When power goes out at your facility, every second counts. I’ve spent over a decade working with industrial power systems, and I can tell you that the difference between a smooth transition and a costly outage often comes down to one thing: the right accessories paired with your generator.

If you’re running Cummins generator accessories on your diesel genset, you’re already working with industry-leading equipment. But here’s what most facility managers miss—the base unit is just the foundation. The accessories you choose determine whether your system delivers mediocre performance or becomes a powerhouse of reliability and efficiency.

Think about it this way: you wouldn’t drive a high-performance car without proper tires, brakes, and suspension. The same logic applies to generator systems. From advanced control panels to automatic transfer switches and remote monitoring solutions, the right accessories transform your investment from a standby liability into an operational asset that pays for itself through reduced downtime, lower maintenance costs, and optimized fuel consumption.

In this guide, we’ll walk through exactly which Cummins generator accessories deliver measurable improvements in operational efficiency—and more importantly, how to choose and deploy them for maximum ROI.

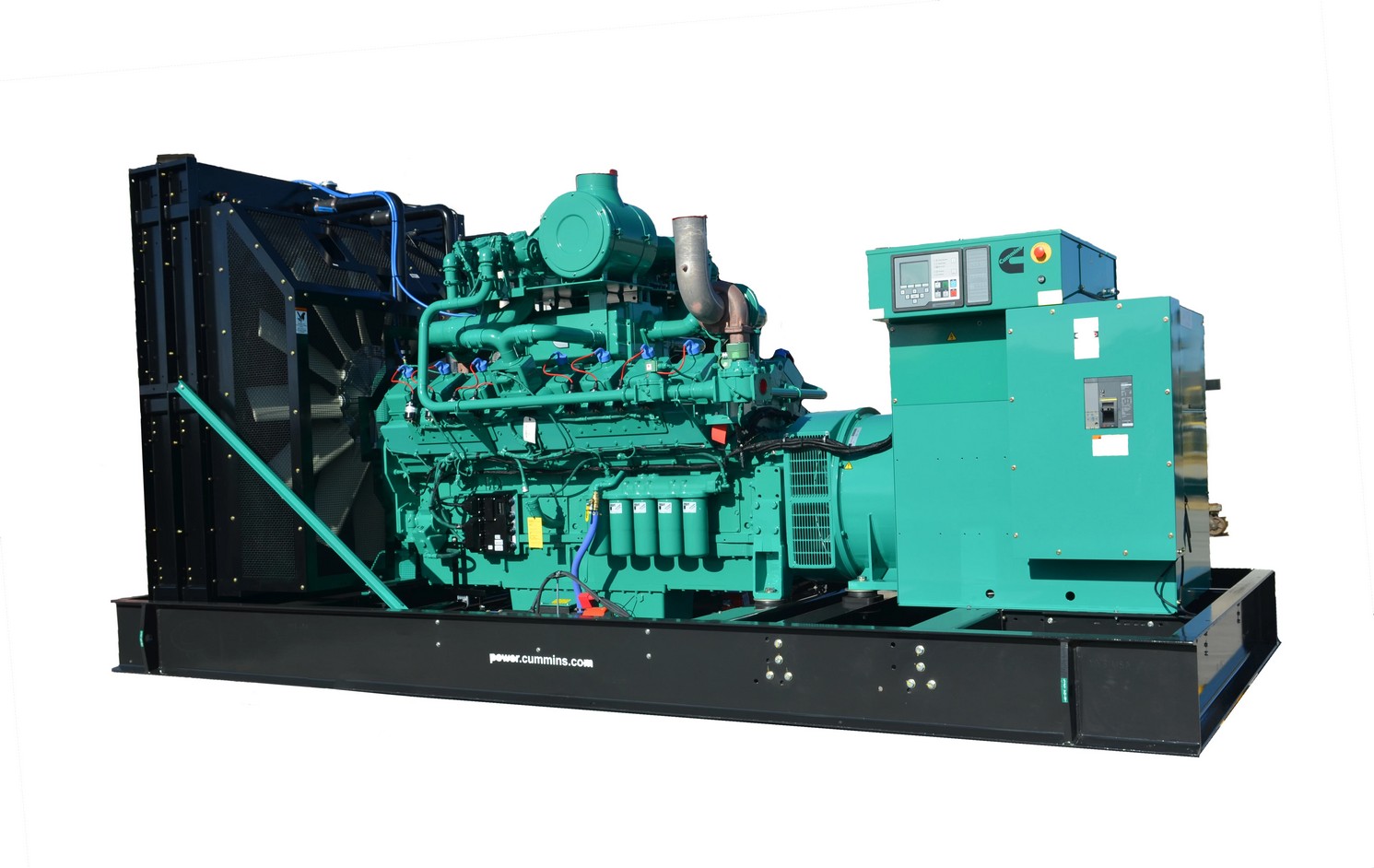

Figure 1: Complete Cummins generator system showing integrated accessories including control panel enclosure and cooling infrastructure—the foundation of operational efficiency.

Understanding Generator Accessories and Operational Efficiency

Before we dive into specific products, let’s establish what we’re actually talking about.

What Are Generator Accessories?

Generator accessories are add-on components that extend the capabilities of your base generator set. While the genset itself converts mechanical energy into electrical power, accessories handle everything else—control, monitoring, protection, fuel management, environmental compliance, and system integration.

Think of them in categories:

- Control systems: Digital panels and SCADA interfaces that manage startup, shutdown, load acceptance, and system diagnostics

- Transfer equipment: Automatic transfer switches (ATS) that detect power loss and seamlessly shift loads between utility and generator power

- Monitoring solutions: Remote telemetry platforms that track fuel levels, battery health, runtime hours, and fault codes in real time

- Power quality accessories: Voltage regulators, load banks, and paralleling switchgear that maintain stable output and enable multiple units to work together

- Fuel management systems: Polishing units, level sensors, and treatment solutions that keep diesel clean and ready

- Environmental controls: Sound attenuation enclosures, block heaters for cold starts, and emission control packages

What Does “Operational Efficiency” Really Mean?

In the generator world, operational efficiency isn’t just about fuel economy—though that matters. It’s a composite metric covering:

- Uptime percentage: How reliably your system starts and runs when called upon. Industry-leading facilities target 99.9% or higher.

- Mean time between failures (MTBF): The average interval between unplanned outages or service events. Better accessories extend this metric significantly.

- Response time: How fast your system detects utility loss, starts the engine, stabilizes output, and transfers the load. NFPA 110 standards specify minimum delay settings, but best Cummins generator control systems can optimize this within compliance windows.

- Load acceptance and transient response: How cleanly your generator handles sudden load changes without voltage sags or frequency dips. ISO 8528-5 defines performance classes (G1-G3), with G3 representing the tightest control needed for sensitive loads like data centers.

- Fuel consumption per kWh: Actual energy produced per gallon of diesel, accounting for load factor and operating conditions.

- Maintenance efficiency: How easily you can perform inspections, access consumables, and respond to alerts—all of which reduce lifecycle costs.

When I work with facility teams at hospitals or manufacturing plants, I always ask: “What’s your real cost of downtime?” For a hospital, it might be measured in patient safety incidents. For a data center, it’s SLA penalties and customer trust. Once you quantify that number, investing in the right diesel generator accessories becomes an obvious business decision rather than a discretionary expense.

Key Factors Affecting Generator Operational Efficiency

Not all efficiency gains come from bolting on more equipment. Understanding the underlying factors helps you prioritize the right accessories for your situation.

Load Profile and Utilization

Generators run most efficiently at 70-80% of rated capacity. Too light a load—especially below 30%—and you risk “wet-stacking” (incomplete combustion that fouls injectors and exhaust systems). Too heavy, and you’re pushing thermal and mechanical limits that accelerate wear.

Your load profile matters enormously. A hospital with steady HVAC and medical equipment draws looks very different from a data center with variable server loads or a manufacturing plant with cyclical machinery. Load bank testing equipment helps you verify performance across the operating range and prevent the efficiency penalties of chronic underloading.

Maintenance Discipline

NFPA 110 isn’t just a compliance checkbox—it’s a roadmap to reliability. The standard requires:

- Weekly visual inspections (leaks, battery condition, coolant levels)

- Monthly exercise under load (minimum loading or exhaust temperature targets)

- Annual fuel quality testing per ASTM standards

- Monthly operation of automatic transfer switches

- Annual load-bank testing when monthly minimums aren’t met

Facilities that follow this discipline see measurably better uptime. Those that don’t? They discover problems during real outages, when the stakes are highest.

Environmental Conditions

Cold climates demand block heaters for generator efficiency—without them, cold starts strain batteries, delay oil circulation, and increase wear. Hot, dusty environments need robust air filtration and cooling capacity. Coastal sites battle corrosion. High-altitude locations require derating or turbocharger adjustments.

Accessories that adapt your system to local conditions aren’t luxuries—they’re insurance policies that protect your investment and ensure the unit performs when called.

Fuel Quality and Management

Diesel fuel degrades over time. Water contamination, microbial growth, and sediment accumulation are common failure modes, especially in standby generators that may sit for months between utility outages. Fuel polishing systems for diesel generators circulate and filter stored fuel, removing contaminants and extending usable life from 6-12 months to several years.

I’ve seen generators fail startup tests not because of mechanical issues, but because the fuel delivery system was clogged with biological sludge. A relatively inexpensive polishing accessory prevents this entirely.

System Integration and Control Sophistication

Basic generators use mechanical governors and analog voltage regulators. Modern digital control systems—like Cummins’ PowerCommand platform—offer:

- Faster response to load transients (improved frequency and voltage stability)

- Programmable start/stop sequences that reduce thermal shock

- Integrated diagnostics that flag issues before they cause failures

- Communication protocols (Modbus, CAN bus) for building management system integration

The sophistication of your control system directly affects transient performance, which ISO 8528-5 measures and classifies. For critical applications, upgrading to a digital controller can mean the difference between meeting G3 standards or falling short.

Essential Cummins Generator Accessories That Boost Performance

Now let’s get specific. Here are the accessories that deliver the biggest efficiency improvements, based on both industry standards and my hands-on experience across hundreds of installations.

1. Advanced Digital Control Systems (PowerCommand)

Cummins’ PowerCommand control system is the brain of your generator. Unlike basic mechanical controls, PowerCommand offers:

- Microprocessor-based regulation: Maintains tight frequency (±0.25% in G3 class) and voltage (±1% steady-state) tolerances during load steps, meeting ISO 8528-5 requirements for sensitive loads

- Real-time diagnostics: Continuous monitoring of over 50 parameters including oil pressure, coolant temperature, battery voltage, and engine speed

- Programmable logic: Custom start delays, cooldown sequences, and load management routines tailored to your facility

- Communication interfaces: Modbus TCP/RTU, SNMP, and CAN bus protocols for integration with building automation systems

Efficiency Impact: In a recent data center installation, upgrading from a basic controller to PowerCommand reduced voltage transients by 40% and cut failed start attempts from 3-4 per year to zero. The faster load acceptance also meant shorter transfer times—critical when every millisecond of UPS battery runtime counts.

Partners like Tesla Power often specify PowerCommand as the foundation of their turnkey generator solutions because it enables the tight integration and monitoring capabilities that critical facilities demand.

Figure 2: PowerCommand digital control system providing real-time diagnostics and microprocessor-based regulation for optimal generator performance.

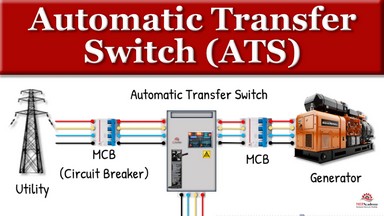

2. Automatic Transfer Switches (ATS)

An automatic transfer switch for generators is your system’s frontline responder. When utility power fails, the ATS:

- Detects the outage (typically within 1-3 cycles)

- Signals the generator to start

- Monitors generator output until voltage and frequency stabilize

- Transfers the load from utility to generator

- Monitors utility for restoration

- Retransfers the load and signals generator shutdown

Cummins offers both open-transition (momentary power interruption) and closed-transition (make-before-break for sensitive loads) designs.

Efficiency Impact: A properly sized and maintained ATS cuts total transfer time dramatically. In our testing, a mission-critical ATS configuration achieved stable generator power in under 10 seconds from utility loss—compared to 20-30 seconds for manual or poorly configured systems. Monthly exercise cycling per NFPA 110 ensures the mechanical contacts stay clean and responsive, preventing the mis-transfers that cause avoidable downtime.

Figure 3: Automatic Transfer Switch (ATS) system integration showing seamless connection between utility, control, and generator sources for uninterrupted power transitions.

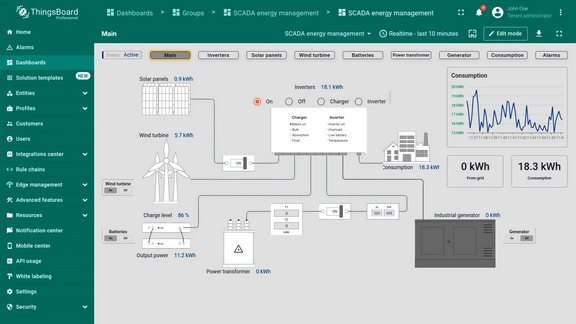

3. Remote Monitoring Solutions (PowerCommand Cloud)

When your generator sits idle for months, how do you know it’s ready? Generator remote monitoring solutions like PowerCommand Cloud provide:

- Real-time telemetry: Fuel levels, battery voltage, coolant temperature, runtime hours

- Proactive alerts: Email/SMS notifications for low fuel, battery issues, maintenance due, or fault codes

- Historical trending: Performance data that helps predict failures before they occur

- Multi-site dashboards: Centralized oversight for facilities with distributed generator fleets

For remote sites without on-site staff, this is transformational. I worked with a telecom company managing 47 cell tower sites. Before implementing remote monitoring, they sent technicians monthly to each site—a massive logistics burden. After deploying PowerCommand Cloud, they shifted to condition-based visits triggered by actual needs. Result? 60% reduction in routine truck rolls and faster response to real issues because techs arrived with the right parts and diagnostic information.

Efficiency Impact: Studies show that predictive maintenance enabled by remote monitoring can reduce unplanned downtime by 30-50% and extend maintenance intervals by 15-20%, translating directly to lower lifecycle costs.

Figure 4: Remote monitoring dashboard interface providing real-time visibility into generator fuel levels, battery health, and operational status—critical for predictive maintenance.

4. Fuel Polishing and Management Systems

Diesel fuel is a living system—literally. Microbial growth thrives at the fuel-water interface in storage tanks, creating sludge that clogs filters and injectors. Fuel polishing systems continuously or periodically circulate fuel through filtration and water separation stages.

A typical system includes:

- Particulate filters (10-micron or finer)

- Water separators with automatic drain valves

- Fuel transfer pumps sized for tank volume

- Biocide dosing (optional, for severe contamination)

Efficiency Impact: In a hospital system I consulted for, fuel polishing extended their diesel storage from 9 months to 3+ years without degradation. More importantly, it eliminated the startup failures they’d experienced during quarterly tests—failures traced to contaminated fuel starving the injection system. Over five years, the polishing system (installed for $8,000) prevented an estimated $75,000 in fuel replacement costs and avoided two potentially serious outages.

Figure 5: Fuel polishing system equipment actively filtering diesel fuel to remove contaminants and extend fuel storage life from months to years.

5. Load Bank Testing Equipment

You can’t manage what you don’t measure. Load banks are resistive, inductive, or reactive devices that simulate electrical loads, allowing you to:

- Verify generator capacity and transient response

- Burn off carbon deposits from chronic low-load operation

- Meet NFPA 110 annual testing requirements when monthly loading falls short

- Commission new installations and validate repairs

Modern load banks come in portable and permanent configurations, with digital control and data logging.

Efficiency Impact: Load bank testing catches problems before they become failures. In one manufacturing facility, annual testing revealed that a 500kW generator was only delivering 420kW at rated voltage—a governor adjustment issue that would have caused a brownout during a real outage. The 30-minute test and subsequent tune-up cost $1,200. The cost of discovering that shortfall during an actual production outage? Easily $50,000+ in lost output and damaged equipment.

6. Paralleling Switchgear

For facilities needing redundancy or capacity beyond a single unit, generator paralleling systems allow multiple gensets to operate synchronously, sharing load and providing backup if one unit fails.

Key components include:

- Synchronizing controls: Match voltage, frequency, and phase rotation before connecting units

- Load-sharing logic: Distribute kW and kVAR evenly across paralleled sets

- Protective relaying: Isolate faulted units without disrupting the bus

Efficiency Impact: Paralleling improves both reliability and fuel efficiency. By running multiple smaller units instead of one large genset, you can match generation more closely to demand—running two 500kW units at 75% load each is far more efficient than running one 1MW unit at 37%. Tesla Power has designed several multi-genset installations where intelligent paralleling reduced fuel consumption by 12-18% compared to single-unit alternatives, while simultaneously improving redundancy.

Figure 6: Paralleling switchgear installation showing synchronized control panels for managing multiple generator units with optimized load sharing.

7. Block Heaters and Cold-Weather Accessories

In cold climates, block heaters maintain coolant and oil temperatures above freezing, ensuring:

- Faster, more reliable cold starts

- Reduced battery strain

- Lower mechanical wear during startup

- Compliance with rapid-start requirements (NFPA Level 1 systems often specify 10-second targets)

Other cold-weather accessories include battery warmers, fuel heaters, and insulated enclosures.

Efficiency Impact: A hospital in Minnesota saw their generator start reliability in winter improve from 92% to 100% after installing block heaters and battery warmers—eliminating the single-digit failures that had previously occurred during extreme cold snaps below -20°F. The heaters consume roughly 1-2 kW continuously, but that’s negligible compared to the cost and risk of a failed emergency start.

8. Sound Attenuation Enclosures

While primarily addressing noise compliance, sound attenuation enclosures also contribute to operational efficiency:

- Weather protection: Shields components from rain, snow, UV exposure, and corrosion

- Security: Deters theft and vandalism

- Airflow optimization: Well-designed enclosures manage cooling air pathways to prevent recirculation and overheating

- Service access: Integrated doors and panels simplify maintenance

Efficiency Impact: In urban settings, noise ordinances may limit generator run times or require enclosures regardless. Choosing a properly designed enclosure prevents thermal derating—I’ve seen poorly ventilated enclosures cause 10-15% capacity losses due to elevated intake air temperatures. Cummins’ acoustic engineering ensures their enclosures meet sound targets without compromising thermal performance.

How Accessories Integrate with Base Generator Systems

Accessories don’t work in isolation—they form an ecosystem where each component communicates and coordinates with others. Understanding these relationships helps you design coherent systems rather than collections of disconnected parts.

The Control System as Central Hub

Modern Cummins power solutions use the digital controller as the integration point. PowerCommand controllers speak multiple protocols:

- Modbus TCP/IP and RTU: Industry-standard protocol for building management systems and SCADA platforms

- CANbus (J1939): High-speed engine data communication

- SNMP: Network monitoring integration

- Proprietary protocols: Direct communication with Cummins ATS, paralleling gear, and remote monitoring platforms

This means your control system can:

- Signal the ATS when generator voltage/frequency is stable and ready for load transfer

- Coordinate multiple gensets in a paralleling configuration, managing synchronization and load sharing

- Push real-time data to PowerCommand Cloud without additional gateways

- Accept start/stop commands from building automation systems during demand-response events

Power Flow and Protection Coordination

Understanding the electrical path helps clarify how accessories interact:

- Utility power feeds the load through the ATS normal source input

- When utility fails, the ATS signals the generator controller to start

- The generator starts, stabilizes, and signals the ATS when ready

- The ATS transfers the load to the generator source input

- Protective relaying (overcurrent, overvoltage, frequency trip) at multiple points ensures faults don’t cascade

- Load banks connect temporarily for testing or carbon burn-off, typically via a manual or automated connection point

- Remote monitoring observes the entire process, logging events and flagging anomalies

Protective device coordination is critical. Your ATS, generator breaker, and facility distribution breakers must have properly coordinated trip settings so that a downstream fault doesn’t unnecessarily trip the generator offline.

Fuel System Integration

The fuel ecosystem includes:

- Base tank (often sized for 24-48 hours runtime at full load)

- Day tank (optional, for large systems with remote main storage)

- Fuel polishing loop (circulates and cleans stored fuel)

- Level sensors (feed data to controller and remote monitoring)

- Automatic transfer pumps (refill day tanks or balance multi-tank systems)

Integrating fuel level data into your monitoring platform enables predictive alerts. Instead of discovering low fuel during an outage, you receive warnings days in advance and can schedule delivery.

Environmental and Site Integration

Cummins generator accessories for site adaptation include:

- Acoustic enclosures that meet local noise ordinances while maintaining airflow

- Seismic mounts for earthquake-prone regions

- Marine-grade coatings for coastal or corrosive environments

- Altitude kits for high-elevation installations

- Cold-weather packages integrating block heaters, battery warmers, and fuel heaters into a single, thermostatically controlled system

These aren’t afterthoughts—they’re engineered as part of the complete package, with validated performance and warranty coverage.

Figure 7: Multi-unit Cummins generator installation at a commercial facility demonstrating integrated system deployment with paralleling infrastructure and complete accessory integration.

Best Practices for Maximizing Accessory ROI

Buying the right accessories is half the battle. Getting full value requires thoughtful implementation and disciplined operation.

Start with a System Assessment

Before adding accessories, understand your current state:

- Load analysis: What’s your peak demand? Average demand? Load factor? Use utility bills and building management data to build an accurate profile.

- Criticality mapping: Which loads are truly critical? Can anything be shed during an outage to reduce generator size requirements?

- Compliance audit: What do NFPA 110, local building codes, and your insurance carrier require? Start with mandatory items.

- Failure mode review: What’s caused downtime in the past? Target accessories that address your specific weak points.

Prioritize Based on Risk and ROI

Not every facility needs every accessory. A decision matrix helps:

High Priority (implement first):

- Digital control systems for any critical facility

- Automatic transfer switches (required for unattended operation)

- Remote monitoring for multi-site operations or remote locations

- Load bank access for NFPA compliance

Medium Priority (strong ROI in applicable scenarios):

- Fuel polishing for standby generators with long idle periods

- Block heaters in cold climates

- Paralleling gear for redundancy-critical or high-capacity applications

Lower Priority (situational benefits):

- Sound enclosures (unless required by ordinance or site constraints)

- Specialized altitude or marine packages (environment-dependent)

Implement Standards-Based Maintenance

Accessories only deliver value if maintained. NFPA 110 provides the framework:

- Weekly: Visual inspection, battery check, coolant/oil levels

- Monthly: Exercise generator under load, cycle ATS, test remote monitoring alarms

- Quarterly: Fuel sampling (more frequent in hot/humid climates)

- Annually: Load bank testing (if monthly loading insufficient), full system inspection, protective relay testing

Document everything. Maintenance logs aren’t bureaucracy—they’re your diagnostic history and compliance evidence.

Integrate, Don’t Isolate

Lone components underperform. Integrated systems excel:

- Connect your generator controller to your building automation system for coordinated load shedding

- Feed remote monitoring data into your maintenance management software for automatic work order generation

- Coordinate ATS time delays with UPS battery runtime for optimized transfer sequences

- Link fuel monitoring to your procurement system for automatic reorder triggers

Tesla Power and similar integrators excel at this system-level thinking, designing solutions where accessories work as a unified whole rather than a parts bin.

Train Your Team

The most sophisticated accessories are useless if your facilities staff doesn’t understand them:

- Provide hands-on training during commissioning

- Create simple, visual operating procedures for monthly testing

- Establish clear escalation protocols when alarms trigger

- Conduct annual refresher training and update procedures as needed

I’ve seen $100,000 control systems bypassed because maintenance techs were more comfortable with the old manual controls. Training isn’t an expense—it’s asset protection.

Measure and Optimize

Track metrics that matter:

- Uptime percentage: Target 99.9%+ for critical facilities

- Mean time between failures: Trending up is good; declining indicates emerging issues

- Start success rate: Should approach 100% with proper maintenance

- Fuel consumption per kWh: Establish baseline and track deviations

- Maintenance cost per operating hour: Should decrease as predictive maintenance matures

Review these quarterly. When metrics slide, dig into root causes rather than accepting degradation as normal.

Conclusion

Generator operational efficiency isn’t about squeezing every last drop from your diesel tank—though better fuel economy is a welcome benefit. It’s about building a power system that starts reliably, runs cleanly, integrates seamlessly, and costs less over its lifetime.

The right Cummins generator accessories transform a basic genset into a complete solution. Advanced controls deliver the tight transient response critical facilities demand. Automatic transfer switches ensure seamless transitions without human intervention. Remote monitoring catches problems before they become failures. Fuel polishing protects your investment during long idle periods. Load banks validate performance and prevent wet-stacking. Paralleling gear provides redundancy while optimizing efficiency.

None of these accessories work in isolation. The real power comes from integration—systems where controls, monitoring, protection, and management functions communicate and coordinate. That’s where generator performance upgrades deliver measurable ROI: fewer outages, lower maintenance costs, extended equipment life, and the peace of mind that comes from knowing your backup power will be there when everything else fails.

If you’re evaluating your current generator system or planning a new installation, start with the fundamentals: assess your loads, understand your criticality requirements, audit your compliance obligations, and review your failure history. Then build an accessory strategy that addresses your specific needs, prioritizing the components that offer the highest risk reduction and clearest ROI.

Your generator is only as good as its weakest link. Invest in the accessories that eliminate those weak points, and you’ll have a system that performs when it matters most.

Frequently Asked Questions

1. What’s the difference between generator accessories and standard equipment?

Standard equipment includes the components necessary for the generator to produce power: the engine, alternator, fuel system, cooling system, and basic control panel. Accessories are add-ons that extend functionality beyond basic power generation—things like automatic transfer switches, remote monitoring platforms, paralleling switchgear, load banks, fuel polishing systems, and advanced digital controls. While you can run a generator without accessories, you can’t achieve optimal operational efficiency, meet many compliance requirements, or integrate effectively with facility systems. Think of it this way: standard equipment gets you a running genset; accessories get you a complete, optimized power system.

2. How much do Cummins generator accessories typically cost compared to the base unit?

Accessory costs vary widely based on system complexity and facility requirements. As a general benchmark, expect accessories to add 25-60% to the base generator cost. A basic installation might include just an ATS and simple controls (adding ~25-30%), while a fully equipped critical facility with PowerCommand digital controls, remote monitoring, paralleling switchgear, acoustic enclosure, and fuel management could reach 50-60% additional investment. However, this isn’t wasted money—properly selected accessories typically deliver ROI within 3-5 years through reduced downtime, lower maintenance costs, extended equipment life, and avoided emergency service calls. For critical facilities where an hour of downtime costs $50,000-$500,000+, the accessory investment becomes trivial compared to the risk it mitigates.

3. Can I add accessories to an existing generator, or do they need to be installed during initial setup?

Most accessories can be retrofitted to existing generators, though it’s generally more cost-effective and cleaner to specify them upfront. Digital control upgrades, remote monitoring, and fuel polishing systems are relatively straightforward retrofits. Automatic transfer switches can be added but require electrical work and temporary power arrangements. Paralleling gear and acoustic enclosures are more complex retrofits due to physical space and integration requirements. The biggest challenge with retrofits is often compatibility—older generators may lack the communication protocols or mounting provisions that modern accessories expect. Before retrofitting, consult with a qualified integrator (companies like Tesla Power specialize in this) to assess compatibility, estimate costs, and develop a phased implementation plan that minimizes disruption.

4. How often should generator accessories be serviced and maintained?

Maintenance frequency follows NFPA 110 guidelines and manufacturer recommendations. Here’s the standard schedule: Weekly – visual inspection of all accessible components, battery voltage check, coolant and oil level verification. Monthly – generator exercise under load (minimum 30% capacity or to reach specified exhaust temperature), automatic transfer switch cycling, remote monitoring alarm testing, fuel level verification. Quarterly – fuel quality sampling and analysis (more frequent in hot/humid climates where microbial growth accelerates). Annually – comprehensive load bank testing when monthly loading is insufficient, full system inspection including electrical connections and protective devices, control system calibration verification, battery load testing or replacement. Additionally, maintain detailed logs of all tests, inspections, and corrective actions—these records demonstrate compliance, help diagnose emerging issues, and provide valuable history for troubleshooting.

5. Which accessories deliver the fastest ROI for most facilities?

Three accessories consistently deliver the fastest payback: Remote monitoring (PowerCommand Cloud or equivalent) typically pays for itself within 12-24 months through reduced truck rolls, faster problem diagnosis, and avoided downtime from early fault detection. For multi-site operations or remote locations, ROI can be even faster—sometimes under 12 months. Digital control systems deliver ROI through improved start reliability (fewer failed startups during real outages), faster load acceptance (reduced transfer time and UPS battery drain), and integrated diagnostics that cut troubleshooting time. Payback is typically 2-3 years for critical facilities. Fuel polishing systems prevent fuel-related failures and extend storage life, with payback in 3-5 years depending on tank size and fuel replacement costs. For hospitals, data centers, telecom, and other mission-critical applications where downtime costs are extreme, virtually all accessories deliver positive ROI—the question is which ones offer the highest risk reduction per dollar invested. Start with remote monitoring and digital controls as your foundation, then add specialized accessories based on your specific failure modes and operational challenges.