When your facility loses power, every minute counts. For industrial and commercial operations, a single power outage can mean lost production, spoiled inventory, disrupted services, and frustrated customers. Recent industry data shows that 54% of significant outages cost businesses over $100,000, with 20% exceeding $1 million in damages.

That’s where an industrial diesel generator becomes more than just backup equipment—it’s insurance for your bottom line. But with price tags ranging from tens of thousands to hundreds of thousands of dollars, the question isn’t whether you need backup power. It’s whether a diesel generator specifically justifies the investment compared to natural gas, propane, or other alternatives.

Let’s cut through the technical jargon and marketing claims to explore what actually makes industrial diesel generators worth considering for your facility.

Unmatched Power Reliability When It Matters Most

If there’s one reason diesel dominates industrial backup power, it’s this: diesel generators deliver rock-solid performance under the exact conditions that break other systems.

Fast Response to Sudden Load Changes

Here’s what happens when your manufacturing line suddenly demands power or a data center kicks on cooling equipment. Your generator needs to absorb that electrical surge without voltage sags that could damage sensitive equipment or trip safety systems. This is called transient response, and it’s where diesel engines truly shine.

Industry standards (ISO 8528-5) define performance classes for how generators handle load steps. Most industrial diesel generators are engineered to meet G3 class requirements, maintaining voltage within ±15% to +20% and frequency within ±7% to ±10% during load changes, with recovery times under 3-4 seconds. Compare that to natural gas engines, which typically respond slower due to fuel delivery characteristics and may require oversizing or load sequencing to meet the same specifications.

Built for the Long Haul

Diesel engines are workhorses by design. The compression-ignition principle means fewer spark-related failures, and the robust construction needed to handle higher compression ratios translates to components that simply last longer under heavy use.

When manufacturers rate generators, they distinguish between standby duty (limited to roughly 200-500 hours per year) and prime power ratings (designed for unlimited operating hours). A properly specified diesel genset in prime rating can serve as your facility’s main power source indefinitely, not just emergency backup. That durability matters when you’re running extended outages or operating off-grid for seasonal facilities.

Power Quality for Sensitive Equipment

Modern facilities run on electronics—PLCs controlling production lines, servers managing operations, variable frequency drives powering HVAC systems. These systems need clean, stable power. Voltage dips, frequency swings, or harmonic distortion can cause nuisance trips, corrupted data, or equipment damage.

Diesel’s mechanical stability and predictable fuel combustion produce inherently cleaner power with tighter voltage and frequency control. This becomes critical in applications like hospitals where life-safety equipment can’t tolerate power quality issues, or data centers where even milliseconds of instability can cascade into service disruptions.

Efficiency That Pays Off Over Time

Your generator’s efficiency directly impacts your wallet. Every gallon of fuel burned shows up on your operating budget, and over a 10-15 year lifespan, fuel costs typically dwarf the initial purchase price.

Fuel Efficiency in Real Numbers

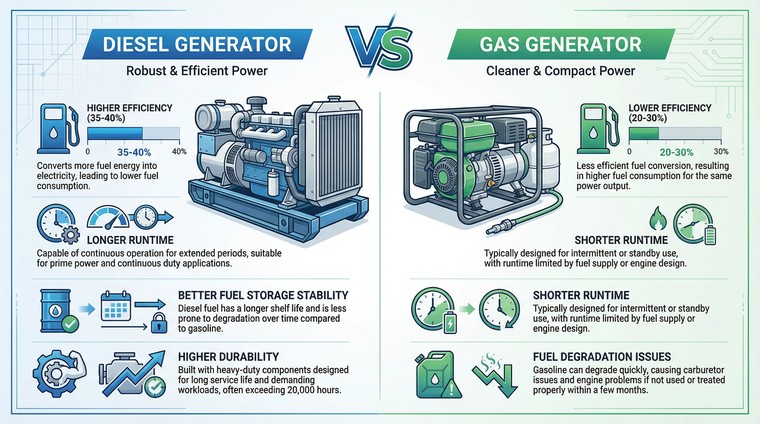

Diesel fuel packs more energy per gallon than gasoline or propane—about 130,000 BTU per gallon for diesel versus 115,000 for gasoline. But the real advantage comes from compression-ignition engines converting more of that energy into electrical power. While gasoline generators typically achieve 20-30% thermal efficiency, diesel generator efficiency commonly reaches 35-40% or higher at optimal loads.

What does that mean practically? A 100 kW commercial generator running at 75% load might consume around 6-7 gallons of diesel per hour, depending on the specific model and site conditions. Manufacturer specification sheets break down consumption rates at common load points—50%, 75%, 100%—letting you calculate operating costs based on your expected usage patterns and local fuel pricing.

For a facility that runs its standby generator for 50 hours annually during grid outages and testing, that efficiency difference might save you $500-1,000 per year compared to gasoline. Not dramatic. But for operations using generators in prime power mode for hundreds or thousands of hours? Those savings compound quickly, often recovering any upfront cost premium within a few years.

Fuel Stability and Storage

Here’s an often-overlooked advantage: diesel stores better than gasoline. Gasoline degrades in as little as 3-6 months without stabilizers, forming varnish that can gum up carburetors and fuel systems. Diesel remains stable for 6-12 months or longer with minimal treatment, and it’s less volatile, reducing fire risk in storage.

For emergency generators that might sit idle for months between uses, this reliability matters. You can’t afford to have your backup system fail to start when the grid goes down because stale fuel clogged the injectors.

The Real Cost Analysis: Beyond the Sticker Price

Let’s talk money, because that’s ultimately what “worth the investment” means. Yes, an industrial diesel generator costs more upfront than equivalent gasoline or propane units—often 20-40% more for the same power rating. But that’s only the beginning of the financial story.

Total Cost of Ownership

Smart buyers evaluate total cost of ownership (TCO) over the equipment’s expected lifespan, typically 15-25 years for well-maintained diesel gensets. TCO includes:

- Initial purchase and installation: $15,000-$50,000 for a 50-100 kW unit; $50,000-$200,000+ for larger industrial systems

- Fuel costs: Varies widely by usage; prime power applications may burn $10,000-$50,000+ annually

- Maintenance: Routine service runs $1,000-$5,000 annually depending on size and usage

- Repairs and parts: Budget 1-3% of initial cost annually for a properly maintained unit

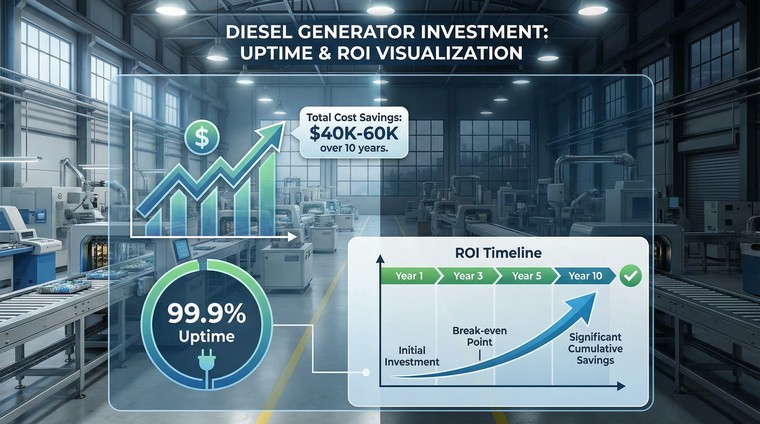

The efficiency advantage mentioned earlier becomes material here. If you’re running 500 hours per year at 100 kW output, a diesel unit consuming 7 gallons per hour at $4/gallon costs $14,000 annually in fuel. A less efficient gasoline unit might burn 9-10 gallons per hour, adding $4,000-$6,000 per year to your fuel bill. Over ten years, that’s $40,000-$60,000 in additional expense that could have paid for the diesel unit’s cost premium several times over.

The Downtime Cost Equation

Here’s where the ROI gets really interesting. Remember those outage statistics from the introduction? When you frame backup power not as an expense but as protection against catastrophic loss, the equation shifts dramatically.

Consider a modest manufacturing operation generating $500,000 in monthly revenue. A single 8-hour outage that shuts down production might cost:

- Lost production: $13,000-$20,000 (depending on margins and catch-up capacity)

- Spoiled materials or work-in-progress: $2,000-$10,000

- Overtime to recover schedule: $3,000-$5,000

- Customer penalties or expedited shipping: Variable, sometimes substantial

A $75,000 industrial diesel generator that prevents even one or two major outages over its lifespan has paid for itself. For critical facilities like hospitals, data centers, or food processing plants where outages literally endanger lives or trigger regulatory issues, the ROI is even more compelling.

Choosing Quality Pays

Not all generators are created equal. Reputable manufacturers like Tesla Power, Caterpillar, Cummins, and others offer industrial-grade units engineered for reliability and backed by extensive service networks. The $10,000 you might save buying an off-brand unit often costs you much more in premature failures, parts availability issues, and lower resale value.

When evaluating options from brands such as Tesla Power, compare warranty terms, local service availability, parts lead times, and documented MTBF (mean time between failures) specifications. A generator that runs when you need it is infinitely more valuable than one that saves money sitting broken in your equipment yard.

Real-World Applications: Who Benefits Most?

Theory is one thing. Let’s look at who’s actually relying on industrial diesel generators and why.

Manufacturing and Production Facilities

Manufacturing operations face a perfect storm of power vulnerability. Production lines with motors, robotics, and PLCs need stable power. Raw materials or semi-finished products may be temperature-sensitive or time-critical. Quality control systems require continuous monitoring.

A mid-sized automotive parts manufacturer might run a 250 kW diesel generator as their emergency generator, sized to keep critical production cells, material handling equipment, and climate control running during outages. The alternative—sending workers home, scrapping in-process materials, and missing delivery schedules—quickly justifies the investment.

Healthcare Facilities

Hospitals and surgical centers represent perhaps the most critical application. Life support equipment, operating rooms, imaging systems, refrigeration for medications and blood products—none of these can tolerate even brief interruptions.

Codes and regulations mandate backup power for healthcare facilities, and diesel generators dominate this space for good reason. A 500 kW to 2 MW diesel unit can provide continuous power for days or weeks if needed, with reliable starting and rock-solid voltage regulation that gaseous alternatives struggle to match in transient-heavy medical equipment loads.

Data Centers and Telecom

When your business is uptime, generator reliability becomes existential. Data centers and telecommunications facilities need backup systems that start reliably, accept heavy transient loads from cooling systems and servers, and run for extended periods during grid emergencies.

The industry standard architecture pairs UPS systems (handling millisecond-scale transitions) with diesel gensets (sustaining power for hours or days). Even small edge data centers typically install 100-500 kW units, while hyperscale facilities deploy multiple megawatt-class generators in parallel configurations.

Agriculture and Remote Operations

Farms and remote industrial sites face unique challenges. Grid power may be unreliable or unavailable. Seasonal operations might need prime power for processing equipment during harvest. Livestock facilities require 24/7 ventilation and climate control.

A portable diesel generator or semi-permanent installation provides the flexibility these operations need. Fuel can be delivered in bulk and stored safely on-site. The units run reliably in temperature extremes and dusty conditions that would choke gasoline engines or complicate natural gas infrastructure.

Maintenance Reality Check: What to Expect

Let’s be honest—diesel generator maintenance requires commitment. But it’s neither mysterious nor prohibitively expensive if you approach it systematically.

Routine Service Intervals

Most diesel gensets follow predictable maintenance schedules tied to operating hours:

- Daily/weekly (if running): Visual inspections, fluid level checks, leak monitoring

- Monthly: Exercise run (typically 30 minutes under load to prevent wet stacking)

- Every 100-250 hours: Oil and filter changes, fuel filter replacement, coolant checks

- Annually or 500 hours: More extensive service including air filter, spark arrestor cleaning, battery testing, load bank testing

- Every 2-3 years: Major service including valve adjustments, injector inspection, cooling system service

For a typical standby generator running 50-100 hours annually including testing, you’re looking at one or two service visits per year. Contrast that with critical equipment running thousands of hours, which demands more frequent attention.

Common Maintenance Tasks

The good news? Diesel maintenance is straightforward. You’re changing oil and filters, checking belts and hoses, testing batteries, maintaining fuel quality—basic mechanical work that any qualified technician or in-house maintenance team can handle. Parts are standardized and widely available for major brands.

The bad news? Neglect catches up quickly. Skip exercise runs and you risk fuel system issues or cylinder glazing. Ignore cooling system maintenance and you’ll face expensive overhaul bills. Let batteries age past their service life and your generator won’t start when you need it.

Budget Planning

For budgeting purposes, expect to spend roughly:

- Routine maintenance: $800-$2,000 annually for a 100 kW unit (more for larger systems or higher usage)

- Parts replacement: $500-$1,500 annually averaged over time (batteries every 3-5 years, belts, filters, fluids)

- Emergency repairs: Budget 1-2% of replacement cost annually as a contingency

A well-maintained industrial diesel generator can deliver 20,000-30,000 hours of service before requiring major overhaul. That’s 20-30 years for a lightly-used standby unit, or 10-15 years for prime power applications. Factor that longevity into your TCO calculations.

Making the Right Choice for Your Facility

You’re convinced diesel makes sense. Now what? Proper selection means matching the generator to your actual needs—not over-buying capacity you’ll never use or under-sizing and risking failures.

Calculate Your Load

Start with a comprehensive electrical load assessment. List every piece of equipment you need to power during an outage:

- Running loads: Continuous power draw (lights, computers, HVAC, production equipment)

- Starting loads: Brief surge current when motors and compressors start (often 3-6x running current)

- Future expansion: Room for growth over the next 5-10 years

Add a safety margin of 20-25% for unexpected loads or load diversity. This prevents running at 100% capacity continuously, which reduces service life and limits your ability to handle transients.

Understand Ratings

Manufacturers publish multiple power ratings. Make sure you’re comparing correctly:

- Standby (ESP): Maximum power for limited hours per year (typically ~200-500 hours). This is emergency-only operation.

- Prime (PRP): Unlimited hours with variable load. Suitable for facilities where the generator provides primary power with periodic load variation.

- Continuous (COP): Unlimited hours at constant load. For applications requiring 24/7 operation at fixed output.

Buying a 100 kW standby-rated unit when you need prime power means you’re actually getting roughly 80-90 kW of usable capacity for extended operation. ISO 8528-1 defines these categories—make sure your generator manufacturer clearly specifies which rating applies.

Consider Site Factors

Your environment affects performance:

- Altitude: Deduct 3-4% of power output for every 1,000 feet above sea level

- Temperature: High ambient temps reduce available power; very low temps may require block heaters

- Fuel storage: How much on-site fuel capacity do you need? Calculate based on expected outage duration and consumption rate

- Noise regulations: Check local codes; you may need sound-attenuated enclosures

- Exhaust and ventilation: Adequate airflow prevents overheating; plan exhaust routing carefully

Don’t Compromise on Automatic Transfer Switches

Your generator is only as good as the transfer switch that connects it to your electrical system. An automatic transfer switch (ATS) monitors utility power, starts the generator when it fails, transfers the load, then reverses the process when utility power returns.

Invest in a quality ATS rated for your load with appropriate service entrance ratings. Cheap out here and you’ll face nuisance trips, failed transfers, or worse—damage to connected equipment from poor switching quality.

The Bottom Line: When Diesel Makes Sense

So, what makes an industrial diesel generator worth the investment? It comes down to your specific situation and priorities.

Diesel delivers unmatched reliability for critical applications where power quality, transient response, and durability matter. The higher upfront cost is offset by superior fuel efficiency, longer service life, and lower operating costs over time. For facilities where power outages carry substantial financial or safety consequences—manufacturing plants, hospitals, data centers, and similar operations—the ROI is straightforward and compelling.

That said, diesel isn’t always the answer. Smaller facilities with minimal power needs, locations with strict emissions regulations, or applications requiring only occasional backup might find natural gas or propane more cost-effective. The key is honest assessment of your requirements, total cost analysis over the equipment’s lifespan, and selection of quality equipment from reputable manufacturers like Tesla Power and others who stand behind their products.

If your operation depends on uninterrupted power and you’re willing to commit to proper maintenance, a well-chosen diesel generator will likely prove one of the smartest infrastructure investments you make. It’s not cheap insurance—but when the lights stay on and your business keeps running while competitors sit in the dark, you’ll understand exactly what you paid for.

Frequently Asked Questions

How long can a diesel generator run continuously?

It depends on the rating. A standby generator is typically limited to 200-500 hours per year and shouldn’t run continuously for more than a few days. However, a prime-rated or continuous-rated industrial diesel generator can run indefinitely with proper maintenance and adequate fuel supply. Many industrial facilities operate diesel generators 24/7 for months or years in prime power applications. The key is selecting the correct rating for your intended use and following the manufacturer’s maintenance schedule. Continuous operation does accelerate wear, so budget accordingly for more frequent service intervals.

What’s the difference between diesel and natural gas generators for industrial use?

The main differences come down to fuel characteristics, engine design, and performance. Diesel generators typically offer better transient response (handling sudden load changes), higher fuel efficiency, and more predictable fuel supply since diesel is stored on-site. Natural gas generators connect to utility gas lines (eliminating fuel storage) but may experience supply disruptions during emergencies. Natural gas burns cleaner with lower emissions, making it preferable in areas with strict air quality regulations. Diesel engines generally last longer and tolerate heavier loads better. For most industrial applications requiring maximum reliability and power quality, diesel remains the default choice.

How much does it cost to maintain an industrial diesel generator?

For a typical 100 kW diesel genset, expect annual maintenance costs of $1,500-$3,500 depending on usage and service requirements. This includes routine oil changes, filter replacements, fluid checks, battery maintenance, and annual load bank testing. Larger units or those running more hours will cost proportionally more. Budget an additional 1-2% of the generator’s replacement cost annually for unexpected repairs and parts replacement. Over a 15-20 year lifespan, maintenance will likely total 30-50% of the original purchase price—but that’s still far less than the cost of a single major outage for most industrial operations.

Can diesel generators handle motor starting loads?

Yes, and this is actually one of diesel’s key advantages. Diesel generators excel at handling the high inrush currents when motors, compressors, and other inductive loads start. The engine’s mechanical characteristics and fuel delivery system respond quickly to sudden load increases, maintaining voltage and frequency within acceptable limits. When sizing a commercial generator for facilities with significant motor loads, work with a qualified engineer to calculate starting kVA requirements. You may need to oversize the alternator or sequence large motor starts to prevent excessive voltage dips, but diesel’s transient performance makes it well-suited for these challenging applications.

How do I choose between standby and prime power ratings?

Choose based on your expected annual operating hours and load pattern. Select a standby rating if your generator will only run during occasional grid outages and monthly testing—typically under 200-500 hours per year total. Choose a prime rating if you expect regular operation with variable loads or if you might use the generator as your primary power source during peak demand periods. Prime-rated generators cost more but are engineered for unlimited operating hours. Using a standby-rated unit in continuous service will dramatically shorten its life and void warranties. When in doubt, consult with your generator manufacturer or a qualified power systems engineer to match the rating to your specific duty cycle.