Picture this: It’s 2 a.m., and your manufacturing plant’s power suddenly cuts out. Production lines freeze. Temperature-controlled inventory starts warming. Your team scrambles in the dark. Then, within seconds, backup generators kick in—smooth, quiet, reliable. The crisis that could’ve cost hundreds of thousands in lost production becomes just a minor hiccup in the shift log.

That’s the promise of a well-chosen diesel generator—and increasingly, facility managers are turning to Volvo diesel generators for that critical backup role. But what exactly makes a Volvo-powered generator stand out in a crowded market of industrial generators? And more importantly, is it the right choice for your facility?

In this guide, we’ll walk through everything you need to know about Volvo Penta generator sets, from the engineering DNA that powers them to the real-world applications where they excel. Whether you’re specifying equipment for a new data center, upgrading hospital emergency systems, or ensuring your plant can ride out grid instabilities, understanding what sets Volvo generators apart will help you make a confident, informed decision.

What is a Volvo Diesel Generator?

First, let’s clear up some terminology. When people say “Volvo diesel generator,” they’re usually talking about a complete generator set (or “genset”) that uses a Volvo Penta engine as its power source.

Volvo Penta is the power systems division of the Volvo Group, specializing in engines for marine and industrial applications. They don’t typically build complete generators themselves. Instead, they supply high-performance diesel engines to Original Equipment Manufacturers (OEMs)—companies like KJ Power in Turkey, Dagartech in Spain, Starlight Power, Kohler, and Ingersoll Rand—who then integrate those engines with alternators, control systems, enclosures, and other components to create turnkey generator sets.

Think of it like this: Volvo Penta provides the heart (the engine), while the OEM builds the complete body (the generator set). The result is a Volvo diesel genset that carries the reliability and engineering heritage of the Volvo brand, tailored to specific industrial needs.

Key Components of a Volvo Diesel Generator

A complete Volvo Penta generator set typically includes:

- Volvo Penta Diesel Engine: The prime mover, usually from their TAD (inline) or TWD (V-configuration) industrial engine families

- Alternator: High-quality units from brands like Stamford, Leroy Somer, Marathon, or Mecc Alte, rated for industrial duty

- Control Panel: Advanced controllers from Deep Sea Electronics (DSE), ComAp, or similar manufacturers, providing monitoring, protection, and automatic start/stop

- Cooling System: Radiator and coolant circulation designed for the engine’s heat rejection requirements and ambient conditions

- Fuel System: Base tank or day tank, filters, and fuel management to support extended run times

- Enclosure (optional): Sound-attenuated canopy for outdoor installation or noise-sensitive environments

- Mounting Frame: Heavy-duty steel base frame, sometimes with integrated fuel tank

When you purchase a Volvo diesel generator from a reputable OEM or through an authorized dealer, you’re getting a fully integrated system where all these components work together seamlessly.

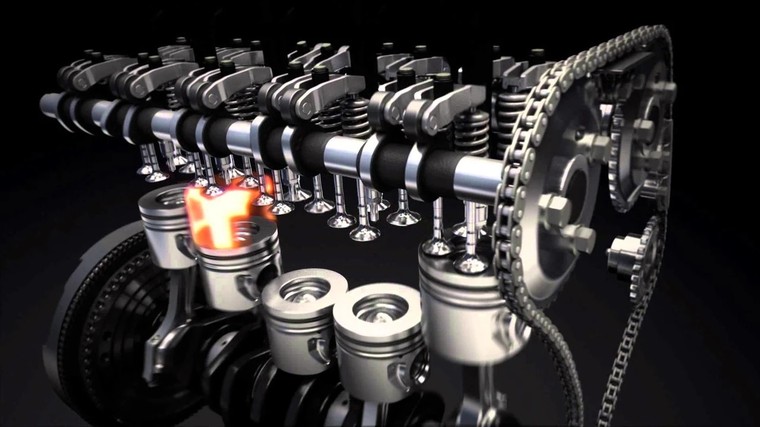

The Engine at the Heart: Volvo Penta’s Industrial DNA

Volvo Penta engines have been powering boats, construction equipment, and industrial generators for decades. Their industrial engine lineup—particularly the TAD and TWD series—is purpose-built for power generation, not adapted from truck or marine applications.

What makes these engines stand out? Several engineering choices contribute to their reputation:

Robust Block and Bottom End: Volvo Penta uses heavy-duty cast iron blocks and forged steel components in high-stress areas. This isn’t lightweight automotive engineering; it’s designed for 25,000+ hours of operation.

Fuel Efficiency: Advanced common-rail fuel injection and combustion chamber design mean Volvo engines typically consume 5-10% less fuel than comparable legacy designs at similar loads. Over a generator’s lifetime, that translates to significant savings in operating costs.

Load Acceptance: Standby power systems need to handle sudden, heavy loads without stalling or damaging the engine. Volvo Penta’s electronic governor systems and turbocharger matching allow their engines to accept large block loads with minimal frequency droop, critical for starting motors and other high-inrush equipment.

Emissions Compliance: Depending on your region and application, you might need to meet EPA Tier 3/4 or EU Stage IIIA/V standards. Volvo offers engine configurations across the spectrum, from Tier 2 for stationary emergency use (where exemptions apply) to fully Tier 4 Final compliant units with diesel particulate filters (DPF) and selective catalytic reduction (SCR) for non-emergency or mobile applications.

Global Service Network: Because Volvo Penta is part of the Volvo Group, parts availability and technical support span over 130 countries through approximately 3,500 dealers. If your operation has multiple sites or international locations, this global footprint is a real advantage.

At Tesla Power, we’ve installed Volvo-powered generators in facilities from coast to coast, and one theme consistently comes up in client feedback: reliability. These engines start when you need them and run as long as you need them to, with predictable maintenance intervals that fit into facility schedules without surprises.

Technical Specifications Deep Dive

Let’s get into the numbers. Understanding the specifications helps you match a Volvo diesel generator to your facility’s needs.

Power Ratings and Capacity

Volvo Penta generator sets are available across a broad power range, typically from around 64 kW (85 kVA) up to 750+ kW (1,000+ kVA), depending on the OEM and configuration.

Understanding kW vs. kVA

You’ll see generator capacity expressed in two units:

- kW (kilowatts): Real power—the actual work the generator can do

- kVA (kilovolt-amperes): Apparent power—kW divided by power factor

Most industrial loads have a power factor between 0.8 and 1.0. A 500 kVA generator at 0.8 power factor delivers 400 kW of real power. Always specify your loads in kW to avoid undersizing.

Standby vs. Prime vs. Continuous Ratings

Volvo engines—like all generator engines—are rated for different duty cycles under ISO 8528 standards:

- Standby Power (ESP): Maximum output available for emergency use, limited to 200 hours per year with a maximum of 25 hours continuous run. Typical for backup emergency power solutions in commercial buildings.

- Prime Power (PRP): Continuous power available for unlimited hours per year, with a 10% overload capacity for 1 hour in every 12. Used where the generator runs regularly but isn’t the sole power source.

- Continuous Power (COP): Base load power for 8,760 hours per year with no overload capacity. Rare in Volvo genset applications, more common in base-load or combined heat and power (CHP) setups.

Always clarify which rating you’re specifying. A 500 kW standby unit might only be rated for 450 kW prime—confusing these can lead to overloading and premature failure.

Engine Specifications: TAD and TWD Series

Volvo Penta’s industrial generator engines fall into two main families:

TAD Series (inline configurations):

- TAD734GE: ~200 kW standby

- TAD941GE: ~275 kW standby

- TAD1342GE: ~350 kW standby

- TAD1643GE: ~450 kW standby

TWD Series (V-configuration for higher power):

- TWD1643GE: ~500 kW standby

- TWD1653GE: ~550 kW standby

These engines feature:

- Displacement: 7.7L to 16.1L depending on model

- Aspiration: Turbocharged and intercooled (air-to-air or air-to-water)

- Governor: Electronic, maintaining frequency within ±0.25% in droop mode or isochronous for single-unit installations

- Cooling: Radiator cooling with engine-driven fan; some models offer separate cooling circuits for high-ambient operation

Alternator and Electrical System

Reputable OEMs pair Volvo engines with industrial-grade alternators:

- Brands: Stamford, Leroy Somer, Marathon, Mecc Alte

- Voltage: Configurable for 208V, 240V, 480V, 600V (North America) or 400V, 690V (international)

- Insulation Class: Typically Class H (180°C) for longevity

- Motor Starting Performance: Specified as maximum motor starting kVA the alternator can handle, usually 2.5-3.0 times the standby kVA rating for a single-step start at 35% voltage dip

The controller—usually a DSE or ComAp unit—provides:

- Voltage and frequency regulation

- Engine protections (low oil pressure, high coolant temp, overcrank, etc.)

- Auto start/stop on utility failure or restoration

- Remote monitoring via Ethernet or cellular (optional)

- Synchronization and load-sharing for paralleled setups (optional)

Fuel Consumption

One of Volvo’s strengths is generator fuel efficiency. Typical consumption for a Volvo diesel generator at 75% load:

- 200 kW unit: ~12-14 gallons per hour (gph)

- 400 kW unit: ~24-28 gph

- 600 kW unit: ~36-40 gph

These figures can vary based on specific engine model, load profile, and site conditions (altitude, temperature). Fuel efficiency not only reduces operating costs but also extends run time on a given tank size—critical for extended outages.

Noise Levels

Open (non-enclosed) Volvo generators typically operate at 95-105 dB(A) at 1 meter. For installations where noise is a concern—near residential areas, hospitals, or office buildings—OEMs offer sound-attenuated enclosures:

- Standard canopy: ~75-80 dB(A) at 1 meter

- Super-silent canopy: ~65-70 dB(A) at 1 meter

Quieter enclosures add cost and reduce heat dissipation capacity, so balance noise requirements against budget and installation constraints.

Emissions and Environmental Compliance

Volvo Penta engines are available in multiple emissions tiers:

- Tier 2 / Stage II: Common for stationary emergency standby (exempt from non-road mobile source rules in many jurisdictions)

- Tier 3 / Stage IIIA: Mid-level compliance for non-emergency stationary or older mobile applications

- Tier 4 Final / Stage V: Full emissions control with DPF and SCR, required for non-emergency stationary use in many regions and all new non-road mobile equipment

Higher-tier engines cost more upfront and require diesel exhaust fluid (DEF) and periodic filter regeneration, but they unlock applications where lower-tier engines can’t be legally deployed.

Applications by Industry: Where Volvo Generators Excel

Volvo diesel generators serve a diverse range of industries. Here’s where we commonly see them deployed, based on Tesla Power‘s installation portfolio:

Data Centers and IT Infrastructure

Data centers can’t tolerate even seconds of downtime. Volvo generators provide:

- Rapid start: Engine cranking to full voltage in under 10 seconds

- Stable frequency: Tight governor control prevents brownouts that crash servers

- Extended runtime: Fuel-efficient engines support multi-day outages common in severe weather

- Tier 4 options: Many urban data centers need low-emission engines to satisfy local air quality permits

We typically specify prime power generators rated at 1.25x the UPS load for data centers, allowing for future growth and N+1 redundancy.

Healthcare Facilities

Hospitals, surgical centers, and nursing homes fall under NFPA 70 Article 700 (emergency systems) and Article 517 (health care facilities). Requirements include:

- 10-second transfer: Generator must restore power to life-safety loads within 10 seconds of utility failure

- Minimum runtime: Sufficient fuel for 48-96 hours depending on jurisdiction

- Testing: Monthly no-load and annual load bank testing, which Volvo engines handle without complaint

Volvo Penta generator sets in the 300-750 kW range are popular for community hospitals and medical office buildings, offering the reliability demanded by critical care environments.

Manufacturing and Industrial Plants

Production facilities face massive costs when lines go down. A typical automotive parts plant loses $50,000+ per hour of unplanned downtime. Applications include:

- Emergency backup: Keeping ventilation, material handling, and control systems running during utility outages

- Peak shaving: Running generators during high-demand periods to reduce utility demand charges (requires prime-rated units)

- Power factor correction: Generators can help smooth reactive loads from motors and welding equipment

Industrial plants often have large motor starting loads (conveyor systems, compressors, pumps). Volvo engines’ excellent transient response and high alternator starting kVA ratings make them well-suited for these demanding applications.

Commercial Real Estate and High-Rises

Office buildings, hotels, and residential towers need backup power for:

- Life safety (fire pumps, emergency lighting, elevators)

- Tenant comfort (HVAC, security systems)

- Amenities (data/telecom rooms, kitchen equipment)

Most commercial buildings use standby-rated Volvo diesel gensets in the 150-500 kW range, often installed on rooftops in sound-attenuated enclosures to meet local noise ordinances (typically 65-75 dB(A) at the property line).

Construction and Rental Fleets

Volvo-powered mobile generators serve temporary power needs:

- Job sites: Powering tools, lighting, and temporary offices before permanent utility service

- Events: Concerts, festivals, outdoor weddings

- Disaster response: FEMA deployments, utility restoration, temporary hospital power

Rental-grade Volvo gensets usually feature heavy-duty trailer frames, large fuel tanks (24+ hour runtime), and rugged enclosures. Because rental units move frequently and face varied loads, the reliability and durability of Volvo engines are particularly valued in this market.

Agriculture and Remote Operations

Farms, ranches, and remote industrial sites (mining, oil/gas) often lack reliable grid power. Prime power generators with Volvo engines provide:

- Continuous operation: 8,760 hours per year capability for sites with no utility connection

- Variable load management: Handling everything from irrigation pumps to grain dryers with wildly varying demand

- Harsh environment tolerance: Operating in dusty, high-altitude, or extreme temperature conditions

The fuel efficiency of Volvo engines reduces the logistics burden of refueling remote sites—a critical advantage when the nearest fuel delivery is 50+ miles away.

Why Choose Volvo Penta Technology?

You have dozens of engine brands to choose from—Cummins, CAT, John Deere, Perkins, MTU, and more. So why do so many specifiers and end-users choose Volvo?

Proven Track Record

Volvo Penta has been in the power business for over 100 years. Their engines aren’t experimental; they’re field-proven across millions of operating hours in some of the world’s harshest environments. When you specify a Volvo diesel generator, you’re banking on a century of refinement.

Total Cost of Ownership

Upfront purchase price matters, but smart buyers focus on total cost of ownership (TCO):

- Fuel efficiency: 5-10% better than legacy competitors means thousands saved annually on a continuously running prime unit

- Maintenance intervals: Volvo’s 500-hour oil change intervals (under normal conditions) reduce service frequency and labor costs

- Parts availability: Global distribution means less downtime waiting for critical parts

- Resale value: Well-maintained Volvo generators hold their value better than less-recognized brands

Engineering for Reliability

Volvo doesn’t chase the absolute highest power density or the cheapest build cost. They design for reliability:

- Generous bearing surfaces and lubrication

- Conservative thermal limits to prevent hotspots

- Robust electrical systems designed for thousands of start cycles

- Proven components rather than bleeding-edge tech

This philosophy translates to fewer emergency service calls—and fewer 3 a.m. wake-up alerts telling you the generator won’t start.

Manufacturer Support

Because Volvo Penta is part of a larger corporate structure, they invest heavily in:

- Technical documentation: Comprehensive service manuals, parts lists, and troubleshooting guides

- Training programs: Dealer technicians receive ongoing education on new models and diagnostic techniques

- Warranty support: Clear warranty terms and responsive claims handling

- Product development: Continuous improvement driven by field feedback and evolving regulations

When you buy a Volvo Penta generator set, you’re not just buying hardware—you’re buying into a support ecosystem.

Making Your Decision: Is a Volvo Generator Right for You?

By now you understand the technical strengths and application fit for Volvo diesel generators. Here’s a simple decision framework:

Consider a Volvo-powered generator if:

- Reliability is non-negotiable: Your facility can’t afford generator failures during utility outages

- You value fuel efficiency: Operating costs over 10-15 years matter more than saving a few thousand on purchase price

- You need proven compliance: Volvo’s range of emissions tiers makes it easy to match local regulations

- You operate internationally: Global parts and service network supports multi-site operations

- You plan to hold the asset long-term: Volvo’s durability and resale value reward long ownership

You might look elsewhere if:

- Budget is the only factor: If initial cost is your sole criterion, commodity brands may undercut Volvo on price

- You need ultra-compact packaging: Some competitors offer higher power density in smaller frames (at the cost of service accessibility)

- You’re locked into an existing brand ecosystem: If your maintenance team is trained exclusively on another brand and you have extensive parts inventory, switching may not make economic sense

How to Get Started

If you’re ready to explore Volvo Penta generator sets for your facility:

- Define your requirements: Standby or prime rating? Power capacity (in kW, not just kVA)? Emissions tier? Indoor or outdoor installation? Noise limits?

- Consult with an experienced integrator: Companies like Tesla Power can help you navigate OEM options, size your system correctly, and coordinate permitting and installation.

- Request quotes from multiple OEMs: Compare not just price, but also alternator brand, controller features, enclosure quality, warranty terms, and local service availability.

- Verify dealer support: Confirm that authorized Volvo Penta dealers in your area can provide maintenance and emergency service.

- Plan for lifecycle costs: Don’t just budget for the purchase—factor in annual maintenance ($1,500-$5,000 depending on size), fuel for testing, and eventual overhaul or replacement.

The right diesel generator is an insurance policy you hope never to use but depend on completely when you do. Volvo Penta’s engineering philosophy—prioritizing reliability, efficiency, and supportability over cutting costs—aligns well with that mission-critical role.

Frequently Asked Questions

What is the typical lifespan of a Volvo diesel generator?

With proper maintenance, a Volvo Penta engine in standby service (limited annual hours) can last 25,000-30,000 hours or more—often 20+ years. Prime-duty units running continuously will reach major overhaul intervals around 15,000-20,000 hours. Regular oil changes, coolant service, and valve adjustments per the manufacturer’s schedule are critical to achieving these lifespans.

Can Volvo generators run on alternative fuels like biodiesel or HVO?

Yes. Many Volvo Penta engines are approved for biodiesel blends up to B20 (20% biodiesel, 80% petroleum diesel) and some models are certified for HVO100 (100% hydrotreated vegetable oil), a renewable diesel that significantly reduces carbon emissions. Always check the specific engine model’s fuel compatibility and follow Volvo’s guidelines to maintain warranty coverage.

How do Volvo diesel generators compare to natural gas generators?

Volvo diesel generators offer faster start times (seconds vs. minutes for some gas engines), better transient load response, and no reliance on utility gas lines that may fail during the same event that knocks out electric power. Diesel also stores indefinitely with proper fuel treatment, whereas natural gas systems require continuous utility supply. However, natural gas generators can have lower emissions in some configurations and eliminate on-site fuel storage. The choice depends on your site’s specific conditions and regulatory environment.

What maintenance is required for a Volvo diesel generator?

Routine maintenance includes oil and filter changes every 500 hours (or annually, whichever comes first for standby units), coolant system service every 2-3 years, air filter replacement, fuel filter changes, battery checks, and periodic valve adjustments. Additionally, you’ll need monthly no-load test runs (30 minutes) and annual load bank testing to meet NFPA codes for emergency systems. Budget $1,500-$5,000 per year depending on generator size and run hours.

Where can I buy a Volvo diesel generator?

Volvo Penta doesn’t sell directly to end users. Instead, purchase through authorized OEM diesel generator manufacturers (like KJ Power, Dagartech, Starlight, Kohler, Ingersoll Rand, or Innotech Energy) or through authorized distributors and dealers. Use the Volvo Penta dealer locator on their website to find local representatives who can provide quotes, installation, and service. Working with experienced integrators like Tesla Power can also simplify the procurement process and ensure proper system design.

Looking for expert guidance on specifying and installing Volvo diesel generators for your facility? Tesla Power brings over a decade of experience in industrial power systems, helping clients from data centers to manufacturing plants make confident, informed decisions. Contact us today to discuss your backup power needs.