Have you ever wondered what keeps hospitals running during power outages, or how remote construction sites maintain operations without grid access? The answer often lies in a robust piece of equipment that’s been powering critical operations for decades—the diesel generator. But what exactly is this machine, and how does it transform fuel into reliable electricity?

If you’re considering backup power solutions for your business or home, understanding diesel generators isn’t just helpful—it’s essential. This guide breaks down everything you need to know about diesel generators in plain language.

Understanding the Basics: What Is a Diesel Generator?

A diesel generator is a combination of a diesel engine and an electric generator (alternator) that converts mechanical energy into electrical power. Unlike gasoline-powered generators, diesel generators use compression ignition rather than spark plugs, making them more fuel-efficient and durable for long-term use.

Think of it as a self-contained power plant that can operate independently from the electrical grid. These units range from small portable diesel generators producing a few kilowatts to massive industrial generators capable of powering entire facilities with several megawatts of capacity.

Key Components Every Diesel Generator Set Needs

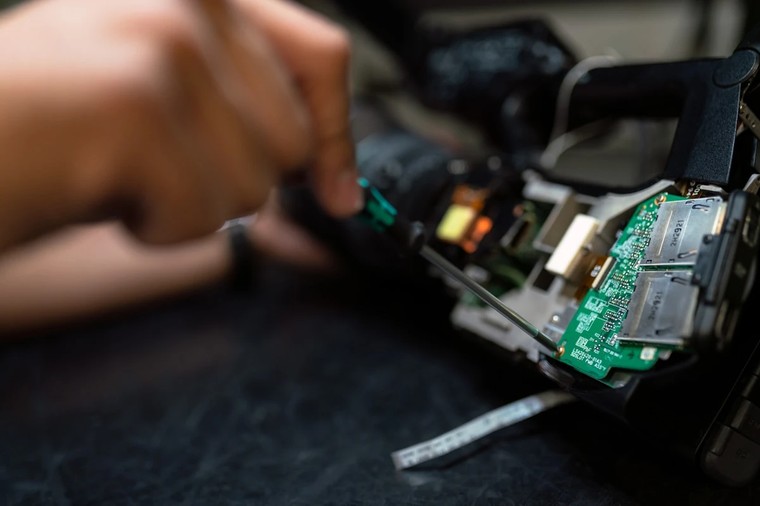

Every diesel generator set (commonly called a genset) consists of several essential components working in harmony:

- Diesel Engine: The heart of the system that burns diesel fuel to create mechanical energy

- Alternator: Converts rotational mechanical energy into electrical energy through electromagnetic induction

- Fuel System: Delivers clean diesel to the engine at proper pressure and volume

- Voltage Regulator: Maintains consistent voltage output regardless of load changes

- Cooling System: Prevents overheating through radiators and coolant circulation

- Exhaust System: Safely channels combustion gases and reduces noise

- Control Panel: Where you monitor performance and adjust settings

Companies like Tesla Power engineer these components to work seamlessly together, ensuring maximum reliability when you need power most.

How Does a Diesel Generator Work? The Four-Stroke Process

Understanding the operational process helps you appreciate why diesel generators remain the gold standard for reliable backup power systems. The process involves four distinct stages:

Stage 1: Air Intake and Compression

The diesel engine draws fresh air into its cylinders through intake valves. Unlike gasoline engines, diesel engines don’t mix fuel with incoming air initially. A piston compresses this air to roughly 1/20th of its original volume, generating intense heat—temperatures reaching between 500-700°C (932-1292°F).

Stage 2: Fuel Injection and Ignition

At peak compression, the fuel injection system sprays a fine mist of diesel fuel directly into the superheated compressed air. The extreme temperature causes spontaneous ignition—this is called compression ignition. No spark plug needed!

This controlled explosion forces the piston downward with tremendous force, creating the mechanical energy that powers the generator. The timing must be incredibly precise, typically controlled by advanced computer systems in modern generators.

Stage 3: Power Stroke and Energy Conversion

As fuel ignites and expands rapidly, it drives the piston downward in the power stroke. This linear motion transfers to a crankshaft, converting it into rotational motion—similar to how your legs pushing bicycle pedals creates wheel rotation.

The engine’s crankshaft connects directly to the alternator’s rotor—a shaft with powerful electromagnets. As the rotor spins at high speed, it creates a constantly changing magnetic field. According to Faraday’s Law of Electromagnetic Induction, this changing field induces electrical current in the stator’s copper wire coils.

Stage 4: Exhaust and Cycle Repetition

Exhaust valves open and the piston moves upward, pushing out spent combustion gases. Modern emission control systems filter harmful pollutants before they reach the atmosphere. As the piston reaches the top again, fresh air enters, and the entire cycle repeats.

Tesla Power generators incorporate advanced automatic voltage regulators (AVR) that respond within milliseconds to load changes, protecting sensitive electronics from voltage fluctuations.

Types of Diesel Generators: Which One Do You Need?

Not all diesel generators serve the same purpose. Understanding the different types helps you select the right power generation equipment for your needs.

Standby Generators

Standby generators are permanently installed units designed to provide emergency backup power during grid outages. They connect directly to your building’s electrical system through a transfer switch that automatically detects power loss and starts the generator within seconds. Common in hospitals, data centers, and commercial buildings.

Prime Power Generators

Prime power generators operate as the primary power source in locations without grid access. Construction sites, mining operations, and remote communities often rely on these units designed for unlimited hours of operation per year at 70-80% capacity.

Continuous Power Generators

For 24/7 non-stop power, continuous power generators provide maximum durability. These heavy-duty units power industrial facilities, large-scale farming operations, and island communities completely off-grid at 100% capacity indefinitely.

Portable Diesel Generators

Portable diesel generators offer flexibility for temporary power needs. These smaller units (typically 5-15 kW) are popular for outdoor events, camping, and emergency home backup. They’re the practical choice for homeowners who want affordable backup power without permanent installation.

Why Choose Diesel Over Gasoline? The Key Advantages

The fuel choice for your generator significantly impacts performance, operating costs, and maintenance. Diesel offers several distinct advantages:

Superior Fuel Efficiency and Energy Density

Diesel fuel contains approximately 10-15% more energy per gallon than gasoline, meaning diesel generators produce more power from less fuel. For emergency generators that may need to run for days during extended outages, this efficiency becomes critical. A diesel generator can often run 8-12 hours on a single tank, while a comparable gasoline unit might need refueling every 4-6 hours.

Exceptional Durability and Longevity

Diesel engines are built more robustly because they must withstand higher compression ratios. With proper maintenance, a quality diesel generator set can operate for 15,000-30,000 hours before requiring major overhaul—that’s 2-4 years of continuous operation! Manufacturers like Tesla Power design their diesel generators with industrial-grade components that maximize lifespan even under harsh conditions.

Better Safety and Fuel Stability

Diesel fuel is significantly less flammable than gasoline, reducing fire risk during storage and operation. Additionally, properly treated diesel can be stored for 6-12 months without degradation, while gasoline breaks down within 3-6 months. For standby generator applications where the unit may sit idle for months, this storage stability is invaluable.

Lower Maintenance Requirements

Diesel generators operate at lower RPMs (1,500-1,800) compared to gasoline generators (3,000-3,600). This slower operation creates less engine wear and extends maintenance intervals. The compression ignition system eliminates spark plugs and ignition coils that frequently need replacement in gasoline engines.

Factors That Affect Diesel Generator Performance

Even the best-designed generator won’t perform optimally if certain factors aren’t properly managed:

Load Management Matters

Running a diesel generator consistently below 30% of rated capacity can cause “wet stacking”—unburned fuel accumulating in the exhaust system. Conversely, operating above 80% causes excessive wear. The sweet spot is 60-80% of rated capacity for optimal efficiency and longevity.

Environmental Conditions Impact Output

At higher altitudes, power output reduces by approximately 3-4% for every 1,000 feet above sea level due to thinner air. Extreme temperatures also affect performance—cold weather thickens diesel fuel, while hot weather reduces cooling efficiency.

Fuel Quality Is Critical

Contaminated fuel is the leading cause of diesel generator failures. Water, dirt, algae growth, and chemical degradation can all cause system damage. Tesla Power generators incorporate advanced fuel filtration systems with water separators that protect against contamination.

Regular Maintenance Is Non-Negotiable

Critical maintenance tasks include oil and filter changes every 250-500 hours, coolant system checks every 1-2 years, air filter replacement quarterly, fuel filter replacement every 400-500 hours, and battery testing every 3-5 years.

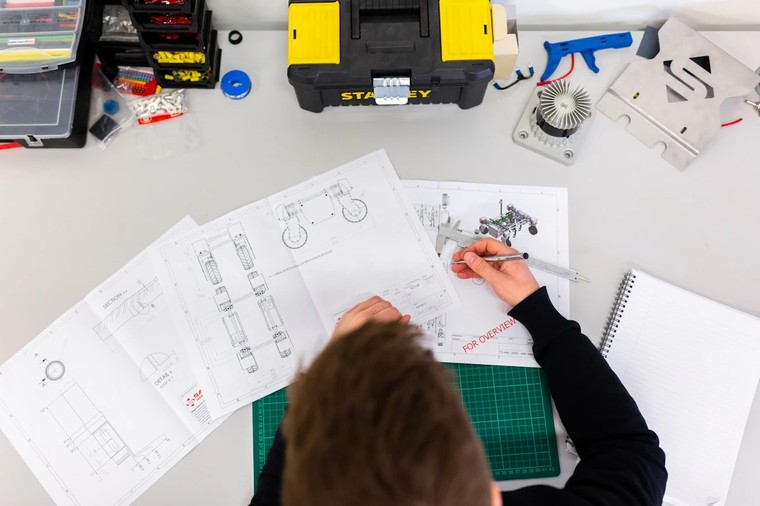

Essential Tools and Technologies for Optimization

Modern diesel generator sets incorporate sophisticated technologies:

Automatic Transfer Switches (ATS): Monitors grid power and automatically starts your generator within 10-30 seconds of power loss, with no manual intervention needed.

Remote Monitoring Systems: Track performance from anywhere via smartphone, receiving real-time alerts about operating parameters and maintenance needs. Tesla Power integrates cloud-based monitoring for complete visibility.

Load Bank Testing Equipment: Simulates real electrical loads to verify capacity and prevent wet stacking through quarterly testing at 75-80% capacity.

Fuel Polishing Systems: Continuously circulates stored fuel through filtration, extending storage life from months to years.

Real-World Applications Across Industries

Healthcare Facilities

Hospitals cannot tolerate power interruptions. Standby generators sized to power entire facilities activate within seconds of grid failure, ensuring patient care continues. Most healthcare codes require 96-hour fuel storage minimum.

Data Centers and Telecommunications

Digital infrastructure demands absolute power reliability. Large data centers deploy multiple paralleled industrial generators with N+1 redundancy. Telecommunications towers in remote locations often run entirely on diesel power.

Construction and Manufacturing

Remote work sites lack grid access, making generators the sole power source. The durability and fuel efficiency of diesel generator sets make them economically superior for demanding applications requiring long-term reliability.

Agriculture and Food Processing

Power outages can destroy crops or kill livestock worth hundreds of thousands of dollars. Tesla Power has supplied numerous agricultural clients with reliable backup power that protects their investments and ensures business continuity.

How to Choose the Right Diesel Generator

Selecting appropriate power generation equipment requires careful analysis:

- Calculate Power Requirements: List all equipment you need to power, including startup surge requirements. Add 20-25% buffer for future expansion.

- Determine Runtime Needs: How long must your generator operate during typical outages? Your fuel storage should support at least 24-48 hours of continuous operation.

- Assess Installation Constraints: Consider physical space, ventilation requirements, noise restrictions, and environmental regulations.

- Evaluate Total Cost of Ownership: Factor in installation costs, ongoing fuel expenses, maintenance costs over 20-30 years, and potential repair costs.

- Check Manufacturer Support: Investigate reputation, parts availability, technical support responsiveness, warranty coverage, and local dealer network density.

Tesla Power provides transparent total cost of ownership calculations to help you make informed decisions based on long-term value rather than just upfront cost.

Environmental Considerations and Modern Solutions

Environmental responsibility matters to both regulators and conscientious businesses. Modern diesel generators incorporate technologies that significantly reduce environmental impact:

Tier 4 Final diesel engines produce 90% fewer emissions than engines from two decades ago through diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR).

Many diesel generators can operate on biodiesel blends (B5, B10, B20) made from renewable sources, reducing greenhouse gas emissions by 50-85%. Tesla Power approves biodiesel blends up to B20 without modifications.

Hybrid approaches combining solar panels with diesel generators maintain reliability while dramatically cutting fuel costs and environmental impact.

Frequently Asked Questions

How long can a diesel generator run continuously without stopping?

Most modern diesel generators can run continuously for hundreds or even thousands of hours without stopping, provided they receive proper maintenance and fuel supply. Manufacturers typically recommend stopping for routine maintenance every 250-500 hours. Continuous-rated generators designed for 24/7 operation can theoretically run indefinitely with only scheduled maintenance downtime. For standby generators designed for occasional emergency use, running continuously for 3-5 days during extended outages presents no problems.

What size diesel generator do I need to power my home?

To determine the right size diesel generator for home use, calculate your essential power requirements during an outage. A typical home needs 7-12 kW to power critical systems (refrigerator, lights, heating/cooling, well pump), while whole-house coverage typically requires 15-20 kW for homes under 2,000 square feet, and 20-30 kW for larger homes with central air conditioning. Start by listing all essential appliances with their running wattage, add them together, then multiply by 1.25 to account for startup surges. Tesla Power offers free load calculation services to recommend optimal generator size.

How often should I run my diesel generator if it’s rarely used?

Diesel standby generators that sit idle should be exercised monthly to maintain reliability. Run the generator for 30-60 minutes at 50-75% load to circulate fluids, charge batteries, lubricate seals, and identify potential issues before emergencies. Many modern generators feature automatic exercise modes that handle this maintenance automatically. Additionally, schedule professional maintenance annually including oil changes, filter replacement, battery testing, and comprehensive inspection.

Are diesel generators safe to use indoors?

Never operate a diesel generator indoors or in enclosed spaces without proper industrial ventilation systems. Diesel exhaust contains carbon monoxide—an odorless, colorless gas that can cause death within minutes. Diesel generators must always be placed outdoors with exhaust directed away from buildings, windows, and air intakes. Minimum clearances are typically 3-5 feet from buildings for proper ventilation and service access.

How does diesel generator cost compare to other backup power options?

Diesel generator initial costs typically run $300-600 per kilowatt for residential units and $200-400 per kilowatt for commercial systems, plus installation expenses of $3,000-7,000. While 15-30% more expensive upfront than gasoline generators, total cost of ownership over 20-25 years favors diesel significantly due to superior fuel efficiency (30-50% better), longer lifespan (15,000-30,000 hours vs. 5,000-10,000 for gasoline), lower maintenance frequency, and higher resale value. Tesla Power offers financing options and total cost of ownership analysis to help customers understand long-term economics.