N+1 redundancy—if one fails, the other keeps critical loads running. Paralleling requires synchronization controls (adds $8,000-$15,000 to system cost) and both generators must be identical or specifically designed for paralleling. Cummins generators and Tesla Power units often come with paralleling capability built in. The fuel efficiency and redundancy benefits usually justify the added complexity for facilities over 100 kW.

How do I size a generator for a home versus a commercial building?

Homes typically have simpler loads (HVAC, appliances, lighting) with predictable surge patterns. You can use simplified calculators and often get away with a single-phase 20-30 kW unit for a large home. Commercial buildings have complex loads: elevators, three-phase motors, data centers, specialized equipment. You need detailed load calculations, professional engineering, and usually three-phase generators starting at 50 kW. Don’t apply residential sizing shortcuts to commercial applications—the equipment and stakes are entirely different.

What happens if I undersize my generator by 20-30%?

Depends on your load type. If you undersize by 20% but your actual runtime loads average 60% of calculated maximum, you might be fine—you’ve accidentally right-sized through underestimation. But if you actually run at calculated capacity, an undersized generator will either overload and shut down (best case), or run continuously above rated capacity, overheating and destroying itself in months instead of decades (worst case). Voltage and frequency instability will also damage sensitive equipment. Undersizing is a false economy that costs far more in the long run.

Should I choose diesel or natural gas for my generator?

For standby applications, diesel generators win: better fuel storage stability (diesel lasts 12-24 months with treatment vs. natural gas requiring utility connection), higher power density (smaller physical size for same output), and more reliable cold starts. Natural gas makes sense for prime power where you’re running thousands of hours annually and fuel cost becomes the dominant factor, or where local regulations restrict diesel. Diesel generator maintenance costs are slightly higher, but the reliability advantage for emergency backup power usually tips the scale toward diesel for most commercial applications.