When you’re investing in backup power or prime power generation for your facility, the manufacturer behind your diesel generator matters just as much as the nameplate on the engine. You’ve probably heard of Volvo—synonymous with Swedish engineering, durability, and reliability. But what actually sets Volvo diesel generator manufacturers apart from competitors in the crowded industrial power market?

Let me walk you through the key differentiators that make Volvo-powered generator sets a compelling choice, drawing on real-world specifications, engineering philosophy, and the unique value proposition these manufacturers bring to the table.

Understanding the Volvo Penta Foundation

Before we dive into what makes the manufacturers different, it’s important to understand the engine at the heart of these systems: Volvo Penta. Unlike some engine brands that span consumer and industrial markets with varying quality tiers, Volvo Penta has been laser-focused on industrial and marine applications since 1907.

Purpose-Built Industrial Engines

Volvo Penta’s power generation engine lineup—particularly the TAD and TWD series—are purpose-designed for genset duty. Take the TAD1641GE as an example: this in-line six-cylinder, 16.12-liter engine delivers 430 kW at 1500 rpm (prime power) and can handle continuous duty cycles that would stress engines originally designed for automotive or light-duty use.

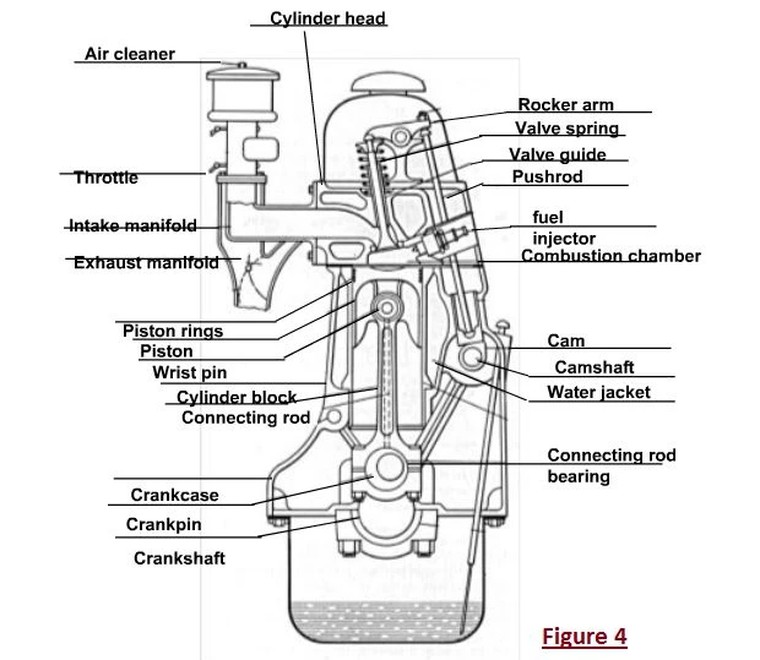

What does “purpose-built” really mean? It means features like:

- Wet cylinder liners that can be replaced during overhaul without machining the block

- Piston cooling via oil jets to manage sustained high loads

- Replaceable valve guides and seats for extended service life

- Four valves per cylinder with overhead camshaft for efficient breathing

These aren’t marketing buzzwords—they’re tangible design choices that translate into 25,000+ hour service intervals when properly maintained, according to industry data.

Adherence to International Standards (ISO 8528 & ISO 3046)

Here’s where many generator manufacturers start to diverge. Tesla Power and other reputable Volvo diesel generator manufacturers strictly apply ISO 8528 and ISO 3046 standards to their rating and performance claims.

What Are These Standards?

ISO 8528 defines:

- Prime Power (PRP): Maximum continuous power available with variable load, unlimited hours per year

- Standby Power (ESP): Maximum power for emergency use, limited to 200 hours per year with no constant loads

ISO 3046 specifies how to measure and declare engine performance under standardized conditions (ambient temperature, altitude, etc.).

Why Does This Matter to You?

Because not all “kilowatts” are created equal. Some manufacturers quote peak power without defining duty cycle or environmental corrections. When a Volvo diesel generator manufacturer states “430 kW prime,” that’s a contractual guarantee backed by testing protocols—you can run that genset 24/7/365 at variable loads up to 430 kW.

Compare that to manufacturers who blur the lines between ratings or quote “maximum” figures without context. The difference shows up in warranty claims and unexpected downtime when your generator can’t deliver promised power during a heat wave or at altitude.

Advanced Electronic Management Systems

Walk into a facility powered by a modern Volvo diesel generator, and you’ll likely encounter the EMS 2 (Engine Management System) with CAN J1939 interface. This isn’t just a digital gauge cluster—it’s a comprehensive diagnostics and control platform.

Real-Time Monitoring and Diagnostics

The EMS 2 system provides:

- Continuous parameter monitoring: Coolant temperature, oil pressure, fuel rate, engine speed, power output

- Predictive alarms: Warning thresholds before critical shutdowns

- Fault code logging: Timestamped diagnostic trouble codes (DTCs) for rapid troubleshooting

- Remote interface capability: Via DCU (Display Control Unit) or CIU (Control Interface Unit)

Tesla Power integrates these systems seamlessly into their generator packages, often adding custom alarm relay panels or remote monitoring gateways that let facility managers check genset status from anywhere.

The Uptime Advantage

According to maintenance data from power generation specialists, facilities using generators with integrated EMS 2 and proactive diagnostics report:

- 15-20% reduction in unplanned maintenance events

- Faster MTTR (mean time to repair) because technicians arrive with fault codes already pulled

- Extended component life through early detection of trends (like rising coolant temperature indicating a clogged radiator)

Fuel Efficiency Across Load Bands

Let’s talk about something that directly impacts your bottom line: fuel consumption. Volvo Penta engines publish detailed specific fuel consumption (SFC) curves in grams per kilowatt-hour (g/kWh) across load bands.

Real Numbers from a Real Engine

For the TAD1641GE at 1500 rpm (prime rating):

- 25% load: ~210 g/kWh

- 50% load: ~201 g/kWh

- 75% load: ~198 g/kWh

- 100% load: ~202 g/kWh

At 1800 rpm (prime rating):

- 50% load: ~201 g/kWh

- 100% load: ~200 g/kWh

Notice the “sweet spot” around 75% load? That’s where combustion efficiency peaks. Volvo diesel generator manufacturers like Tesla Power help customers size gensets to operate in this range during typical load profiles, minimizing fuel cost without sacrificing transient response.

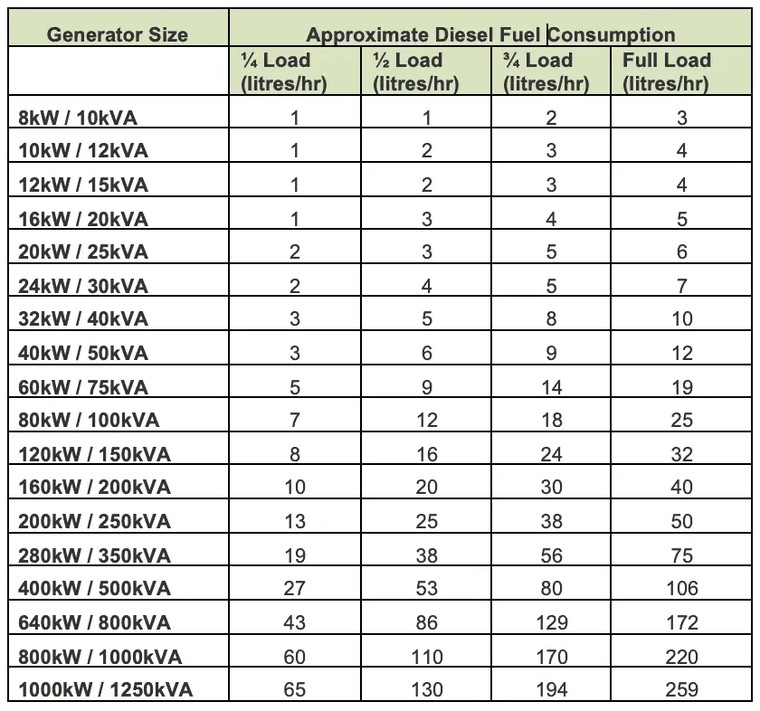

Converting to Liters Per Hour

To translate g/kWh into L/h (what you actually pump into the tank):

Fuel consumption (L/h) = [Power (kW) × SFC (g/kWh) × Alternator efficiency factor] / [Diesel density (~835 g/L) × 1000]

For a 430 kW genset at 75% load (~322 kW), running at ~198 g/kWh:

Fuel consumption ≈ [322 × 198 × 1.05] / (835 × 1000) ≈ 80 L/h

Over a year of continuous operation (8,760 hours), that’s ~700,800 liters. A 5% improvement in SFC (achievable through proper sizing and maintenance) saves 35,000+ liters annually—a substantial TCO reduction.

Emissions Compliance and Environmental Responsibility

Power generation is increasingly regulated. Volvo diesel generator manufacturers don’t just meet minimum standards—they often exceed them.

Current Compliance Landscape

The TAD1641GE, for example, complies with:

- EU Stage 2 emissions for stationary engines

- TA-Luft standards (German Clean Air Act) at −50% below thresholds

These aren’t legacy engines grandfathered under old rules. Volvo Penta continuously updates its lineup to meet evolving regulations in North America (EPA Tier standards), Europe (EU Stage directives), and other markets.

Why Stricter Standards Benefit You

Beyond regulatory compliance, lower emissions often correlate with:

- Cleaner combustion = less carbon buildup = longer intervals between top-end overhauls

- Better fuel atomization = improved fuel economy

- Reduced particulate matter = less filter clogging in enclosed installations

When Tesla Power quotes you a Volvo-powered genset, they’re delivering a system engineered for both today’s regulations and likely future tightening—protecting your investment from premature obsolescence.

Global Service Network and Parts Availability

Here’s a differentiator that’s easy to overlook until you need it: aftermarket support.

The Volvo Penta Advantage

Volvo Penta maintains:

- Authorized service centers in over 130 countries

- Parts distribution hubs with same-day or next-day shipping in major markets

- Technical support hotlines staffed by factory-trained engineers

- Online parts catalogs with exploded diagrams and OEM part numbers

Volvo diesel generator manufacturers like Tesla Power leverage this ecosystem to provide:

- Turnkey maintenance contracts backed by OEM parts

- Emergency parts stocking agreements for critical operations

- Field service teams trained directly by Volvo Penta

Contrast with Lesser-Known Brands

I’ve seen facilities struggle with generators powered by obscure or rebadged engines where:

- Parts require international freight with weeks of lead time

- Service manuals are poorly translated or incomplete

- Local technicians refuse to work on unfamiliar platforms

With Volvo, you’re buying into a mature support infrastructure that treats generator downtime as unacceptable.

Durability Features: Designed for Overhaul, Not Disposal

Modern environmental consciousness demands we design for longevity and repair, not planned obsolescence. Volvo Penta engines embody this philosophy.

Serviceability by Design

Key durability elements include:

Wet Cylinder Liners: When bore wear exceeds tolerance after 20,000+ hours, liners can be pulled and replaced without scrapping the block. The block itself can serve multiple overhaul cycles.

Replaceable Valve Train Components: Valve guides, seats, and springs are wear items designed for replacement during top-end overhauls. No need for exotic machining or welding repairs.

Accessible Service Points: Oil filters, fuel filters, coolant drains, and inspection covers are positioned for tool access. The TAD series features a side-mounted fuel filter housing and top-mounted oil filter for easy servicing even in tight genset enclosures.

Robust Main Bearings: Seven-main-bearing crankshaft with tri-metal bearing inserts distributes loads evenly, extending bearing life and reducing vibration.

The Rebuild Economics

A properly maintained Volvo Penta engine can undergo:

- Minor overhaul at ~15,000-20,000 hours (rings, bearings, liners, valves): ~40-50% of new engine cost

- Major overhaul at ~30,000-40,000 hours (adding crankshaft regrind/replacement): ~60-70% of new engine cost

Compare to disposable engine designs where the cost and complexity of overhaul approaches replacement. Volvo diesel generator manufacturers offer rebuild programs that extend asset life to 50,000+ hours—decades of service for critical infrastructure.

Modular Integration and Customization

Tesla Power and other leading manufacturers don’t just bolt a Volvo engine to a generic alternator and call it done. They engineer integrated power systems.

Matched Components

A quality Volvo diesel generator package includes:

- Alternator selection: Matched to engine torque curve and governing response (typically Stamford, Leroy-Somer, or Mecc Alte for Volvo packages)

- Cooling system design: Radiator sized for worst-case ambient conditions with margin for fan belt degradation

- Acoustic enclosures: Engineered to specific dB(A) targets without compromising airflow (common targets: 65-75 dB(A) at 7 meters)

- Fuel system integration: Day tank sizing, fuel polishing provisions, leak detection

Application-Specific Engineering

Tesla Power routinely customizes gensets for:

- Data centers: Redundant fuel pumps, dual battery banks, sub-10-second transfer switch integration

- Healthcare facilities: Hospital-grade isolation transformers, automatic load shedding by priority, seismic mounting per local codes

- Industrial processes: Power factor correction, harmonic filtering for VFD loads, synchronization gear for peak shaving

This level of integration requires deep knowledge of both the Volvo Penta engine platform and the target application—expertise that separates professional manufacturers from assemblers.

Testing and Quality Assurance Protocols

Before a Volvo diesel generator leaves Tesla Power’s facility, it undergoes:

Factory Load Bank Testing

- Staged loading: 25%, 50%, 75%, 100%, 110% (for short-duration overload verification)

- Voltage/frequency regulation checks: Per ISO 8528-5 governing class requirements

- Temperature stabilization: Run at each load point until coolant, oil, and exhaust temperatures stabilize

- Acoustic measurement: dB(A) readings at multiple positions around the enclosure

System Commissioning

- Control system verification: Alarm points, shutdown logic, remote start/stop

- Paralleling logic testing (for multi-genset installations): Load sharing, reverse power protection, synchronization accuracy

- Transfer switch coordination: Simulated utility failure and restoration sequences

Documentation Package

Customers receive:

- Test run reports with actual performance data vs. specifications

- As-built drawings with dimensions and connection points

- Operation & maintenance manuals combining Volvo Penta engine docs with system-level procedures

- Warranty certificates covering engine (typically Volvo Penta direct) and system integration (manufacturer)

This rigor ensures the genset performs to specification on day one and provides a baseline for ongoing performance monitoring.

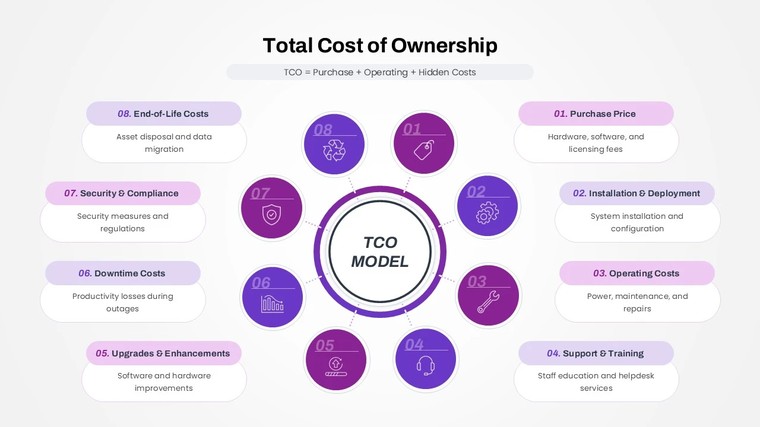

Transparent Pricing and TCO Analysis

Here’s a frustrating reality: many generator quotes are opaque. You get a price, maybe some specs, and little context for comparing alternatives.

What Tesla Power and Leading Manufacturers Provide

Professional Volvo diesel generator manufacturers offer:

Itemized Quotations: Breaking out engine cost, alternator cost, control system, enclosure, testing, freight, commissioning, and training. This transparency helps you understand where value is being added.

TCO Models: Projecting 10-20 year ownership costs including:

- Fuel (based on expected load profile and published SFC data)

- Scheduled maintenance (per Volvo Penta service intervals)

- Major overhauls (at projected hour milestones)

- Unscheduled repairs (industry averages for failure modes)

Performance Guarantees: Contractual commitments to power output, fuel consumption, noise levels, and emissions—with acceptance test procedures defined upfront.

The Value of Certainty

Yes, a Volvo diesel generator from Tesla Power will likely carry a 10-30% premium over a no-name Chinese genset. But when you factor in:

- Fuel savings (5-10% better SFC)

- Longer service intervals (500-1000 hour oil changes vs. 250 hours for lesser engines)

- Higher resale value (Volvo retains 40-50% of original value after 10,000 hours vs. 10-20% for obscure brands)

- Reduced downtime (from superior diagnostics and parts availability)

The TCO often favors Volvo by year three of operation. For prime power applications running thousands of hours annually, the payback is even faster.

Case Study: Mission-Critical Power for Manufacturing

Let me share a real-world scenario (details anonymized) that illustrates these differentiators in action.

The Challenge

A Midwest automotive parts manufacturer needed backup power for their CNC machining center—a facility running 24/6 with narrow profit margins. Their utility served a rural area prone to summer storm outages averaging 6-8 hours, twice yearly.

Unplanned shutdowns created:

- Scrap costs: ~$15,000 per event (in-process parts ruined)

- Recovery time: 4-6 hours to restart equipment and stabilize quality

- Expedite fees: Air freight to customers while catching up on orders

The Solution

Tesla Power specified a 500 kVA / 400 kW Volvo TAD1345GE-powered genset in a weather-resistant acoustic enclosure with:

- Automatic transfer switch with 10-second transfer time

- Remote monitoring via cellular gateway

- 1,000-liter integral subbase fuel tank (providing ~12 hours runtime at 75% load)

- Maintenance contract with 500-hour oil service and annual load bank testing

The Results (3-Year Mark)

- Zero unplanned outages: The genset handled 4 utility failures (total 26 hours of runtime)

- Fuel consumption: Averaged 82 L/h at ~70% load (within 2% of Volvo’s published curve)

- Maintenance costs: ~$3,200/year (routine services only; no component failures)

- ROI: System paid for itself in avoided scrap and expedite costs after the second utility failure (~18 months)

The manufacturer credited the EMS 2 diagnostics for catching a cooling system fault during a test run—a leak that, undetected, would have caused an overheat shutdown during the next real outage.

Navigating the Manufacturer Landscape

Not all “Volvo diesel generator manufacturers” are created equal. When evaluating vendors, ask these qualifying questions:

Engineering Capabilities

- “Do you have in-house engineers who perform load calculations and component sizing?”

- “Can I see examples of customized installations similar to my application?”

- “What design standards do you follow?” (Look for ISO, NFPA, NEMA, IEC references)

Quality Certifications

- “Are you an authorized Volvo Penta integrator?” (Not all dealers have factory authorization)

- “What quality management system do you operate?” (ISO 9001 is baseline for serious manufacturers)

- “Do you perform factory load bank testing on every unit?” (Ask to witness the test)

Service Infrastructure

- “Where is your nearest service depot to my facility?”

- “What is your average parts delivery time for common wear items?”

- “Do you offer extended warranty or maintenance contracts?” (Manufacturers confident in reliability offer these)

References and Track Record

- “Can you provide references in my industry?”

- “What is your installed base of Volvo-powered gensets?” (More units = more service experience)

- “How do you handle after-hours emergency calls?”

Tesla Power and peer manufacturers at the top tier will answer these confidently because they’ve invested in the infrastructure, training, and partnerships to deliver long-term value.

The Road Ahead: Volvo Penta’s Future in Power Generation

Looking forward, Volvo diesel generator manufacturers are positioning for the energy transition while maintaining diesel’s advantages for critical backup power.

Volvo Penta has certified multiple engine models for operation on HVO (Hydrotreated Vegetable Oil)—a drop-in renewable diesel offering up to 90% CO₂ reduction—and FAME biodiesel blends up to B20. This future-proofing lets Tesla Power install gensets today that can run on renewable fuels as they become economically viable.

Progressive manufacturers are also developing diesel-battery hybrid systems where a smaller Volvo genset handles baseload while batteries provide transient response, reducing fuel consumption by 20-40%. Tesla Power and others are leveraging EMS 2 data to build digital twin models that enable predictive maintenance, with early adopters reporting 30-50% reductions in maintenance labor.

Putting It All Together: The Value Proposition

So, what makes Volvo diesel generator manufacturers different? It boils down to core principles:

Engineering Discipline: Adherence to international standards, transparent ratings, and detailed performance documentation. You know exactly what you’re buying.

Purpose-Built Engines: Volvo Penta’s genset-specific design choices deliver reliability and longevity that automotive-derived engines can’t match in 24/7 duty.

Advanced Diagnostics: EMS 2 and CAN J1939 turn potential downtime into scheduled maintenance, protecting uptime and reducing lifecycle costs.

Fuel Efficiency: Published SFC curves and optimal load-band operation deliver measurable savings—often 5-10% vs. competitors, compounding year after year.

Global Support Infrastructure: Authorized service centers, parts availability, and factory technical support ensure you’re never stranded.

Durability and Rebuild Economics: Wet liners, replaceable valve trains, and overhaul-friendly design extend service life to 50,000+ hours across multiple rebuild cycles.

Comprehensive System Integration: Manufacturers like Tesla Power engineer complete power systems—not just engine + alternator—tailored to your application with testing and commissioning.

Transparent TCO: Itemized quotes, performance guarantees, and lifecycle cost modeling give you the information to make confident purchasing decisions.

For facilities where power reliability is non-negotiable—hospitals, data centers, manufacturing, water treatment, telecommunications—the premium you pay for a Volvo diesel generator from a reputable manufacturer like Tesla Power is an insurance policy that pays dividends through decades of dependable service.

Frequently Asked Questions

Q1: How long can a Volvo diesel generator run continuously without shutdown?

A Volvo diesel generator rated for prime power (PRP) per ISO 8528 can run continuously 24/7/365 at variable loads up to its rated capacity with no maximum hours-per-year limitation. The key is “variable load”—occasional periods of reduced load (even just 80-90% rather than 100%) allow components to cool and extend service intervals. For true baseload duty (100% rated power, 8,760 hours/year), consult the manufacturer about de-rating or specifying a continuous power (COP) rating if available.

Standby-rated generators, by contrast, are limited to 200 hours per year and should not see constant loads. Make sure your application matches your rating.

Q2: What is the typical maintenance schedule for a Volvo Penta genset engine?

Volvo Penta publishes detailed maintenance intervals based on operating hours and calendar time (whichever comes first):

- Oil and filter change: Every 500 hours or 6 months (can be extended to 1,000 hours with oil analysis approval)

- Fuel filter replacement: Every 500 hours or 6 months

- Air filter service: Every 500-1,000 hours depending on environment (dusty conditions = shorter interval)

- Coolant replacement: Every 2,000 hours or 2 years (using Volvo’s long-life coolant)

- Valve clearance check: First 500 hours (break-in), then every 6,000 hours

- Alternator bearing lubrication: Every 2,000 hours or annually

- Load bank test: Annually (to verify full-load capability and identify developing issues)

Major overhaul (rings, bearings, liners, valves) typically occurs at 15,000-20,000 hours depending on operating conditions and maintenance rigor. Your manufacturer like Tesla Power should provide a site-specific schedule during commissioning.

Q3: Can Volvo diesel generators run on biodiesel or renewable diesel fuels?

Yes, with caveats:

HVO (Hydrotreated Vegetable Oil / Renewable Diesel): Volvo Penta has approved HVO as a 100% drop-in replacement for fossil diesel in most modern engines (check specific model bulletins). HVO offers 90% CO₂ reduction, better cold-weather performance than biodiesel, and no fuel system modifications required.

FAME Biodiesel (e.g., B20): Volvo Penta approves blends up to B20 (20% biodiesel, 80% conventional diesel) in most engines. Higher blends (B50, B100) require special fuel system components and modified maintenance intervals due to FAME’s solvent properties and tendency to support microbial growth.

Action item: Confirm with your manufacturer (Tesla Power, etc.) that your specific engine model is approved for your intended fuel, and follow modified maintenance schedules (often requiring more frequent fuel filter changes with biodiesel).

Q4: How do Volvo diesel generators handle high-altitude or extreme-temperature installations?

Diesel engines experience power de-rating at high altitude and high temperatures due to reduced air density:

Altitude: Naturally aspirated diesels lose ~3-4% power per 1,000 feet above sea level. Turbocharged engines like Volvo Penta’s TAD series mitigate this better, but still see ~1-2% loss per 1,000 feet. At 5,000 feet elevation, expect ~5-10% de-rate.

High Temperature: For every 10°C above the standard reference condition (25°C), expect ~3-5% power loss.

Solution: Manufacturers like Tesla Power specify engine ratings and cooling systems for your actual site conditions. For example, a genset rated 500 kW at sea level and 25°C might be delivered with a 550-600 kW engine de-rated to meet 500 kW at your site’s altitude and summer peak temperature. The ISO 3046 standard provides correction factors to ensure accurate sizing.

Cold weather: Block heaters and battery warmers are standard for installations below -10°C to ensure reliable starting.

Q5: What is the expected lifespan and resale value of a Volvo diesel generator?

Lifespan: A well-maintained Volvo Penta engine in generator service typically delivers:

- First major overhaul: 15,000-20,000 hours

- Second rebuild cycle: 30,000-40,000 hours

- Potential end of life: 50,000+ hours (though many engines exceed this with comprehensive rebuilds)

For a standby genset running 50-100 hours/year (testing + occasional outages), that’s 30-50+ years of service. For a prime power genset running 4,000 hours/year, expect 12-15 years to first major overhaul, with potential total service life of 25+ years through rebuilds.

Resale value: Volvo-powered generators hold value significantly better than lesser brands:

- After 5,000 hours / 5-10 years (standby duty): 40-50% of original cost

- After 10,000 hours / 10-15 years: 30-40% of original cost

- After 20,000 hours: 20-30% of original cost (reflecting need for approaching overhaul)

This assumes maintenance records are available and the genset is still supported by current emissions regulations. Compare to generic Chinese gensets, which often fetch only 10-20% of original cost after 5,000 hours due to market skepticism about parts availability and remaining life.

Bottom line: When you invest in a Volvo diesel generator from Tesla Power, you’re buying an asset with decades of service potential and strong residual value—not a disposable commodity.