When the power goes out, your diesel generator becomes your facility’s lifeline. But walk into any industrial power showroom, and you’ll face a dizzying array of options: single-phase or three-phase? Standby or prime rated? Air-cooled or liquid-cooled? Open-frame or enclosed? Brand names like Cummins generators, Caterpillar, Kohler, and Tesla Power all promising reliability.

The wrong choice doesn’t just cost money—it can leave you stranded during the outage you bought the generator to survive. The right choice, on the other hand, delivers decades of dependable backup power at the lowest total cost of ownership.

This guide breaks down the key decisions you’ll face when specifying a diesel generator, with practical comparison frameworks to help you choose wisely.

Diesel vs. Natural Gas: The Fuel Decision

Your first fork in the road is fuel type. For standby power applications, diesel dominates—but natural gas has its place.

Diesel Advantages

Fuel storage and stability: Diesel stores safely on-site in simple steel tanks for 12-24 months with basic fuel treatment. Natural gas requires utility connection or expensive propane tanks with regular delivery.

Power density: Diesel generators deliver more power from smaller, lighter engines. A 100 kW diesel unit weighs 30-40% less than an equivalent natural gas unit.

Cold weather reliability: Diesel engines start reliably down to -20°F with block heaters. Natural gas can face pressure regulation issues and won’t start if the utility gas line is also down.

Efficiency: Diesel engines operate at 30-35% efficiency vs. 25-30% for natural gas. Over thousands of hours, that fuel cost difference compounds.

Natural Gas Advantages

Cleaner emissions: Natural gas burns cleaner, producing 20-30% less CO2 and virtually no particulate matter. Easier to permit in urban areas.

Unlimited runtime (grid-connected): As long as the gas utility is up, you have infinite fuel. No tank refills during extended outages.

Lower maintenance: No fuel tanks to inspect, no fuel polishing, no fuel-related injector problems. Maintenance intervals can be 30-40% longer.

Quieter operation: Natural gas engines run 3-5 dB quieter than diesel—matters for noise-sensitive locations.

The Verdict

For emergency generators and standby power, diesel wins on reliability and fuel independence. Hospitals, data centers, water treatment plants, and critical facilities almost universally choose diesel. For prime power in permanent off-grid installations with natural gas infrastructure, gas makes economic sense due to lower fuel costs over 5,000+ annual hours. Tesla Power and major manufacturers offer both—match the fuel to your application.

Air-Cooled vs. Liquid-Cooled: The Cooling System Decision

Cooling system design dramatically affects generator size, cost, maintenance, and lifespan.

Air-Cooled Generators

What they are: Air-cooled engines use fins and fans to dissipate heat, like a motorcycle engine.

Power range: Typically limited to 25 kW and below for diesel generators (though portable units go up to 40 kW).

Pros: Simpler design, fewer parts | No coolant to change, no radiators to clean | Lower initial cost ($3,000-$8,000 for 15-25 kW units) | More compact and portable

Cons: Noisier operation (80-85 dB) | Shorter lifespan (5,000-10,000 hours) | Temperature-sensitive (derate by 10-15% in hot climates) | Can’t sustain continuous high loads

Best for: Home backup, small shops, job sites, applications running <500 hours annually.

Liquid-Cooled Generators

What they are: Liquid-cooled engines use coolant circulation through a radiator, like automotive engines. All commercial generators above 25 kW use liquid cooling.

Power range: 25 kW to 3,000+ kW.

Pros: Much quieter (65-75 dB) | Longer lifespan (15,000-30,000 hours) | Better load handling and surge capacity | Stable operation across temperature extremes | Lower fuel consumption per kW

Cons: Higher initial cost ($12,000+ for 50 kW units) | More maintenance (coolant changes, hose inspections) | Larger physical footprint

Best for: Commercial facilities, industrial generators, any application requiring reliability over 10+ years or >1,000 hours annually.

The Verdict

For anything over 25 kW or commercial use, liquid-cooled is non-negotiable. A $15,000 liquid-cooled Cummins diesel generator will outlast three $5,000 air-cooled units and run quieter, cleaner, and more efficiently.

Single-Phase vs. Three-Phase: The Electrical Configuration

This isn’t a performance comparison—it’s a compatibility requirement. Your facility’s electrical service dictates which you need.

Single-Phase (120/240V)

What it is: Two hot legs and a neutral, delivering 120V or 240V. Standard residential and small commercial service.

Power limits: Practically limited to 50 kW. Above that, current draw becomes unmanageable (200A+ breakers).

Equipment: Lights, computers, small motors, residential appliances, office equipment.

When you need it: Homes, small offices, retail shops, light-duty workshops.

Three-Phase (208V, 480V, 600V)

What it is: Three hot legs delivering balanced power. Standard for commercial, industrial, and large facilities.

Power range: From 30 kW up to megawatts. Efficiently handles large motor loads.

Equipment: HVAC systems, elevators, industrial motors, CNC machines, commercial refrigeration, large UPS systems.

When you need it: Essentially any commercial building, manufacturing facility, hospital, data center, or site with motors over 5 HP.

The Verdict

No choice here—match your generator to your facility’s service. You can’t power three-phase equipment with a single-phase generator (without expensive phase converters that waste 15-25% of power). Check your main service panel. If you see three breakers ganged together, you have three-phase service and need a three-phase generator.

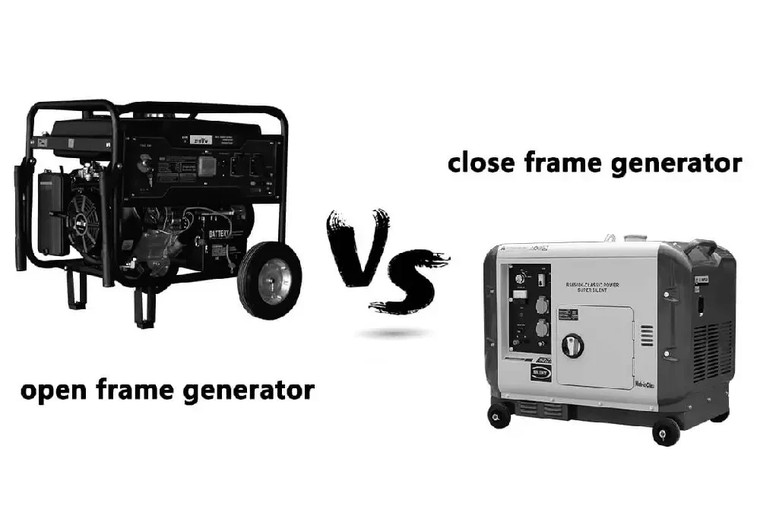

Open vs. Enclosed: The Housing Decision

Your generator needs protection from weather, noise containment, and physical security. Housing type affects cost, maintenance access, noise levels, and space requirements.

Open-Frame Generators

What they are: Engine and alternator mounted on a steel skid frame, fully exposed.

Cost: Least expensive. A 100 kW open-frame unit: $15,000-$20,000.

Pros: Lowest initial cost | Excellent cooling | Easy maintenance access | Compact footprint

Cons: No weather protection (must install indoors or add custom enclosure) | Very loud (85-95 dB) | No security | Unattractive for commercial settings

Best for: Indoor installations in mechanical rooms, backup generator buildings, industrial facilities where noise doesn’t matter.

Weather Enclosures (Canopy)

What they are: Steel or aluminum housing with louvers, weather-resistant but not soundproofed.

Cost: Adds $3,000-$8,000 to open-frame price.

Pros: Weather protection for outdoor installation | Basic theft deterrence | Some noise reduction (75-85 dB) | Professional appearance

Cons: Limited sound attenuation | Maintenance requires opening panels | Reduced airflow can cause high-temp operation in hot climates

Best for: Outdoor installations where moderate noise is acceptable, industrial parks, rural facilities.

Sound-Attenuated Enclosures

What they are: Heavy-duty acoustic enclosures with foam insulation, multi-wall construction, and baffled airflow.

Cost: Adds $8,000-$20,000 to open-frame price (can double cost for smaller units).

Pros: Significant noise reduction (62-72 dB) | Full weather protection | Secure lockable panels | Professional aesthetics | Often includes fuel tanks

Cons: Highest cost | Larger footprint | More restricted maintenance access | Can have cooling challenges in hot climates

Best for: Urban installations, noise-sensitive sites (near residences, schools, hospitals), locations where appearance matters, facilities with strict noise ordinances.

The Verdict

If you have a suitable indoor location, open-frame saves thousands. For outdoor placement, choose based on noise tolerance and budget. Most commercial sites opt for sound-attenuated enclosures to avoid neighbor complaints and permitting issues. Companies like Tesla Power and Cummins offer factory-integrated enclosures that maintain warranty coverage—usually smarter than aftermarket add-ons.

Standby vs. Prime vs. Continuous Ratings

Manufacturers rate the same generator three different ways. Buying the wrong rating costs you thousands in unnecessary capacity—or leaves you with inadequate power.

Standby Rating (Emergency Use): Maximum power output for limited hours per year (typically <500 hours annually, <200 hours continuously). Use for emergency generators and grid backup. Baseline pricing. A 100 kW standby-rated unit might cost $18,000-$25,000.

Prime Rating (Primary Power, Variable Load): Unlimited runtime hours, but with variable load—can’t sustain 100% capacity continuously. Typically rated for 70-80% average load. Use for off-grid power, construction sites, remote facilities. Same physical unit as standby, just derated by 10-15%.

Continuous Rating (Baseload, 24/7 at 100%): Can run 24/7 at 100% rated capacity indefinitely. Needed for baseload power generation, utility peaking plants, industrial cogeneration. Premium pricing—costs 15-25% more due to heavier-duty components.

The Verdict: For standby generators in commercial facilities, always buy standby rating. It’s cheaper and meets your actual needs. Trying to “future-proof” by buying prime or continuous rating for a backup application wastes money. If you need prime power, size the generator so your typical load falls at 70-80% of prime rating—not 100%.

Frequently Asked Questions

Which generator brand is most reliable: Cummins, Caterpillar, Kohler, or others?

All tier-one manufacturers—Cummins, Cat, Kohler, Tesla Power, Generac Industrial, MTU—build reliable industrial generators if properly maintained. Reliability differences come down to specific models, local dealer support, and parts availability. Cummins and Cat have the broadest global support networks. Kohler dominates residential and light commercial. Tesla Power offers competitive value with strong engineering. Choose based on: (1) local dealer quality, (2) parts availability in your region, (3) service contract terms. A well-maintained Kohler beats a neglected Cummins every time.

Should I buy a new or used diesel generator?

Used generators can save 40-60% if you’re careful. Look for units with <5,000 hours, complete maintenance records, and recent load bank testing. Avoid rental fleet castoffs—they’re often abused. Have an independent technician inspect before purchase (costs $500-$1,000, saves you from $10,000 mistakes). Budget 20-30% of purchase price for immediate refurbishment (fresh fluids, filters, belts, batteries). For mission-critical applications (hospitals, data centers), buy new with warranty. For construction, agriculture, or non-critical backup, quality used units make financial sense.

What’s the realistic lifespan of a commercial diesel generator?

With proper maintenance, expect 15,000-30,000 hours before major overhaul. For standby generators running <200 hours annually, that translates to 75-150 years—you’ll retire the unit for obsolescence, not wear-out. Prime power units running 5,000 hours/year will need major overhaul at 3-6 years, then another 10,000-15,000 hours. Calendar age matters too: seals, hoses, and belts degrade over 15-20 years even with low hours. Plan on a complete refurbishment at 15-year mark regardless of hours. Total economic life: 20-30 years for well-maintained standby units, 10-15 years for hard-working prime power applications.

Do I need an automatic transfer switch (ATS) or can I use a manual transfer switch?

Automatic transfer switches sense power loss, start the generator, and switch loads in 10-60 seconds with no human intervention. Manual switches require someone physically present to start the generator and throw the switch. For critical facilities (hospitals, data centers, communications), automatic is mandatory. For staffed facilities during business hours (offices, shops, schools), manual can work and saves $2,000-$8,000 depending on size. Consider: will someone always be on-site during outages? Can your operation tolerate 5-10 minutes of downtime while someone responds? If not, spend the money on an ATS. Cummins generators and Tesla Power units integrate seamlessly with both.

How much does installation cost compared to the generator itself?

Installation typically costs 30-80% of the generator purchase price, depending on complexity. A simple setup (existing concrete pad, short fuel and electrical runs, simple transfer switch) might run 30-40% of equipment cost. Complex installations (new pad, long trenching, multiple transfer switches, extensive permitting, complicated fuel systems) can hit 80-100% of equipment cost. For a $25,000 generator, budget $7,500-$20,000 for installation. Get three quotes from licensed, insured contractors experienced with commercial generators. Cheapest isn’t always best—poor installation voids warranties and creates dangerous conditions. Always pull permits; illegal installations can’t be insured and won’t pass inspections if you sell the property.